Introduction

Measuring instruments are vital tools used to quantify and evaluate physical quantities with precision and accuracy. They play a pivotal role across various fields, from scientific research to industrial processes. These instruments enable us to gauge parameters like length, temperature, pressure, voltage, and more. By converting physical quantities into quantifiable values, they aid in gathering objective data, ensuring consistency and reliability in assessments.

Measuring instruments can be classified into two main categories: analog and digital. Analog instruments provide readings through a scale or dial, while digital instruments display numerical values electronically. The accuracy of these instruments depends on factors like calibration, sensitivity, and resolution. Calibration ensures that measurements are aligned with established standards.

In summary, measuring instruments are essential tools that allow us to obtain precise and consistent measurements of physical properties. They underpin the foundation of scientific inquiry, quality control, and technological advancement, enhancing our understanding of the world and facilitating the development of innovative solutions.

Measuring Instruments Uses

Measuring instruments are employed across a wide range of fields and applications to obtain accurate and reliable data. Some common uses include –

- Scientific Research: Measuring instruments are crucial in scientific studies to gather precise data for experiments, observations, and analyses. They help researchers quantify physical properties and validate hypotheses.

- Industrial Processes: Industries utilize measuring instruments for quality control, process monitoring, and optimization. Instruments such as thermometers, pressure gauges, and flow meters ensure consistent production and adherence to standards.

- Engineering and Construction: Measuring instruments like rulers, levels, and laser distance meters are fundamental in engineering and construction projects to ensure accurate dimensions, alignments, and angles.

- Healthcare: Medical instruments such as thermometers, blood pressure monitors, and heart rate monitors aid in diagnosing and monitoring patients’ conditions, ensuring proper healthcare management.

- Environmental Monitoring: Instruments like weather stations, air quality monitors, and water quality analyzers are employed to assess and manage environmental conditions and changes.

- Astronomy: Telescopes and spectrographs are measuring instruments used in astronomy to observe and quantify celestial phenomena, enhancing our understanding of the universe.

- Electronics and Electrical Engineering: Multimeters, oscilloscopes, and voltage testers help engineers diagnose and troubleshoot electrical circuits and devices.

- Material Testing: Measuring instruments like hardness testers, tensile testers, and spectrometers are used to assess material properties in industries like metallurgy and manufacturing.

- Energy Management: Instruments such as energy meters and power analyzers assist in monitoring and managing energy consumption in residential, commercial, and industrial settings.

- Aviation and Aerospace: Instruments like altimeters, airspeed indicators, and gyroscopes are critical in aviation for navigation, flight control, and safety.

- Automotive Industry: Measuring instruments are used for vehicle testing, emissions monitoring, and quality control in the automotive sector.

- Educational Settings: Measuring instruments are used in educational institutions to teach students about scientific principles and measurement techniques.

- Food Industry: Instruments like pH meters and refractometers help maintain quality and safety standards in food production.

- Forensics: Measuring instruments play a role in crime scene investigation, analyzing evidence, and reconstructing events.

- Research and Development: Measuring instruments aid in the development of new products, technologies, and innovations by providing accurate data for analysis and improvement.

