Introduction to Die Springs

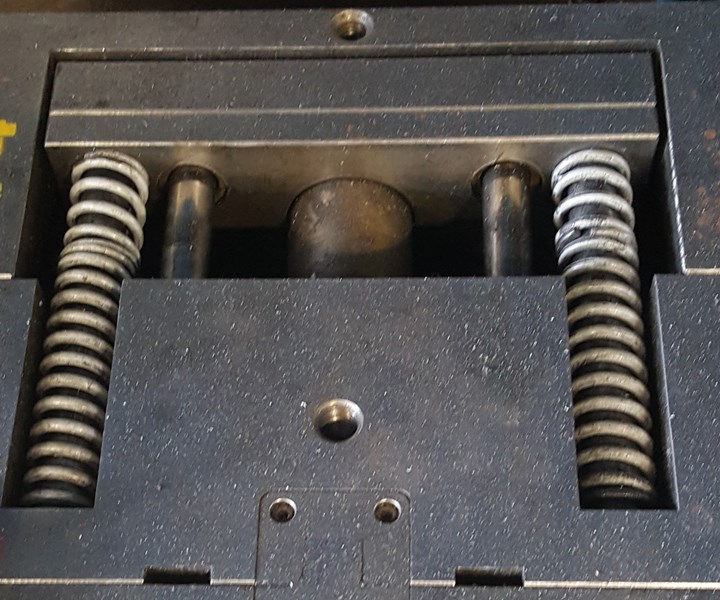

Die springs, also known as heavy-duty compression springs, are mechanical components used to apply force and maintain pressure in various applications. They are commonly found in tool and die systems, where precision and reliability are crucial. Die springs are known for their ability to withstand high loads while providing consistent and predictable force throughout their operational life.

Types of Die/Mould Springs

Die or mold springs are specialized springs used in the field of metalworking and injection molding. They help maintain proper positioning, prevent damage, and absorb shocks in the die or mold machinery. Here’s an explanation of the types of die/mold springs step by step –

- Incorporate a ball plunger mechanism.

- Used to eject parts from molds.

- Provide controlled ejection force.

- Prevent damage to both mold and parts.

2. Dowel Pin Springs:

- Equipped with dowel pins for precise alignment.

- Ensure accurate assembly of mold components.

- Absorb lateral forces and prevent misalignment.

3. Guide Pin Springs:

- Feature guide pins to assist in mold alignment.

- Prevent lateral movement and ensure accurate mating.

- Help extend the life of mold components.

- Utilize compressed nitrogen gas for force generation.

- Offer consistent force over a long stroke.

- Used for mold opening, closing, and ejector systems.

5. Polyurethane Springs:

- Made from polyurethane material.

- Absorb shock and vibration during mold operation.

- Suitable for minimizing noise and enhancing mold life.

6. Round Wire Springs:

- A common type of die/mold spring.

- Made from round wire.

- Offer various load capacities and sizes.

- Used for general applications in molds and dies.

7. Heavy-Duty Springs:

- Engineered for heavy-duty applications.

- Withstand high loads and stress.

- Suitable for large molds or dies with substantial forces.

8. Urethane Springs:

- Constructed from urethane material.

- Provide elasticity and shock absorption.

- Used to reduce impact and protect molds.

9. ISO Standard Springs:

- Follow ISO 10243 standard for die/mold springs.

- Characterized by color codes indicating force levels.

- Ensure consistency and interchangeability.

10. JIS Standard Springs:

- Comply with Japanese Industrial Standard (JIS B5012).

- Similar to ISO standards but with JIS specifications.

- Commonly used in regions following JIS standards.

11. Tapered Springs:

- Conical shape with varying diameters along the length.

- Offer progressive force throughout compression.

- Used for applications needing controlled force distribution.

Choosing the appropriate type of die/mold spring depends on factors such as the specific application, load requirements, alignment needs, and desired level of shock absorption. These springs play a crucial role in ensuring the smooth and efficient operation of die and mold machinery.

Best Practices for Die Springs Applications

Best practices for die spring applications are essential to ensure optimal performance, longevity, and safety. Here’s a step-wise overview –

- Selecting the Right Spring:

- Identify the load requirements, deflection range, and working conditions of the application.

- Choose the appropriate die spring size, type, and load capacity based on the calculated needs.

- Consider the spring’s material, as different materials offer varying levels of durability and resistance to corrosion.

- Proper Installation:

- Follow manufacturer guidelines for correct installation, including proper orientation and alignment of the spring.

