Understanding Omron Limit Switches in Injection Molding

Omron limit switches are vital components in injection molding. They detect physical position changes in machine parts, ensuring proper mold closure, and ejection, and safeguarding against errors. By promptly sending signals, they enhance precision, minimize defects, and optimize production processes, ultimately improving the quality and efficiency of injection molding operations.

Factors Influencing Omron Limit Switch Selection

Environmental Conditions

Environmental conditions refer to the external factors that can impact the performance and longevity of Omron limit switches. These include temperature, humidity, dust, dirt, chemicals, and vibration. Extreme temperatures, high humidity, corrosive substances, or mechanical stress can affect the switch’s materials, electronics, and overall functionality. Selecting a switch designed to withstand these conditions is crucial for maintaining reliable operation in various industrial settings.

Positioning Accuracy

Positioning accuracy refers to the ability of a system or device, such as an Omron limit switch, to consistently and precisely detect and indicate the correct position of an object or component. It is a measure of how closely the actual position matches the intended or desired position. High positioning accuracy ensures that movements or processes are controlled with minimal deviation, reducing errors and improving overall system performance and product quality.

Contact Configuration

Contact configuration refers to the arrangement of electrical contacts within a switch. It determines how the switch responds to input or movement. Common configurations include “normally open” (NO), where contacts are not connected in their resting state but close when activated, and “normally closed” (NC), where contacts are connected by default and open when activated. Dual-contact configurations combine both NO and NC contacts in a single switch. The choice of contact configuration depends on the desired behavior for a specific application.

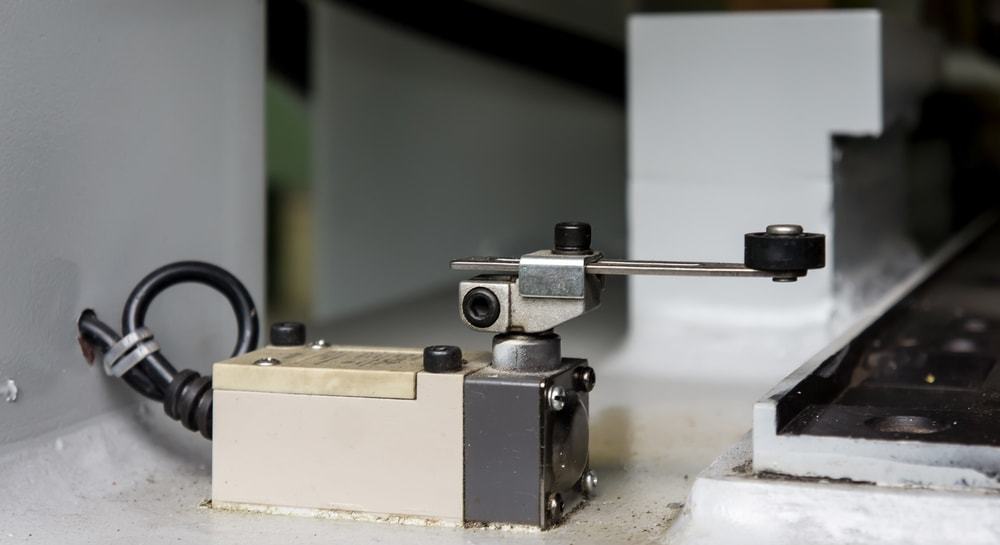

Actuator Types

Actuator types in Omron limit switches define how the switch is activated or triggered by mechanical movement.

- Lever actuators use a lever arm to press the switch when an object moves it.

- Plunger actuators involve a push-button-like mechanism that’s directly depressed.

- Roller actuators use a rotating wheel or cylinder to activate the switch as objects roll against it.

Each type suits different applications based on the nature of movement and the required activation method.

Durability and Longevity

Durability and longevity refer to the ability of an Omron limit switch to withstand prolonged and often harsh operational conditions without deteriorating performance. A durable switch maintains its accuracy, responsiveness, and structural integrity over time. Longevity indicates how long the switch can reliably function before needing replacement. Robust construction, quality materials, and resistance to wear, environmental factors, and mechanical stress contribute to a switch’s durability and extended lifespan.