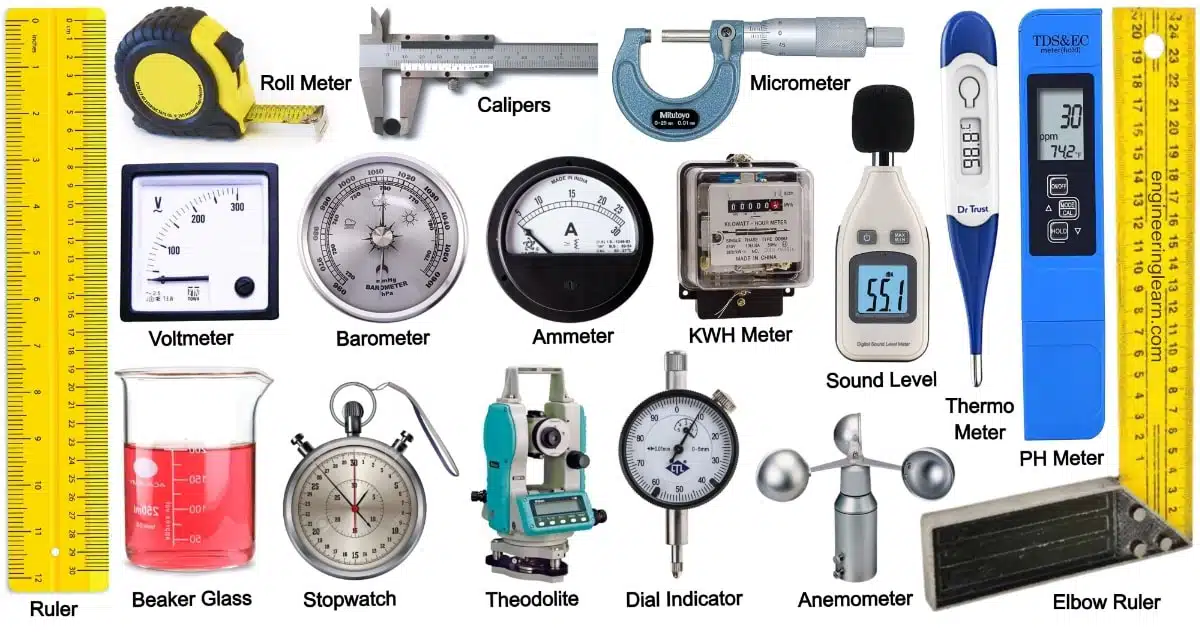

List of Measuring Instruments

1. Steel Scale

A steel scale, commonly known as a steel ruler, is a linear measuring instrument crafted from stainless steel, ensuring durability and accuracy. It’s marked with units like millimeters and centimeters, allowing precise measurements in various applications.

The least count of a steel scale depends on its divisions between markings. For example, if the scale is divided into millimeters, its least count would be 0.5 millimeters. This means it can measure lengths with an accuracy of 0.5 millimeters. Steel scales are popular for their robustness and straightforward usage, making them indispensable tools in fields like engineering, architecture, and workshops for accurate length measurements.

2. Roller Meter or Inch Tape

A roller meter, also known as an inch tape, is a flexible measuring tool used to gauge distances. It consists of a coiled strip of material, often marked with inches or centimeters, wound within a compact housing. As the tape is extended along the object being measured, a rolling mechanism helps keep track of the length. Roller meters are versatile, portable, and widely used in construction, sewing, and everyday tasks that require accurate linear measurements.

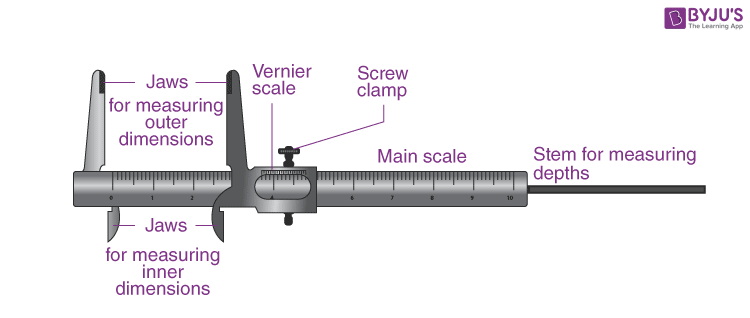

3. Vernier Caliper

A vernier caliper is a precision measuring tool used to gauge the dimensions of objects with high accuracy. It comprises a main scale and a sliding vernier scale. The main scale provides a rough measurement, while the vernier scale, with finer divisions, allows for precise readings. When the two scales align, the measurement is taken from the vernier scale’s zero point. Vernier calipers are used in various fields, including engineering and science, for measuring lengths, diameters, and depths of objects with exceptional precision.