- Ensure the spring is securely mounted and doesn’t experience lateral or side loads.

- Use appropriate tools and techniques to prevent damage to the spring during installation.

- Regular Maintenance:

- Establish a maintenance schedule to inspect and maintain die springs periodically.

- Check for signs of wear, fatigue, or damage, such as cracks, distortion, or loss of load capacity.

- Replace worn or damaged springs promptly to prevent disruptions in production and ensure safety.

- Lubrication:

- Apply a suitable lubricant to the spring’s surfaces to reduce friction and wear.

- Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants to use.

- Avoid Overloading:

- Do not exceed the recommended load capacity of the die spring to prevent premature failure or deformation.

- Choose a spring with a load rating that provides a safety margin to account for dynamic loading and variations in operating conditions.

- Controlled Environment:

- Maintain a controlled environment that aligns with the recommended temperature and humidity conditions for the specific spring material.

- Protect the springs from exposure to corrosive chemicals or abrasive particles that could degrade their performance.

- Safety Precautions:

- Implement safety measures to prevent accidents during the installation, maintenance, and operation of die springs.

- Use proper personal protective equipment (PPE) when handling springs or working around machinery.

- Regular Inspection:

- Incorporate die spring inspection as part of routine maintenance procedures.

- Inspect springs for signs of wear, fatigue, or damage, and address any issues immediately.

- Record Keeping:

- Maintain accurate records of spring installations, replacements, and maintenance activities.

- Keep track of the operating conditions, loads, and any issues encountered.

- Consult Manufacturer Guidelines:

- Refer to the manufacturer’s recommendations, guidelines, and technical documentation for specific information on spring selection, installation, and maintenance.

- Training and Education:

- Provide training to personnel responsible for working with die springs, ensuring they understand the proper procedures and safety protocols.

By following these best practices, industries can maximize the performance, reliability, and service life of die springs while minimizing downtime and potential safety risks.

How to Choosing the Right Die Springs

Choosing the right die springs involves a systematic approach to match the spring’s characteristics with the specific application requirements. Here’s a step-wise guide –

- Identify Application Requirements:

- Determine the load that the spring needs to support. Consider both static and dynamic loads.

- Define the required deflection or travel distance the spring must accommodate.

- Understand the working environment, including temperature, humidity, and exposure to chemicals or contaminants.

- Calculate Spring Specifications:

- Use the load and deflection requirements to calculate the spring’s required force rate (load per unit of deflection) in units like N/mm or lbs/in.

- Calculate the spring’s estimated working height to ensure it fits within the available space.

- Choose Spring Type and Material:

- Select the appropriate type of die spring based on the application’s needs. There are various types, including rectangular, cylindrical, and conical.

- Choose a spring material that suits the application’s requirements. Chrome silicon and chrome vanadium steel are common choices due to their durability and resistance to fatigue.

- Consult Load-Deflection Curves:

- Manufacturers often provide load-deflection curves for their springs. These curves help you understand how the spring’s force changes as it deflects.

- Use the load-deflection curve to ensure the selected spring meets both the load and deflection requirements of the application.

- Consider Safety Factors:

- Incorporate a safety factor to ensure the spring can handle variations in load, shock loads, and potential wear over time.

- Generally, a safety factor of around 1.2 to 1.5 is recommended to account for uncertainties in the application.

- Account for Spring Life Expectancy:

- Calculate the expected number of cycles the spring will endure over its service life.

- Consider the spring’s endurance limit and expected fatigue life under the application’s conditions.

- Match Spring Color Code:

- Many manufacturers use color codes to differentiate springs based on load capacity. Ensure you choose springs with the appropriate color code that aligns with your load requirements.

- Verify Spring Dimensions:

- Check the spring’s physical dimensions, such as outer diameter, inner diameter, and free length, to ensure it fits within the available space and mounting configuration.

- Review Manufacturer’s Documentation:

- Refer to the manufacturer’s catalog or technical documentation for detailed information about the selected spring’s specifications, load capacities, and other relevant data.

- Consult with Experts:

- If in doubt, consult with engineers or experts familiar with die spring applications.

- Manufacturers’ technical support teams can also provide guidance in selecting the right spring for your specific needs.

- Test and Validate:

- If possible, perform testing or simulations to validate the chosen spring’s performance under actual operating conditions before full-scale implementation.

By following these steps, you can make an informed decision when selecting die springs that will meet your application’s requirements for load capacity, deflection, durability, and overall performance.