Wiring and Installation

Wiring and installation involve the process of connecting Omron limit switches into a system. Wiring includes connecting the switch’s electrical terminals to appropriate power sources and control circuits, ensuring compatibility with voltage and current requirements. Installation encompasses physically mounting the switch in a suitable location and aligning the actuator with moving parts for precise detection. Proper wiring and installation are crucial for the switch to function accurately and reliably within the larger industrial setup.

Omron Limit Switch Solutions for Injection Molding

Omron offers tailored limit switch solutions that enhance injection molding processes. Their switches, designed for rugged environments, ensure accurate mold positioning, ejection, and clamp force control. With options like lever, roller, and plunger actuators, they accommodate diverse movements. Advanced materials provide durability against temperature, chemicals, and wear. Precise contact configurations and positioning accuracy reduce defects. Omron’s limit switches optimize injection molding efficiency, quality, and overall productivity.

Case Studies: Real-World Applications

The real-world case studies showcase the versatility and importance of Omron limit switches across various industries, where they contribute to improved accuracy, efficiency, safety, and overall operational excellence.

1. Automated Packaging Line

In a packaging facility, Omron limit switches are used to accurately detect the position of moving conveyor belts and packaging materials. They ensure that products are placed in the correct positions for labeling, sealing, and packaging. The switches’ durability and high accuracy contribute to efficient and error-free packaging processes.

2. Industrial Robots

Omron limit switches play a vital role in industrial robot arms. They help robots accurately determine the position of their joints and end-effectors, ensuring precise movement and placement of objects in manufacturing and assembly lines. This level of accuracy leads to improved product quality and reduced cycle times.

3. Elevator Control

In elevator systems, Omron limit switches are used to accurately detect the position of the elevator car and the doors. They ensure that the doors open and close at the right floors, preventing accidents and ensuring smooth passenger movement.

4. Material Handling Conveyor System

Omron limit switches are employed in material handling systems to detect the presence and position of materials on conveyor belts. This allows for automated sorting, routing, and packaging of items, streamlining logistics and warehouse operations.

5. Automotive Assembly Line

In automotive manufacturing, Omron limit switches are integrated into assembly line equipment. They verify the correct positioning of car components during assembly, contributing to the overall quality and safety of the vehicles being produced.

6. Printing Presses

Omron limit switches are used in printing presses to precisely detect the position of paper rolls and guide rollers. This ensures accurate alignment and tension control, leading to high-quality printing and minimal material waste.

7. Food and Beverage Production

Omron limit switches are employed in food and beverage production lines to detect the presence of containers, bottles, or packages. They enable accurate filling, capping, and labeling processes, maintaining product consistency and packaging integrity.

8. CNC Machining

In computer numerical control (CNC) machines, Omron limit switches determine the limits of movement for cutting tools and workpieces. They prevent collisions and ensure that machining operations stay within specified boundaries, contributing to efficient and precise manufacturing.

Selecting the Perfect Omron Limit Switch

Selecting the perfect Omron limit switch involves considering several key points to ensure the switch meets the specific requirements of your application. Here’s a step-by-step guide –

- Define Application Requirements: Clearly understand the purpose and type of detection needed.

- Environmental Conditions: Choose a switch that can withstand the environment where it will be used.

- Contact Configuration: Decide how the switch’s contacts should behave when activated.

- Actuator Type: Select the actuator that matches the movement needing detection.

- Positioning Accuracy: Determine the level of precision required for accurate detection.

- Load Capacity: Pick a switch that can handle the mechanical load without failing.

- Electrical Specifications: Ensure the switch’s electrical ratings match your system.

- Mounting and Installation: Consider how and where the switch will be mounted.

- Durability and Longevity: Choose a switch with materials and construction that ensure a long operating life.

- Integration and Compatibility: Verify if the switch can work smoothly with your existing setup.

- Budget Considerations: Balance the cost of the switch with its features and benefits.

- Consult Omron Resources: Use Omron’s technical information and support to make informed decisions.

- Trial and Testing: Test the chosen switch in your application to validate its performance.

- Purchase and Implementation: Once satisfied, acquire and incorporate the selected switch into your system.