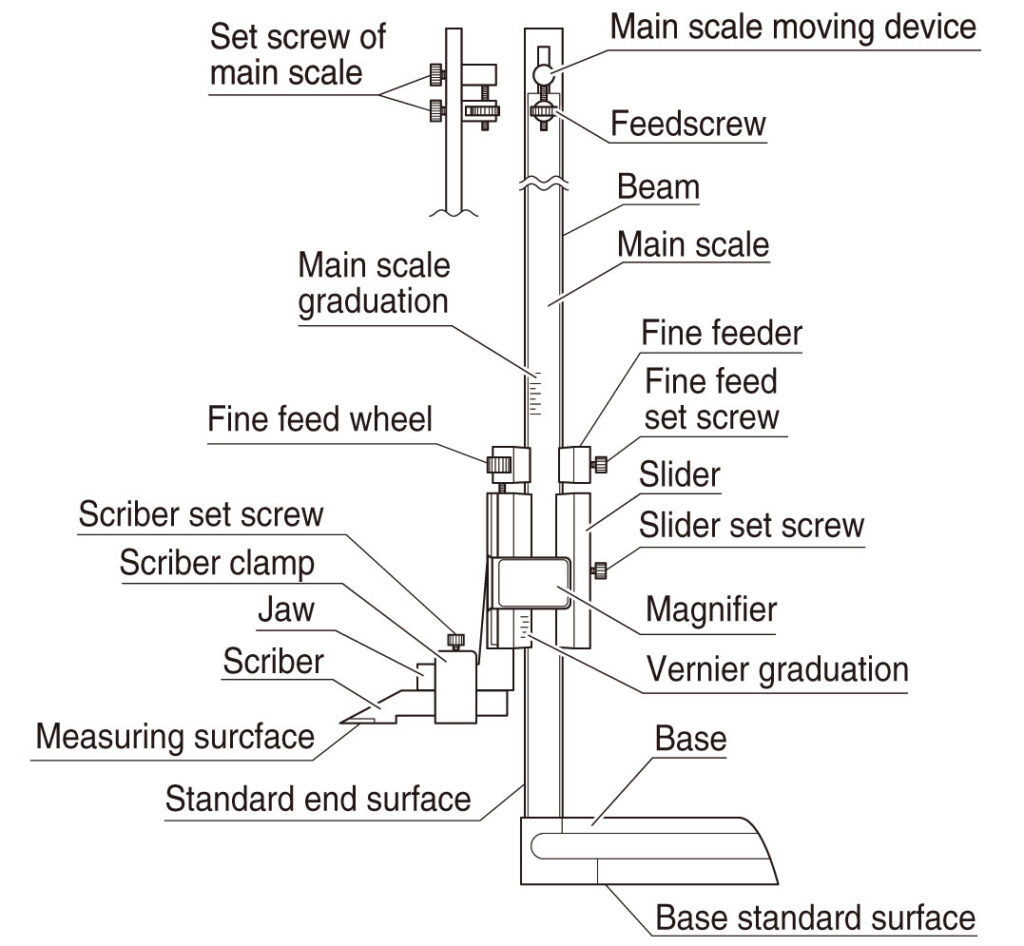

4. Height Gauge

A height gauge is a measurement tool designed to determine the vertical distance between a reference point and a surface or object. It consists of a vertical column with a measuring scale and a movable arm that holds a probe or a measuring instrument. By positioning the arm against the reference point and lowering the probe to touch the object’s surface, the vertical measurement can be read from the scale. Height gauges are essential in industries like manufacturing and machining to ensure accurate heights, depths, and steps in various components.

