Overview

In the world of electrical and electronic engineering, connectivity is key. From powering complex machinery to enabling data transmission in sophisticated devices, connectors are the unsung heroes that facilitate the flow of power and information. While standardized connectors serve most purposes, there are instances when specialized applications or custom designs demand a more tailored solution. Enter the custom 24 pin connector – a versatile component designed to meet unique requirements and deliver precise performance. In this comprehensive article, we will explore the world of custom 24 pin connectors, their applications, benefits, and the process of designing and manufacturing them.

Understanding the Basics of Connectors

Before delving into custom 24 pin connectors, it’s crucial to grasp the fundamentals of connectors in general. Connectors are devices used to establish an electrical or electronic connection between two or more components. They come in various shapes, sizes, and configurations, each suited to specific applications.

Connectors typically consist of the following key elements –

- Contacts: These are the conductive elements within the connector that physically make electrical contact with corresponding contacts in the mating connector or device.

- Housing: The housing encases the contacts and provides physical protection, alignment, and insulation.

- Locking Mechanism: Many connectors feature a locking mechanism that ensures a secure and reliable connection.

- Keying: Keying prevents mismating by ensuring that the connector can only be inserted in one orientation.

- Backshell: Some connectors have a backshell or cable clamp to secure the attached cables and provide strain relief.

- Number of Pins: Connectors can have various numbers of pins or contacts, ranging from just a few to several hundred or more, depending on the application.

Working Principle of 24 Pin Connectors

The working principle of 24-pin connectors involves their ability to establish electrical connections between multiple pins or contacts. Here’s a step-by-step explanation of the working principle –

1. Contact Arrangement:

- A 24-pin connector consists of 24 conductive pins or contacts arranged in a specific pattern within a housing.

2. Insertion:

- To establish a connection, the connector is inserted into a mating connector or receptacle with a corresponding pin arrangement.

3. Mechanical Alignment:

- As the connector is inserted, mechanical features, such as keying or notches, ensure that it can only be inserted in the correct orientation, preventing mismating.

4. Contact Engagement:

- When fully inserted, the connector’s pins make physical contact with the corresponding pins or contacts in the mating connector.

5. Electrical Conductivity:

- Electrical conductivity is achieved through the metal-to-metal contact between the pins. This allows for the transmission of electrical signals, power, or data.

6. Secure Connection:

- Many connectors include a locking mechanism that secures the connection, preventing accidental disconnection due to vibrations or movement.

7. Insulation and Protection:

- The connector housing provides insulation and protection for the pins and the connection, preventing short circuits and damage.

8. Reliable Transmission:

- The connector is designed to maintain reliable electrical connections, even in challenging environments with factors like vibrations, temperature variations, and moisture.

9. Disconnection:

- When disconnecting, the connector is typically unlocked, and it can be safely removed from the mating connector.

10. Versatility: – Depending on the specific application, 24-pin connectors can be used for a variety of purposes, including power distribution, data transmission, and signal routing.

11. Customization: – Custom 24-pin connectors can be tailored to meet the unique requirements of different applications, ensuring they provide the necessary functionality.

Types of 24 Pin Connectors

Here are some common types of 24 pin connectors explained in short, presented in a step-by-step format –

- D-sub Connectors (DB-24)

- D-sub connectors come in various sizes, including the DB-24, which features 24 pins.

- They are typically used for data transmission and come in both male and female versions.

- DB-24 connectors are commonly found in computer and industrial applications.

2. Power Supply Connectors (ATX 24-pin)

- ATX power supply connectors have 24 pins and are used to provide power to motherboards in desktop computers.

- They supply various voltages and currents required for the motherboard and its components.

- The 24-pin design includes a detachable 4-pin section, making it backward compatible with older 20-pin connectors.

3. Ethernet Connectors (RJ45 24-pin)

- RJ45 connectors, often associated with Ethernet cables, have 8 pins arranged in a 24-pin housing.