Die Spring Applications in Various Industries

Die springs find applications across a range of industries due to their unique properties and capabilities –

- Metal Stamping Industry:

- Die springs are used in stamping presses to provide the required force for shaping and forming metal sheets.

- They ensure consistent pressure during the stamping process, resulting in accurate and precise metal components.

- Die springs enable high-speed stamping operations while maintaining reliability and longevity.

- Plastic Injection Molding Industry:

- Die springs are employed in injection molding machines to apply the necessary force to hold the mold’s components together during the plastic injection process.

- They ensure proper alignment and prevent flashing or defects in the molded plastic parts.

- Die springs withstand the high pressure and repetitive cycles of the injection molding process.

- Automotive Industry:

- Die springs are used in automotive manufacturing for tasks such as forming, cutting, and bending metal components.

- They contribute to the production of vehicle parts like body panels, brackets, and structural components.

- Die springs’ high load capacity and reliability support the demanding requirements of automotive assembly lines.

- Aerospace Industry:

- Die springs are employed in aerospace applications for tasks like sheet metal forming, precision machining, and assembly.

- They ensure the accurate fabrication of aircraft components, ranging from engine parts to interior fittings.

- Die springs’ durability and resistance to harsh environments suit the stringent demands of aerospace manufacturing.

- Tool and Die Industry:

- Die springs play a pivotal role in tool and die-making, supporting processes like shearing, cutting, and bending metal sheets.

- They maintain consistent pressure in dies, resulting in the production of intricate and accurate tooling components.

- Die springs’ long operating life and customizable options align with the diverse needs of tool and die applications.

- Packaging Industry:

- Die springs are used in packaging machinery for tasks like cutting, sealing, and forming packaging materials.

- They contribute to the efficient and reliable operation of packaging lines, ensuring precise package dimensions and quality.

- Die springs’ ability to handle high-speed operations and maintain performance is vital in the fast-paced packaging sector.

- Electronics Industry:

- Die springs find use in electronics manufacturing for precision cutting, forming, and assembly of electronic components.

- They contribute to the production of circuit boards, connectors, and casings with high accuracy and consistency.

- Die springs’ ability to provide controlled force aids in delicate electronic component handling.

- Medical Device Industry:

- Die springs are employed in medical device manufacturing for tasks like precision cutting, shaping, and forming of medical instruments and components.

- They contribute to the production of implants, surgical instruments, and medical equipment.

- Die springs’ reliability and consistent performance meet the stringent quality requirements of the medical field.

Advantages of Using Die Springs

Die springs offer several advantages when used in various applications –

- High Load Capacity: Die springs are specifically designed to handle heavy loads, making them ideal for applications where substantial force is required, such as in metal stamping, die-cutting, and plastic injection molding.

- Long Operating Life: Die springs are made from high-quality materials, usually chrome silicon or chrome vanadium steel, which provide excellent durability and resistance to fatigue. This results in a longer operating life compared to other types of springs.

- Consistent Performance: Die springs maintain their performance characteristics over long periods of use, offering consistent force and deflection values throughout their lifespan. This predictability is crucial in applications where precision is essential.

- High Deflection Range: Die springs can withstand a significant amount of deflection without compromising their performance, making them suitable for applications with varying height requirements or where space constraints exist.

- Wide Range of Sizes and Load Options: Die springs are available in a wide range of sizes, diameters, and load capacities. This versatility allows engineers to choose the appropriate spring for their specific application needs.

- Resistance to Harsh Environments: Die springs are designed to withstand challenging working conditions, including high temperatures, corrosive environments, and exposure to various chemicals. This makes them suitable for use in industries such as automotive, aerospace, and manufacturing.

- Quick Installation and Replacement: Die springs can be easily installed and replaced, minimizing downtime during maintenance or repairs. This is essential in industries that rely heavily on continuous production processes.

- Cost-Effective: Due to their durability and long operating life, die springs often provide a cost-effective solution in the long run. They reduce the need for frequent replacements, leading to lower maintenance and operational costs.

- Reliable Performance at High Speeds: Die springs can operate effectively at high speeds without compromising their performance characteristics, making them suitable for high-speed stamping and forming applications.

- Customization Options: Die springs can be customized to meet specific load and size requirements, allowing engineers to tailor the spring’s characteristics to the needs of the application.