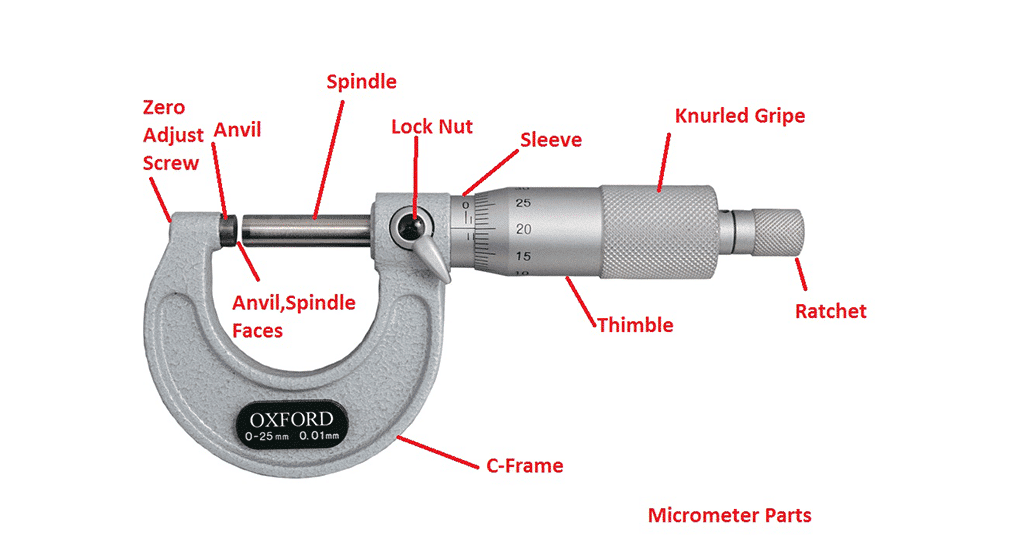

5. Micrometer

A micrometer is a precision measuring instrument used to determine small distances with high accuracy. It consists of a calibrated screw that moves a spindle and anvil toward or away from the object being measured. The measurement is read from a scale on the sleeve and an additional scale on the rotating thimble, which gives fractional increments. Micrometers come in various types, including outside, inside, and depth micrometers, and are indispensable in industries like manufacturing, engineering, and metrology for precise measurements of dimensions such as thickness, diameter, and depth.

6. Multimeter

A multimeter is an electronic measuring instrument that combines several functions into one device. It typically measures voltage, current, and resistance, and can also test continuity and diode functionality. It features a digital or analog display to show the measurement values. Multimeters are used in electronics, electrical engineering, and maintenance tasks to diagnose and troubleshoot circuits, check the health of electrical components, and ensure safety. They provide an efficient way to gather diverse electrical measurements using a single tool, making them essential for professionals and hobbyists alike.