- They are used for network connections, transmitting data between computers, routers, and switches.

- RJ45 connectors are a standard in networking.

4. Industrial Circular Connectors (24-pin M23)

- M23 connectors are circular connectors with 24 pins.

- They are designed for industrial applications and provide reliable connections in harsh environments.

- M23 connectors are commonly used in automation and robotics.

5. Audio/Video Connectors (24-pin HDMI, DVI, VGA)

- HDMI, DVI, and VGA connectors can have 24 pins or more for transmitting audio and video signals.

- They are used for high-definition displays, projectors, and audiovisual equipment.

- HDMI connectors, in particular, are widely used in home theaters and digital displays.

6. Automotive Connectors (24-pin Automotive Connectors)

- In the automotive industry, 24-pin connectors are used for various purposes, including data communication and power distribution.

- These connectors are designed to withstand automotive conditions, such as vibrations and temperature variations.

- Automotive connectors may include connectors for sensors, control units, or lighting systems.

7. Military and Aerospace Connectors (MIL-DTL-38999, 24-pin)

- MIL-DTL-38999 connectors with 24 pins are rugged and reliable connectors used in military and aerospace applications.

- They provide secure connections in harsh environments and are designed to meet stringent standards.

- These connectors are used in avionics, communication systems, and more.

8. Fiber Optic Connectors (24-fiber MTP/MPO)

- MTP/MPO connectors with 24 fibers are used for high-density fiber optic connections.

- They are employed in data centers and telecommunications for high-speed data transmission.

- MTP/MPO connectors are known for their efficiency in handling multiple optical fibers.

9. Circular Connectors (24-pin Circular Connectors)

- Circular connectors come in various sizes and pin configurations, including 24-pin versions.

- They are used in diverse applications, such as medical devices, instrumentation, and industrial equipment.

- Circular connectors provide secure and reliable connections.

10. Custom Connectors (Tailored to Specific Applications)

Custom 24-pin connectors are designed to meet unique application requirements. – They can vary in terms of pin arrangement, size, and specifications to match the specific needs of the equipment or system they serve. – Custom connectors are often used in specialized industrial, medical, and scientific applications.

The Versatility of 24 Pin Connectors

The term “24 pin connector” refers to a connector with 24 conductive pins or contacts. While connectors with 24 pins are not as common as, say, 2 or 3 pin connectors, they offer a level of versatility that makes them ideal for specialized applications. Here’s why –

1. Sufficient Contacts for Many Purposes

With 24 pins, these connectors provide ample connections for various purposes. They can carry power, signals, data, and more simultaneously, making them suitable for applications that require multiple functions.

2. Flexibility in Pin Arrangement

Custom 24 pin connectors can have their pins arranged in different configurations, such as single or double rows, which allows for versatility in design and functionality.

3. Adaptable to Complex Systems

They are well-suited for complex systems and equipment that require interconnections between numerous components, such as industrial machinery, medical devices, and aerospace systems.

4. Compatibility with Standardized Connectors

In some cases, 24 pin connectors can be designed to be compatible with standardized connectors, offering a bridge between specialized and standard components.

5. Future-Proofing

Having additional pins can future-proof a design by allowing for potential upgrades or expansion of features without the need for a complete redesign.

Applications of Custom 24 Pin Connectors

Custom 24 pin connectors find applications across a broad spectrum of industries and sectors. Their versatility and adaptability make them valuable in scenarios where standard connectors may not suffice. Here are some notable applications –

1. Industrial Machinery

In the industrial sector, custom 24 pin connectors are used in machinery and automation systems. They facilitate the transmission of power, control signals, and data within complex manufacturing setups.

2. Medical Devices

The medical field often requires connectors that can handle a combination of power, data, and signal connections. Custom 24 pin connectors are employed in medical devices such as diagnostic equipment, patient monitors, and imaging systems.