Conclusion

Omron limit switches stand as indispensable components across various industries, contributing to enhanced precision, safety, and efficiency in countless applications. Their ability to accurately detect positions, movements, and limits ensures seamless automation and control. With diverse actuator types, contact configurations, and robust designs, Omron limit switches cater to a wide range of operational needs. By carefully considering factors like environmental conditions, load capacity, and positioning accuracy, businesses can harness the full potential of these switches to elevate their processes and achieve superior product quality. Omron’s commitment to innovation and reliability further solidifies its position as a trusted choice for optimizing industrial operations through advanced limit switch solutions.

Disclaimer

Before purchasing or using Omron limit switches, it is essential to carefully review and understand the following disclaimer –

- Product Knowledge: Ensure a thorough understanding of the specific Omron limit switch product you intend to purchase or use. Familiarize yourself with its technical specifications, features, and recommended applications.

- Application Compatibility: Verify that the chosen limit switch is compatible with your intended application. Different switches are designed for various environments, load capacities, and functions. Select the appropriate switch that aligns with your operational requirements.

- Installation and Wiring: Proper installation and wiring are critical for optimal switch performance. Follow the manufacturer’s guidelines, wiring diagrams, and installation instructions provided in the product documentation.

- Testing and Verification: Prior to full-scale implementation, consider conducting tests with a sample switch in your application environment. Verify that the switch’s performance meets your expectations and requirements.

- Environmental Considerations: Take into account the environmental conditions in which the limit switch will operate, such as temperature, humidity, and exposure to chemicals. Ensure that the chosen switch is designed to withstand these conditions.

- Safety Precautions: When dealing with electrical components, adhere to safety standards and guidelines. Disconnect power sources and follow best practices to avoid electrical hazards during installation and maintenance.

- Consultation and Expertise: If you are uncertain about any aspect of selecting, installing, or using Omron limit switches, seek advice from qualified professionals or Omron’s technical support team.

- Liability and Warranty: Omron’s liability is limited to the terms outlined in its warranty policy. Any improper installation, misuse, or deviation from recommended usage may void the warranty.

By acknowledging and adhering to this disclaimer, you can ensure a well-informed and safe utilization of Omron limit switches, maximizing their benefits and contributing to the success of your application

FAQ’s

What is Limit Switch in mold?

A limit switch in mold is a mechanical device used in injection molding machines. It detects the position of mold components like closures and ejectors, ensuring accurate alignment and preventing errors. This enhances production quality by enabling precise mold movements and safeguarding against misalignments during the manufacturing process.

What is the function of a Limit Switch?

A limit switch serves to detect the presence, absence, position, or movement of an object in an automated system. When the object reaches a specified point, the switch triggers an electrical signal to control various processes, such as stopping a motor, changing directions, or initiating an action. It ensures accurate control, safety, and efficient automation in industrial applications.

What are the main two types of Limit Switch?

The main two types of limit switches are “normally open” (NO) and “normally closed” (NC). In a normally open switch, the contacts are not connected in their resting state and close when activated. In a normally closed switch, the contacts are connected in their resting state and open when activated. These configurations determine the behavior of the switch when an object or movement reaches the specified point of detection.

What is Mold Limit Switch Price range?

The price range for mold limit switches can vary widely based on factors like brand, features, specifications, and quantity purchased. In India, the price range for basic limit switches could start from around INR 500 to INR 2000 or more, per unit.

Please note that the prices may have changed since this composition published.. For the most accurate and up-to-date pricing information, I recommend contacting specific manufacturers or distributors directly. Here are ten manufacturers of industrial automation components, including limit switches, in India –

1. Omron India

2. Schneider Electric India

3. ABB India

4. L&T Switchgear

5. Honeywell Automation India

6. Siemens India

7. Banner Engineering India

8. Autonics India

9. Yaskawa India

10. Pepperl+Fuchs India

Remember that prices can fluctuate, and it’s always recommended to get in touch with these manufacturers or their authorized distributors to obtain the most accurate and current pricing information.

Top 10 suppliers of mold limit switch in India.

Here are ten manufacturers of industrial automation components, including limit switches, in India –

1. Omron India

2. Schneider Electric India

3. ABB India

4. L&T Switchgear

5. Honeywell Automation India

6. Siemens India

7. Banner Engineering India

8. Autonics India

9. Yaskawa India

10. Pepperl+Fuchs India