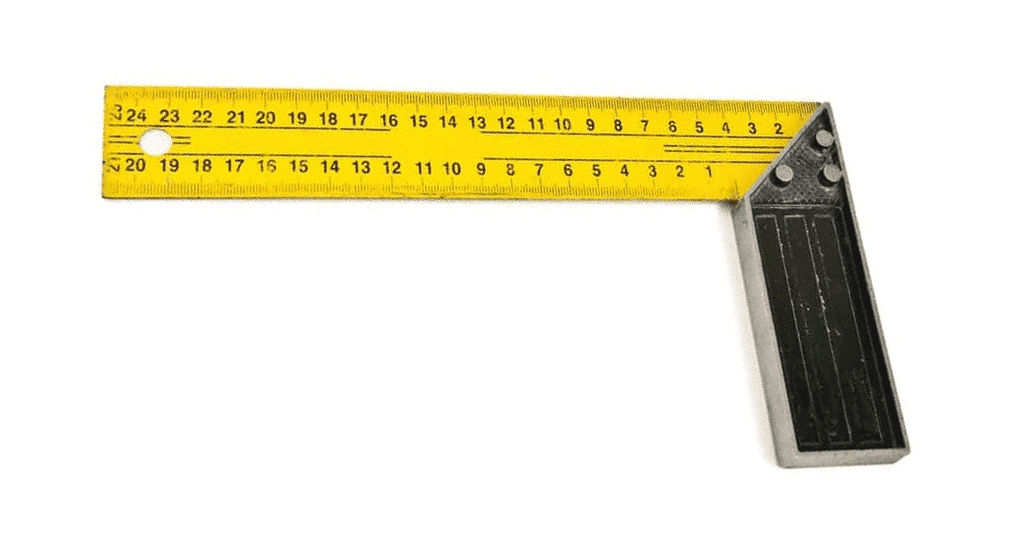

7. Elbow Ruler

An elbow ruler, also known as a bevel protractor or bevel square, is a measuring tool used to determine and set angles. It typically consists of two arms connected at a hinge, allowing them to be adjusted to different angles. The arms are marked with degree measurements, enabling accurate angle readings. Elbow rulers are employed in woodworking, metalworking, and engineering for tasks that require precise angle measurements, such as cutting, fitting, and assembling components at specific angles for optimal results.

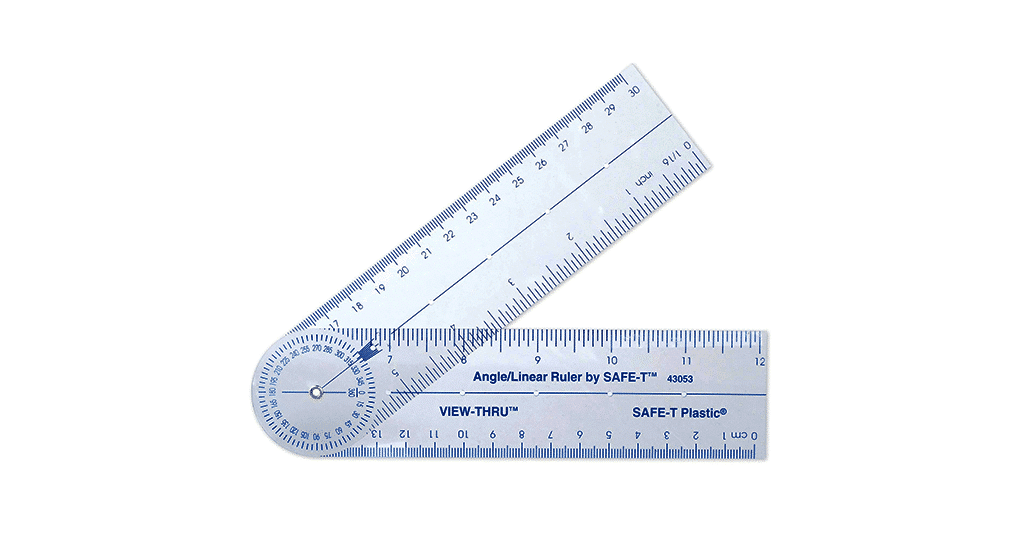

8. Angle Ruler

An angle ruler, commonly known as a protractor, is a measuring tool used to determine angles between two lines or surfaces. It features a circular or semicircular design with degree markings, allowing users to align it with an angle and read the measurement. Protractors come in various forms, including traditional circular versions and digital versions with LCD displays. They are essential tools in geometry, construction, and engineering for accurately measuring and drawing angles, ensuring proper alignment and precision in a wide range of applications.

9. Compass

A compass is a navigational instrument designed to measure angles or directions relative to magnetic north. In this context, a compass serves as a basic tool for determining angles in navigation, cartography, and outdoor activities. It usually consists of a magnetic needle that aligns with the Earth’s magnetic field, indicating north, and a rotating bezel with degree markings to measure angles. While its primary purpose is direction finding, it’s also used for quick angle approximations, making it a versatile tool for basic angle measurements in various contexts.