3. Aerospace and Defense

In the aerospace and defense industries, reliability is paramount. Custom 24 pin connectors are used in avionics, radar systems, and communication equipment to ensure secure and uninterrupted connectivity.

4. Telecommunications

Telecommunication equipment, including base stations and network infrastructure, relies on connectors that can manage numerous connections simultaneously. Custom 24 pin connectors offer a solution for these complex systems.

5. Renewable Energy

In renewable energy applications, such as solar inverters and wind turbines, custom connectors are used to link various components, ensuring efficient power transmission and control.

6. Automotive Technology

Custom 24 pin connectors are found in automotive technology, where they enable connections for vehicle control systems, navigation, entertainment, and safety features.

7. Robotics

The robotics industry utilizes custom connectors to connect sensors, motors, and control systems within robots and automated machinery.

8. Data Centers

Data centers rely on connectors that can handle high-speed data transmission, power distribution, and networking. Custom 24 pin connectors can be tailored to meet the specific demands of these environments.

9. Scientific Instruments

Custom connectors are essential in scientific instruments and laboratory equipment where precision and reliability are critical.

10. Entertainment and Broadcasting

In the entertainment and broadcasting industry, custom connectors are used in audio and video equipment, ensuring seamless signal transmission.

The Advantages of Custom 24 Pin Connectors

Custom 24 pin connectors offer several distinct advantages over standard connectors, making them a preferred choice in specialized applications –

1. Tailored to Specific Needs

Custom connectors are designed to meet the exact requirements of a particular application. This means that they can accommodate unique pin arrangements, signal types, and environmental conditions.

2. Optimal Performance

Because they are purpose-built, custom connectors often deliver optimal performance. They are engineered to provide the required electrical characteristics, including impedance, voltage, and current ratings.

3. Enhanced Reliability

Custom connectors are designed with reliability in mind. They undergo rigorous testing to ensure they can withstand the demands of their intended environment, whether it’s extreme temperatures, vibrations, or moisture.

4. Space Efficiency

Custom connectors can be designed to fit specific space constraints, maximizing the use of available real estate on a circuit board or within an enclosure.

5. Reduced Mating Challenges

In applications where multiple connectors need to be mated and unmated frequently, custom connectors can be designed with features that simplify this process, reducing the risk of errors and damage.

6. Cost-Effective in the Long Run

While custom connectors may have higher initial development costs, they can be more cost-effective in the long run by reducing maintenance, downtime, and the need for additional components or adapters.

7. Future-Proofing

Custom connectors can be designed with future upgrades and expansions in mind, potentially saving on redesign costs down the line.

Designing and Manufacturing Custom 24 Pin Connectors

Designing and manufacturing custom 24 pin connectors is a highly specialized process that involves several key steps –

1. Define Requirements

The process begins with a thorough understanding of the application’s requirements. This includes specifying the number and arrangement of pins, electrical characteristics, and environmental conditions.

2. Conceptual Design

Engineers create a conceptual design that outlines the connector’s form, function, and key features. This stage often involves collaboration between design, electrical, and mechanical teams.