Case Studies: Real-World Die Spring Implementations

Examining real-world scenarios highlights the significance of die springs. In a high-volume stamping operation, properly selected die springs reduced wear on tools and increased production output. In precision injection molding, die springs maintained pressure on molds, resulting in defect-free products and reduced cycle times.

Future Trends and Innovations

As technology advances, die springs continue to evolve. Innovations include new materials with enhanced durability and corrosion resistance, as well as advanced spring design techniques to optimize force distribution and efficiency.

Conclusion

Die springs are foundational components in industries reliant on precision, efficiency, and reliability. By understanding their types, selecting appropriate springs, and implementing best practices, manufacturers can ensure the consistent and effective operation of their industrial processes. Die springs contribute to improved product quality, reduced downtime, and enhanced overall productivity across diverse sectors.

FAQ’s

What are Die Springs made of?

Die springs are typically made from high-quality spring steel materials that offer a balance of strength, durability, and resistance to fatigue. The most common materials used for manufacturing die springs are –

1. Chrome Silicon Steel (CrSi):

Chrome silicon steel is a popular choice for die springs due to its excellent combination of strength, toughness, and resistance to high temperatures.

It offers good corrosion resistance and maintains its performance characteristics even in harsh environments.

Die springs made from chrome silicon steel can handle heavy loads and provide reliable deflection over extended periods.

2. Chrome Vanadium Steel (CrV):

Chrome vanadium steel is another widely used material for die springs.

It offers similar properties to chrome silicon steel, including high strength, durability, and resistance to fatigue.

Chrome vanadium steel die springs are suitable for demanding applications where consistent force and long service life are essential.

These materials are chosen for die springs because they can withstand the high stresses and repetitive loading that occur in applications like metal stamping, plastic injection molding, and other heavy-duty industrial processes. The specific material chosen depends on factors such as the application’s operating conditions, load requirements, and expected service life.

Is a Die Springs a Compression Springs

Yes, a die spring is a type of compression spring. Compression springs are designed to resist compression or pushing forces, and they store energy when compressed and release it when the load is removed. Die springs are a specific subset of compression springs designed to handle heavy loads and provide consistent, predictable force over a long lifespan. They are commonly used in applications where high forces are required, such as metal stamping, plastic injection molding, and other industrial processes. Die springs are characterized by their rectangular or cylindrical shape and are typically made from materials that offer durability and resistance to fatigue, such as chrome silicon or chrome vanadium steel.

What is the use of the Springs Color Chart? Explain in detail.

The spring color chart, often referred to as the “spring color code,” is a standardized system used to visually differentiate between different types and load capacities of springs, including die springs. It provides a quick and convenient way to identify and select the right spring for a specific application without needing to refer to detailed specifications. The color chart assigns specific colors to various load ranges, making it easier for engineers, technicians, and operators to choose the appropriate spring for their needs. Here’s a detailed explanation of its use –

1. Load Identification:

Each color on the chart corresponds to a specific load range or load capacity for a given type of spring.

Springs are grouped into load categories, and each category is assigned a unique color.

The chart helps users quickly identify which springs are suitable for different load requirements.

2. Visual Differentiation:

The color code eliminates the need to measure or read load specifications directly from the spring, which can be time-consuming and prone to errors.

Operators and maintenance personnel can identify springs by their color, streamlining the installation, replacement, and maintenance processes.

3. Quick Selection:

When selecting a spring for an application, engineers can refer to the color chart to narrow down their options based on the load requirements.

This speeds up the decision-making process and ensures that the correct spring is chosen on the first attempt.

4. Reduces Errors:

Using the color chart reduces the chances of selecting the wrong spring due to confusion or misinterpretation of load specifications.

This helps prevent costly errors and potential safety hazards caused by using an incorrect spring.

5. Consistency and Standardization:

The color chart provides a consistent and standardized method of identifying springs across different industries and manufacturers.

It ensures that personnel are using a common reference, even when working with springs from various sources.

6. Training and Accessibility:

The color code simplifies the training process for new personnel who may not be familiar with detailed spring specifications.

It also makes spring selection accessible to individuals who may not have advanced technical knowledge.

7. Quick Replacement:

In maintenance and repair scenarios, where quick replacement is essential, the color chart enables operators to easily find the correct replacement spring based on the existing color code.

8. Inventory Management:

Companies with a large inventory of springs can efficiently organize and manage their stock using the color code system, reducing confusion and errors.

9. Compatibility Assurance:

The color chart ensures that the selected spring is compatible with the intended application’s load requirements, leading to improved performance and longevity.

