In the world of manufacturing, precision is paramount. When it comes to producing plastic and metal parts, molds play a crucial role in achieving the desired accuracy and consistency. To procure the right mold for your project, it’s essential to draft a Request for Quotation (RFQ) that contains detailed and precise mold specifications. In this article, we’ll delve into the essentials of crafting an RFQ for molds, emphasizing the importance of understanding and conveying accurate mold specifications.

The Significance of Mold Specifications for Request for Quotation (RFQ)

Mold specifications are the cornerstone of an RFQ. They provide potential suppliers with a clear and detailed understanding of what you need, ensuring that their quotes are accurate and competitive. Ambiguity or incomplete information in an RFQ can lead to misunderstandings, delays, and cost overruns. Therefore, understanding mold specifications is crucial for both the buyer and the supplier.

Key Elements of Mold Specifications

When drafting an RFQ for molds, consider including the following key elements:

1. Material Requirements

Specify the type of material you intend to use for the molded parts. Whether it’s plastic, metal, or another material, detailing its characteristics and properties is vital. Be clear about any special requirements, such as the need for food-grade materials or specific certifications.

2. Mold Type

Indicate the type of mold you require. Common options include injection molds, die-casting molds, blow molds, and compression molds. Each type is suited to different production methods and materials, so clarity here is crucial.

3. Mold Size and Tolerances

Define the dimensions of the mold, including length, width, height, and any critical tolerances. Precise measurements are vital to ensure the final parts meet your requirements.

4. Surface Finish and Texture

Detail any specific surface finishes or textures required for the molded parts. This can include gloss levels, texture patterns, and other cosmetic considerations.

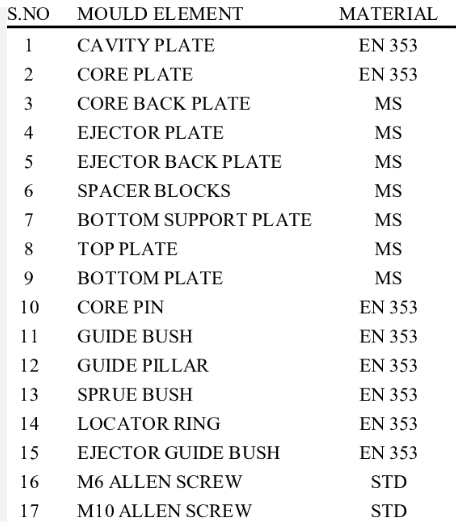

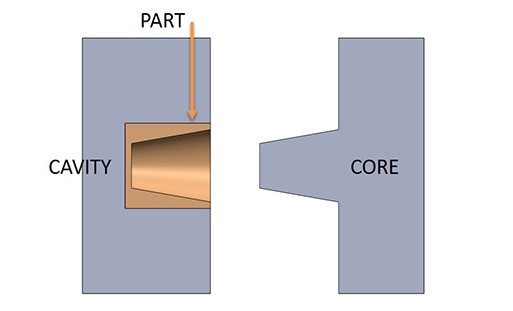

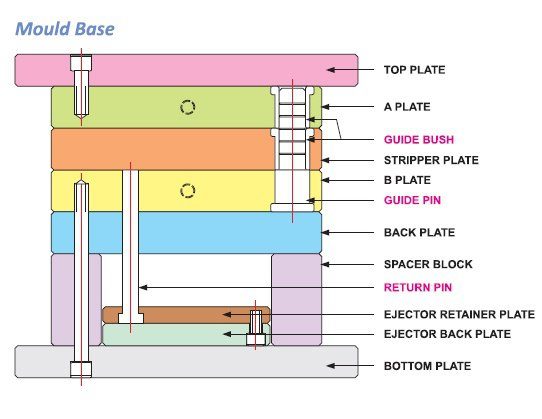

5. Cavities and Cores

Specify the number of cavities and cores needed in the mold. This information is essential for determining production capacity and cost.

6. Expected Production Volume

Estimate the quantity of parts you intend to produce. Suppliers need this information to assess the mold’s durability and plan production schedules.

7. Quality Standards

Outline any quality standards or certifications the mold must meet, such as ISO standards, industry-specific requirements, or your internal quality guidelines.

8. Part Complexity

Describe the complexity of the parts to be produced. This includes details about undercuts, side actions, or any intricate features that may affect mold design and cost.

9. Mold Lifespan

Specify the expected mold lifespan. Different molds have varying lifespans based on material and production volume.

10. Delivery Requirements

Indicate your preferred delivery timeline. Clear expectations regarding lead times and delivery schedules are crucial to avoid delays in your project.

Clarity and Precision in Mold Specifications

When drafting mold specifications in an RFQ, clarity and precision are non-negotiable. Ambiguities or vague descriptions can lead to misunderstandings and inaccurate quotes. Here are some tips to ensure your mold specifications are as clear as possible –

- Use Industry Terminology: Employ industry-standard terminology and symbols to convey your requirements accurately.