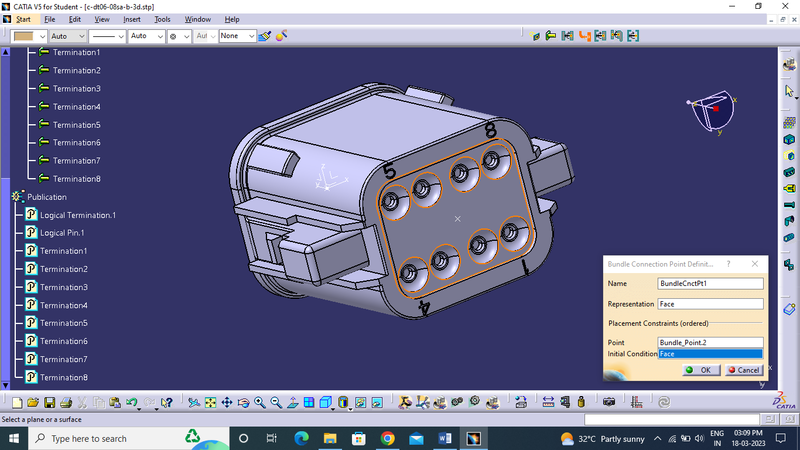

3. Prototyping

Prototyping allows for the testing of the connector’s performance and fit within the application. It may involve the creation of 3D-printed models or small-batch prototypes.

4. Material Selection

The choice of materials is critical, especially for connectors exposed to harsh environments. Materials must meet electrical, mechanical, and environmental requirements.

5. Testing and Validation

Connectors undergo rigorous testing to ensure they meet the specified performance criteria. This includes electrical testing, environmental testing (e.g., temperature, humidity, vibration), and mechanical testing.

6. Production

Once the design is finalized and validated, production begins. Custom connectors can be manufactured in small to large quantities, depending on the application’s needs.

7. Quality Control

Quality control processes are in place throughout production to maintain consistency and reliability. Connectors are inspected for defects, tolerances, and performance.

8. Documentation and Compliance

Comprehensive documentation, including datasheets and compliance certifications, is prepared to ensure that the connector meets industry standards and regulations.

9. Support and Maintenance

Manufacturers often provide ongoing support and maintenance to address any issues that may arise during the connector’s lifecycle.

Manufacturers & Supplier of 24 Pin Connector

Here are some reputable manufacturers and suppliers of 24 pin connectors are –

- TE Connectivity: TE Connectivity is a global leader in connector technology and offers a wide range of connectors, including 24-pin connectors, for various industries.

- Molex: Molex is a well-known manufacturer of electronic connectors, and they provide a diverse selection of connectors, including those with 24 pins.

- Amphenol: Amphenol manufactures a broad spectrum of connectors, including 24 pin connectors, designed for applications in aerospace, automotive, industrial, and more.

- Hirose Electric: Hirose Electric specializes in connectors and offers a variety of high-quality 24 pin connectors for different applications, including consumer electronics and automotive.

- Harting: Harting is a global supplier of industrial connectors, and they offer a range of 24 pin connectors suitable for industrial automation and machinery.

- Phoenix Contact: Phoenix Contact is known for its industrial connectivity solutions, and they provide 24-pin connectors for use in automation, electronics, and control applications. I have some emotional attachment with this manufacturer as I had worked in this group as a Mould Engineer.

- Amphenol ICC: A division of Amphenol Corporation, Amphenol ICC focuses on high-performance connectors, including 24-pin connectors, for telecommunications, data centers, and more.

- Lemo: Lemo specializes in precision connectors for challenging environments, and they offer 24 pin connectors with a focus on quality and reliability.

- CUI Devices: CUI Devices provides a range of electronic components, including 24 pin connectors, suitable for various applications in the electronics industry.

- Binder USA: Binder USA is a supplier of circular connectors and provides a selection of 24 pin connectors suitable for industrial and automation applications.

- ITT Cannon: ITT Cannon is a manufacturer of electrical connectors, and they offer a variety of connectors, including 24-pin connectors, for aerospace, defense, and industrial applications.

- Switchcraft: Switchcraft is known for its audio, video, and data connectors, and they offer 24 pin connectors for use in audio-visual and industrial equipment.

- Lumberg Automation: Lumberg Automation specializes in connectors and connectivity solutions for industrial automation, including 24 pin connectors.

- Weidmuller: Weidmuller provides connectivity solutions, including 24 pin connectors, for industrial applications in fields such as energy, transportation, and machinery.

- Souriau: Souriau, a part of Esterline Connection Technologies, offers a range of connectors, including 24 pin connectors, for aerospace, defense, and industrial applications.