10. Application Flexibility:

Users can quickly adapt to changing load requirements by referencing the color chart and selecting springs that match their new needs.

What is Urethane Die Springs?

Urethane die springs, also known as urethane compression springs or polyurethane springs, are a type of non-metallic spring used in various industrial applications. Unlike traditional metal springs, urethane die springs are made from polyurethane, a versatile polymer material. Here’s a brief explanation –

Composition: Urethane die springs are constructed from polyurethane, a synthetic polymer that exhibits elastic behavior when subjected to compression. Polyurethane is known for its durability, resilience, and resistance to abrasion, chemicals, and impacts.

Properties: Urethane die springs offer several unique properties:

Non-metallic: Urethane springs provide an alternative to traditional metal springs, which can be advantageous in certain applications.

High Load Capacity: Despite being non-metallic, urethane springs can handle substantial loads and provide effective compression characteristics.

Noise and Vibration Damping: Urethane’s elastomeric nature allows it to absorb and dampen vibrations and shocks, making it suitable for applications where noise reduction is important.

Chemical Resistance: Urethane springs are resistant to various chemicals and solvents, making them suitable for industries where exposure to such substances is common.

Applications: Urethane die springs find applications in diverse industries:

Stamping and Forming: Urethane springs can be used in metal stamping and forming processes where they provide cushioning and absorb energy during impact.

Presses and Machinery: They are used in hydraulic and mechanical presses to control impact forces and minimize noise.

Automation and Robotics: Urethane springs are employed to dampen vibrations and shocks in automation and robotics systems.

Materials Handling: These springs can be used in conveyors and material handling equipment to provide smooth transitions and reduce impacts.

Advantages:

Urethane die springs’ non-metallic nature can be advantageous in applications where avoiding metal-on-metal contact is important.

They offer noise reduction and shock absorption benefits.

Urethane springs’ chemical resistance makes them suitable for industries where exposure to harsh substances is common.

They can provide customization options in terms of hardness and geometry to suit specific application requirements.

Considerations:

Urethane springs may have different load-deflection characteristics compared to traditional metal springs, so careful selection and testing are important.

The operating temperature range of urethane springs might be more limited compared to some metal springs.

Explain Die Springs vs. Compression Springs.

Die springs and compression springs are both types of mechanical springs, but they serve distinct purposes and have specific design characteristics that make them suitable for different applications. Here’s a comparison between die springs and compression springs –

1. Purpose and Applications:

Die Springs: Die springs are specifically designed to handle heavy loads and provide consistent, predictable force over a long lifespan. They are commonly used in applications where high forces are required, such as metal stamping, plastic injection molding, and heavy machinery.

Compression Springs: Compression springs are more general-purpose springs used to resist compression forces. They are found in a wide range of applications, including automotive suspension systems, industrial machinery, consumer products, and more.

2. Load and Force:

Die Springs: Die springs are engineered to handle high loads and provide reliable force within a defined load range. They are designed to deliver a specific force at a particular deflection.

Compression Springs: Compression springs come in various load capacities and are available for a wide range of force requirements. They can handle light to moderate loads.

3. Shape and Design:

Die Springs: Die springs often have a rectangular or cylindrical shape with closely spaced coils. This design allows them to handle the high stress and deflection requirements of their intended applications.

Compression Springs: Compression springs have a variety of shapes, including cylindrical, conical, and barrel-shaped. Their design can be more varied to suit different force and space constraints.

4. Material and Durability:

Die Springs: Die springs are typically made from high-quality spring steel materials like chrome silicon or chrome vanadium steel. These materials offer durability, resistance to fatigue, and the ability to handle harsh conditions.

Compression Springs: Compression springs can be made from a wide range of materials, including various types of steel, stainless steel, and non-metallic materials. The material choice depends on factors like load requirements, environmental conditions, and cost considerations.

5. Load-Deflection Characteristics:

Die Springs: Die springs are designed to provide a consistent force across their working range, maintaining a relatively flat load-deflection curve.

Compression Springs: Compression springs may have a more variable load-deflection curve depending on their design, making their force characteristics less predictable compared to die springs.

6. Industry Use:

Die Springs: Die springs are commonly used in industries like manufacturing, metal stamping, plastic injection molding, and heavy equipment where precise force and durability are essential.

Compression Springs: Compression springs are found in a wide range of industries including automotive, aerospace, consumer electronics, medical devices, and more due to their versatility.