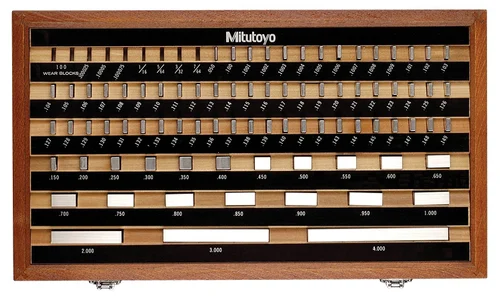

10. Slip Gauge

A slip gauge, also known as a gauge block or gage block, is a precision measurement tool used to establish highly accurate dimensions. It comprises a set of metal blocks made with precise lengths, often in metric or imperial units. These blocks are manufactured to extremely tight tolerances and can be stacked or combined to create specific measurements. Slip gauges are vital in calibration labs, manufacturing, and metrology for verifying the accuracy of measuring instruments, setting up machinery, and ensuring standardization across various industries.

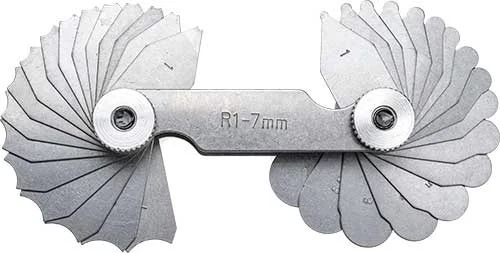

11. Radius Gauge

A radius gauge is a measuring tool used to determine the radius of a curved or rounded object. It consists of a set of thin, flat leaves or blades, each marked with a specific radius value. By selecting the leaf that fits snugly against the curve, the radius can be read directly from the gauge. Radius gauges are indispensable in industries like metalworking, woodworking, and engineering for accurately replicating and measuring curves, ensuring proper profiles and dimensions in various applications.

12. Thread Gauge

A thread gauge is a measurement tool designed to assess the characteristics of screw threads. It comes in various types, such as ring gauges and plug gauges, each used to check external and internal threads, respectively. Thread gauges ensure that manufactured threads conform to established standards, guaranteeing proper fit and interchangeability of threaded components. They are widely employed in industries like manufacturing, automotive, and aerospace, where precision threading is essential for secure assemblies and smooth operations.

13. Dial Indicator

A dial gauge, also known as a dial indicator, is a precision measuring instrument used to detect and quantify small linear displacements or deviations. It features a movable plunger that responds to changes in position. The displacement is displayed on a dial with a needle, providing precise readings. Dial gauges are essential in industries like manufacturing, machining, and quality control to ensure accurate measurements, assess tolerances, and monitor variations in dimensions, contributing to the precision and reliability of mechanical processes and components.

14. Level Gauge

A level gauge is a measurement tool used to determine the level of a liquid or a granular substance in a container or a vessel. It consists of a transparent or translucent tube connected to the container, allowing the substance’s level to be observed visually. The level can be read directly from the height of the substance within the tube. Level gauges are widely used in industries such as chemical, oil, and food processing to monitor and control fluid levels in tanks and vessels, ensuring proper operations and preventing overflows or shortages.

15. pH Meter

A pH meter is a scientific instrument used to measure the acidity or alkalinity (pH level) of a liquid substance. It comprises a probe with a specialized glass electrode that reacts to hydrogen ion concentration in the solution. The meter then translates this reaction into a pH value, displayed on a digital screen. pH meters are essential in laboratories, environmental monitoring, and industries like agriculture and food processing to ensure optimal conditions, quality control, and accurate analysis of solutions’ acidity or alkalinity.

16. Thermometer

A thermometer is a measuring instrument used to gauge temperature. It typically consists of a temperature-sensitive sensor (such as mercury, alcohol, or digital sensor) and a scale that provides temperature readings. When the sensor interacts with the heat of the environment, it undergoes expansion or contraction, reflecting the temperature change. Thermometers come in various types, including mercury, digital, infrared, and thermocouple thermometers. They are employed across industries, healthcare, meteorology, and scientific research to monitor and control temperature variations, ensuring safety, accuracy, and optimal conditions in various settings.