Please note that the availability of specific connectors may vary by region and application, so it’s advisable to contact these manufacturers directly or visit their websites for the most up-to-date information on their product offerings and distributors.

Conclusion

Custom 24-pin connectors represent a crucial link in the world of specialized applications and custom designs. Their adaptability, reliability, and performance make them an indispensable component in industries that demand tailored solutions for connectivity challenges. As technology advances and applications become increasingly specialized, custom connectors will continue to play a vital role in powering the innovations of tomorrow. With careful design, rigorous testing, and a commitment to meeting specific requirements, custom 24-pin connectors will remain at the forefront of cutting-edge electrical and electronic engineering.

FAQ’s

What is 24 Pin connector power supply?

A 24-pin connector power supply, commonly known as an ATX power supply, is a crucial component in a desktop computer. It provides electrical power to the various components of the computer, ensuring its proper functioning. Here’s a brief explanation –

1. Power Distribution: The 24-pin connector power supply distributes electrical power to the motherboard and other components of a desktop computer, including the CPU, memory, storage devices, and expansion cards.

2. ATX Standard: It follows the ATX (Advanced Technology Extended) standard, which specifies the design and electrical characteristics of the power supply, ensuring compatibility with most modern motherboards.

3. 24 Pins: The connector has 24 pins, with a detachable 4-pin section, making it backward compatible with older 20-pin connectors. These pins supply different voltages (e.g., +3.3V, +5V, +12V) required by the motherboard and components.

4. Stability and Efficiency: 24-pin power supplies offer stable voltage outputs and high efficiency, ensuring reliable and energy-efficient operation of the computer.

5. Safety Features: They often include safety features like over-voltage protection, over-current protection, and short-circuit protection to safeguard the computer’s components.

6. Compatibility: 24-pin power supplies are compatible with a wide range of motherboards, making them suitable for most desktop computer builds.

How do you push 24 Pin Connector?

Pushing a 24-pin connector into its corresponding socket on a motherboard or other device is a straightforward process.

1. Identify the Connector: Locate the 24-pin connector on your power supply cable. It typically has a single, large rectangular block with 24 pins in a specific arrangement.

2. Align the Notches: Ensure that the connector is oriented correctly by aligning the notches or notched corners on the connector with the corresponding features on the motherboard’s 24-pin socket. This ensures a proper fit and prevents misalignment.

3. Apply Even Pressure: With the connector aligned, gently but firmly push it straight down onto the socket. Be careful not to use excessive force, as the pins are delicate and can bend if mishandled.

4. Listen for a Click: As you push the connector onto the socket, you may hear a satisfying click sound. This click indicates that the connector has been securely locked into place.

5. Verify Secure Connection: After pushing the connector onto the socket, double-check that it is firmly seated. There should be no visible gaps, and it should be snugly attached to the motherboard.

6. Connect the Additional 4-Pin Section: Some 24-pin connectors have a detachable 4-pin section. If your motherboard requires it, attach this section by aligning the pins and gently pushing it into the corresponding socket on the motherboard.

7. Cable Management: Once the connector is securely attached, manage the power supply cables to ensure they do not obstruct airflow or interfere with other components in the computer case.

What is the Male & Female Connector?

Male and female connectors are types of electrical or mechanical connectors used to establish a secure and functional connection between two devices or components. Here’s a short explanation of each –

Male Connector:

A male connector is characterized by protruding pins, plugs, or prongs that are designed to fit into a corresponding female connector.

It is often considered the “inserting” or “plugging” part of the connection.

Male connectors are typically found on cables or devices that need to be inserted into or connected with a female receptacle.

Female Connector:

A female connector, on the other hand, features openings or receptacles designed to accept the pins, plugs, or prongs of a male connector.

It is often considered the “receiving” or “socket” part of the connection.

Female connectors are usually found on devices or components where connections are made, such as on a motherboard or the power supply socket of an electronic device.