- Provide Visual Aids: Include drawings, sketches, or CAD files to illustrate your expectations.

- Refer to Samples: If possible, provide physical samples of the desired parts or molds to serve as a reference.

- Be Detailed: Don’t overlook small but crucial details, such as draft angles, gate locations, ejection systems, and cooling channels.

- Consult Experts: If you’re uncertain about any aspect of mold specifications, consult with experts or experienced mold designers to ensure accuracy.

Conclusion

Request for Quotation (RFQ) documents are the bridge between your requirements and potential suppliers’ capabilities. When it comes to molds, understanding and conveying precise mold specifications is vital. Clarity and accuracy in your RFQ not only help you receive competitive and accurate quotes but also lay the foundation for successful collaboration with your mold supplier. It’s an investment in precision that pays off in the form of high-quality, cost-effective molded parts, and a streamlined production process.

Frequently Asked Questions – Request for Quotation (RFQ)

What is a Request for Quotation (RFQ)?

An RFQ is a formal document used by organizations to solicit price quotations from potential suppliers for the procurement of goods or services. It outlines the specifications, terms, and conditions for the desired products or services.

How is an RFQ different from an RFP or RFI?

An RFQ is primarily used to request price quotations for well-defined products or services. An RFP (Request for Proposal) seeks detailed proposals with potential solutions, while an RFI (Request for Information) is used to gather information about suppliers and their capabilities.

What should an RFQ include?

An RFQ typically includes a description of the products or services required, technical specifications, quantity, quality standards, delivery requirements, terms of payment, and any other relevant terms and conditions.

How do I find potential suppliers for my RFQ?

Potential suppliers can be identified through industry directories, trade associations, online marketplaces, or by requesting recommendations from colleagues and industry experts. Many organizations maintain a list of approved suppliers.

What is the RFQ response timeline?

The response time for an RFQ varies depending on the complexity of the request and the industry. Generally, suppliers are given a reasonable amount of time to prepare and submit their quotes, often ranging from two weeks to a month.

How should I evaluate RFQ responses?

Evaluate RFQ responses based on factors such as price, quality, delivery time, supplier reputation, and compliance with the specified requirements. A structured evaluation process may include scoring criteria to make an informed decision.

Is it necessary to disclose the budget in an RFQ?

It is not always necessary to disclose the budget in an RFQ. However, providing a budget range or target price can help suppliers tailor their proposals and ensure that their quotes are within the buyer’s financial expectations.

Can I negotiate with suppliers after receiving RFQ responses?

Yes, negotiations are common after receiving RFQ responses. You can discuss terms, pricing, and any necessary adjustments with suppliers to reach a mutually beneficial agreement.

How many suppliers should I send an RFQ to?

The number of suppliers to approach with an RFQ depends on your specific requirements and industry. It’s advisable to send the RFQ to a sufficient number of qualified suppliers to ensure competitive pricing and a reliable source of supply.

Frequently Asked Questions – Mold Specifications

What are mold specifications?

Mold specifications are detailed descriptions of the requirements for a mold used in manufacturing to produce parts or products. They include information about materials, dimensions, tolerances, surface finishes, and other critical details.

Why are mold specifications important in manufacturing?

Mold specifications are crucial because they provide precise instructions to mold designers and manufacturers, ensuring that the mold is built to meet the desired part requirements. Clear specifications help prevent misunderstandings, reduce errors, and enhance the quality of the molded parts.

What key elements should be included in mold specifications?

Important elements to include in mold specifications are material requirements, mold type, size and tolerances, surface finish, number of cavities and cores, expected production volume, quality standards, part complexity, mold lifespan, and delivery requirements.

How can I ensure that my mold specifications are clear and precise?

To ensure clarity and precision in mold specifications, use industry-standard terminology and symbols, provide visual aids like drawings or CAD files, refer to physical samples if available, and be detailed in describing aspects like draft angles, gate locations, ejection systems, and cooling channels.

Can I provide too much detail in mold specifications?

While it’s important to provide comprehensive information, excessive detail can sometimes be overwhelming. It’s best to strike a balance by including necessary details that convey your requirements clearly without overcomplicating the document.

How do I determine the appropriate mold lifespan for my project?

The mold lifespan depends on factors like the material used, the expected production volume, and the type of parts being produced. Consulting with experienced mold designers and considering the cost-effectiveness of mold maintenance and replacement can help determine the appropriate lifespan.

What if I’m uncertain about certain aspects of mold specifications?

If you’re uncertain about specific mold specifications, consider consulting with experts or experienced mold designers who can provide guidance and ensure your requirements are accurate.

Can mold specifications change during the manufacturing process?

Mold specifications can change, but any modifications should be communicated and agreed upon by both the buyer and the supplier to avoid disruptions in the manufacturing process and additional costs.

This is such an important reminder and one that I needed to hear today Thank you for always providing timely and relevant content

Thanks