17. Manometer

A manometer is a pressure-measuring device used to determine fluid pressure in closed systems. It typically consists of a U-shaped tube partially filled with a liquid, often mercury or water, and connected to the system being measured. The difference in fluid levels in the two arms of the U-tube indicates the pressure difference between the system and the atmosphere. Manometers are essential tools in various applications, from monitoring gas pressures in industrial processes to assessing blood pressure in medical settings, providing valuable insights into pressure variations.

18. Voltmeter

A voltmeter is an electrical measuring instrument used to quantify the voltage difference between two points in an electric circuit. It typically features a scale or digital display that indicates the voltage in volts. Voltmeters can be analog or digital and come in various types, including analog panel meters, handheld digital multimeters, and specialized high-voltage voltmeters. They are crucial for diagnosing electrical problems, ensuring proper voltage levels, and maintaining the safety and efficiency of electrical systems in fields such as electronics, engineering, and maintenance.

19. Ammeter

An ammeter is an electrical measuring device used to determine the current flowing through a circuit. It’s designed to be connected in series with the circuit, allowing the current to pass through it. The ammeter typically displays the current value in amperes on an analog or digital scale. Ammeters are essential tools for assessing and monitoring electrical currents in various applications, from electronics and power distribution to industrial machinery. They aid in maintaining the functionality and safety of electrical systems by ensuring proper current levels and detecting anomalies.

20. Lux Meter

A lux level meter, also known as a light meter, is a device used to measure the intensity of light in a specific area, typically in units called lux. Lux represents the amount of light that falls on a surface per unit area. Light meters are employed in various fields, including photography, interior design, and industrial settings, to ensure proper lighting conditions for tasks, energy efficiency, and compliance with safety regulations. They help in maintaining appropriate illumination levels for optimal visibility, comfort, and productivity.

21. Weighing Scale

A weighing scale is a measurement instrument used to determine the mass or weight of an object. It operates by measuring the force exerted by an object due to gravity. There are various types of weighing scales, including mechanical and digital scales, with different weight capacities and precision levels. Weighing scales are indispensable in industries such as manufacturing, agriculture, and healthcare, ensuring accurate measurements for quality control, portioning, and monitoring. They also play a vital role in personal and commercial settings for tracking weight changes and adhering to weight-related requirements.

22. kWh Meter

A kWh (kilowatt-hour) meter, also known as an electric meter, is a device used to measure and record the amount of electrical energy consumed by a building, facility, or appliance. It calculates energy usage in kilowatt-hours, which is the product of power (in kilowatts) and time (in hours). kWh meters are vital for utility billing, energy management, and tracking power consumption trends. They play a crucial role in promoting energy efficiency, allowing consumers and businesses to monitor their electricity usage and make informed decisions to conserve energy and reduce costs.

23. Beaker Glass

A beaker, often made of borosilicate glass, is a cylindrical vessel with a flat bottom and spout used for measuring and holding liquids. While not as precise as dedicated measuring tools, it provides approximate volume measurements. Graduations on the side aid in estimation. Beakers are versatile in laboratories, facilitating mixing, heating, and transferring liquids. However, they’re not ideal for accurate measurements due to the lack of precise calibration. For precise volume measurements, graduated cylinders or volumetric flasks are preferred. Beakers excel in general-purpose applications requiring basic volume estimates during experiments and procedures.

24. Stopwatch

A stopwatch is a timekeeping device used to measure elapsed time intervals with precision. It features a start, stop, and reset function, often accompanied by lap or split time capabilities. Stopwatches come in both analog and digital forms, commonly used in sports, scientific experiments, and various timing-sensitive tasks. They allow users to accurately track durations, such as race times, experiment durations, or other time-based events. Stopwatches are invaluable tools in industries like athletics, research, and industrial processes where precise timing is crucial.

25. Hygrometer

A hygrometer is a measuring instrument designed to determine the humidity level or moisture content in the air. It comes in various types, including psychrometers, capacitive hygrometers, and mechanical hygrometers. These devices measure humidity by assessing factors like temperature, pressure, and electrical capacitance. Hygrometers are essential in meteorology, industrial processes, and indoor environments, providing critical information about moisture levels for maintaining optimal conditions, preventing mold growth, and ensuring comfortable and safe surroundings. They play a vital role in fields like agriculture, HVAC, and material testing.

26. Speedometer

A speedometer is a device in vehicles used to display the current speed at which the vehicle is traveling. It’s typically located on the dashboard and employs various mechanisms to gauge speed, such as a rotating cable connected to the wheels or electronic sensors. The displayed speed is usually in miles per hour (mph) or kilometers per hour (km/h). Speedometers are crucial for safe driving, as they allow drivers to monitor their speed and adhere to speed limits, contributing to road safety and traffic regulations.

Measuring Instruments Supplier

Here are the 20 top suppliers of measuring instruments –

- Fluke Corporation

- HTC Measuring Technologies

- Agilent Technologies

- Yokogawa Electric Corporation

- Mitutoyo Corporation

- Honeywell

- Tektronix

- Testo SE & Co. KGaA

- Brüel & Kjær

- Hanna Instruments

- A&D Company, Limited

- Extech Instruments

- Omega Engineering

- OMRON Corporation

- Wika

- Rohde & Schwarz

- Lutron Electronic Enterprise Co., Ltd.

- Ametek, Inc.

- Leica Geosystems AG

- TSI Incorporated

Conclusion

Measuring instruments are the backbone of precision and accuracy across diverse industries and scientific endeavors. These tools enable us to quantify physical properties, gather data, and make informed decisions. From simple rulers to sophisticated digital devices, measuring instruments have transformed the way we understand and interact with the world around us. They play an indispensable role in quality control, research, manufacturing, and everyday life, ensuring consistency, reliability, and safety.

As technology continues to evolve, measuring instruments continue to advance, offering higher levels of accuracy, automation, and integration. The future holds exciting possibilities for more efficient and accessible measurement solutions, contributing to innovation and progress in fields ranging from medicine and engineering to environmental conservation and space exploration. With each precise measurement taken, measuring instruments serve as a testament to human curiosity, ingenuity, and our constant quest for understanding the intricacies of our universe.

FAQ’s

What are precision measuring instruments?

Precision measuring instruments are tools designed to provide highly accurate and reliable measurements of physical quantities such as length, angle, temperature, and more. These instruments are crafted with meticulous attention to detail, using advanced technologies and materials to minimize errors and uncertainties. They are crucial in fields like manufacturing, research, and engineering, where precision is paramount for ensuring product quality, meeting specifications, and conducting precise scientific experiments. Precision measuring instruments offer finer graduations, tighter tolerances, and superior calibration to achieve measurement accuracy within narrow limits, contributing to enhanced accuracy and quality control in various applications.

What are some instruments used for measuring humidity?

Some instruments used for measuring humidity include hygrometers, psychrometers, capacitive humidity sensors, and dew point meters. These devices assess moisture content in the air by analyzing factors like temperature, pressure, and electrical capacitance, providing valuable information for maintaining optimal conditions in various environments and applications.

Which measuring instrument is used to master other instruments?

A reference standard or calibration instrument is used to master other measuring instruments. It’s a highly accurate device with precisely known measurements. Instruments are compared to these standards to ensure accuracy and calibration. They play a pivotal role in maintaining the accuracy and reliability of measurement tools across various industries.

Why do measuring instruments need calibration?

Measuring instruments need calibration to ensure their accuracy and reliability. Over time, factors like wear, temperature, and environmental conditions can cause deviations from standard measurements. Calibration compares instrument readings to known standards, correcting any discrepancies. This guarantees that measurements are consistent, precise, and adhere to established accuracy criteria.

Which instruments are the most accurate for measuring liquids?

Volumetric glassware, such as pipettes, burettes, and volumetric flasks, are the most accurate instruments for measuring liquids. They are precision-calibrated to deliver or contain specific volumes with high accuracy. These instruments are essential in laboratories, research, and analytical processes where precise liquid measurements are crucial for accurate results.