The “All-in-One Hot Runner Mold Repair and Troubleshooting Manual” is a complete technical guide for mold makers, engineers, and maintenance experts in the injection molding industry. Covering global practices from the USA, Germany, Japan, China, and India, this article explains every major hot runner problem in detail with practical troubleshooting methods.

Common issues such as heater short, thermocouple short, material leakage, blocked hot runner tips, sequential pin malfunction, unstable or fluctuating zone temperatures, HRTC fuse failure, connector wire burnout, and body touch errors are addressed with their possible causes, step-by-step repair techniques, and preventive measures. The manual also highlights best maintenance practices, industry-specific solutions, and preventive care to reduce downtime, enhance safety, and extend mold life. With real-world insights and 20 frequently asked questions, this comprehensive resource ensures professionals can diagnose, fix, and prevent hot runner problems effectively.

Introduction

In modern plastic injection molding, hot runner molds play a critical role in delivering consistent quality, reducing material waste, and ensuring faster cycle times. Unlike cold runner systems, hot runners keep the plastic material molten inside a heated manifold, delivering it directly into the mold cavities through nozzles and tips. This technology has become standard in automobile, medical, packaging, and consumer industries worldwide, especially in USA, Germany, Japan, China, and India.

However, with these benefits comes complexity. A single fault in the hot runner system can halt production, waste expensive engineering-grade resins, and increase downtime. In the automobile sector, where demand for precision and productivity is extremely high, mold downtime costs can run into thousands of dollars per hour.

This all-in-one troubleshooting manual is designed for mold makers, toolroom engineers, production supervisors, and maintenance teams who face challenges with hot runner systems. The guide provides a practical, step-by-step mindset to diagnose issues, identify root causes, and implement effective solutions.

Common Hot Runner Mold Problems and Their Troubleshooting

Heater Short Circuit

Possible Causes:

- Damage to heater insulation due to overheating

- Moisture absorption when heaters are left idle in humid environments

- Physical damage during installation/removal

- Electrical surge or grounding issues

Troubleshooting:

- Disconnect heater from circuit and check with a multimeter for resistance values.

- Normal range: depends on heater wattage (e.g., 30–100Ω).

- If resistance = 0 → direct short.

- If resistance = ∞ → open circuit.

- Perform megger test for insulation resistance. It should be above 10 MΩ.

- Replace heater if shorted.

- Ensure proper storage in a dry cabinet or use preheating before startup.

- Use ceramic or mineral-insulated heaters for longer life.

Thermocouple Short / Failure

Possible Causes:

- Pinching of wires during mold clamping

- Incorrect bending radius, leading to internal wire breakage

- Temperature cycling causing wear at junction

- Loose fit in manifold bore

Troubleshooting:

- Cross-check zone temperature by swapping thermocouple with a working one.

- Inspect wiring for visible cuts or burnt sections.

- Verify with a multimeter:

- Room temperature should show millivolt range output.

- If no signal = broken junction.

- Replace with correct type (J or K type) as per OEM.

- Ensure thermocouple is seated firmly in the manifold bore.

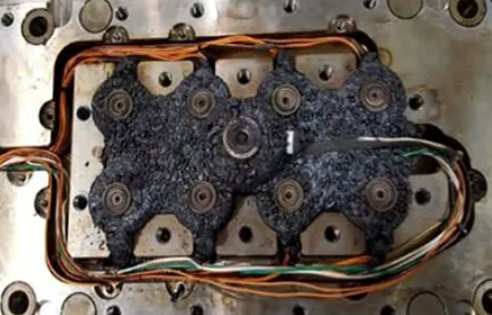

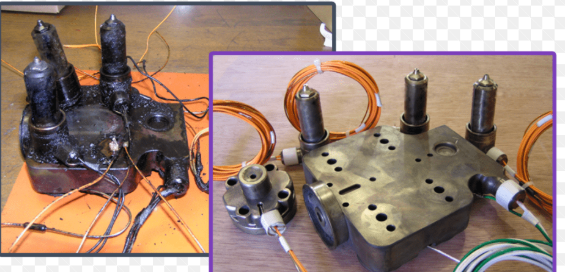

Hot Runner Mold Connector Wire Burnout

Possible Causes:

- Loose terminals causing arcing

- Undersized cables not matching current load

- Overheating from poor ventilation

- Prolonged vibration during machine operation

Troubleshooting:

- Visually check connectors for carbon marks or discoloration.

- Replace burnt cables with high-temperature Teflon/silicone-coated wires.

- Use correct ampere-rated connectors.

- Tighten terminals with torque screwdriver.

- Schedule weekly connector inspections.

Heater or Thermocouple Showing “Body Touch“

Possible Causes:

- Damaged insulation layer allowing live wire to touch manifold

- Moisture penetration inside heater

- Sheath cracks due to mishandling

Troubleshooting:

- Disconnect and perform insulation resistance test (>10 MΩ is safe).

- Replace faulty heaters/thermocouples immediately.

- Always use grounding straps for mold safety.

- Avoid hammering heaters into tight bores; ream the bore properly.

Advanced Hot Runner Mold Problems

Material Leakage in Hot Runner Mold Manifold

Possible Causes:

- Improper bolt torque during assembly

- Damaged O-rings or seals

- Warped manifold plates due to overheating

- Thermal expansion mismatch between manifold and nozzle

Troubleshooting:

- Disassemble mold carefully; clean leaked resin.

- Inspect O-rings/seals for flattening or cuts → replace with OEM spares only.

- Check manifold flatness using feeler gauge.

- Reassemble with calibrated torque wrench.

- Use thermal insulation sheets to control expansion.

Hot Runner Mold Sequential Pin Not Working

Possible Causes:

- Solenoid valve stuck or damaged

- Pneumatic air leakage in pipeline

- Bent or worn valve pin

- PLC program error in sequential controller

Troubleshooting:

- Check air pressure supply (generally 5–6 bar).

- Manually actuate solenoid valve → if not moving, replace.

- Remove and inspect pin for wear or galling.

- Review PLC program sequence and sensor inputs.

- Replace damaged seals in cylinders.

Hot Runner Mold Tip Blocked

Possible Causes:

- Carbon build-up due to overheating

- Contaminated material (dust, moisture, foreign particles)

- Improper purging after shutdown

- Worn tip insert

Troubleshooting:

- Raise mold to purging temperature and flush with cleaning compound.

- If blocked, remove nozzle tip and clean ultrasonically.

- For stubborn carbon, use brass wire brush (never steel).

- Always purge before mold shutdown.

- Replace tip if erosion or wear is visible.

Zone Temperature Instability

Symptoms:

- Temperature not increasing

- Temperature dropping suddenly

- Temperature overshooting

- Controller shows correct setpoint but cavity does not heat

Possible Causes:

- Heater burnout

- Thermocouple drift or misplacement

- Faulty HRTC (Hot Runner Temperature Controller) card

- Electrical grounding or EMI interference

Troubleshooting:

- Swap heater with another zone → if problem shifts, heater is faulty.

- Swap thermocouple → if problem shifts, thermocouple is faulty.

- Inspect controller board for damage; replace fuse/card if required.

- Install EMI filters and ensure proper grounding.

HRTC Fuse Blown

Possible Causes:

- Heater short circuit

- Power surge from supply line

- Wrong fuse rating

Troubleshooting:

- Check heater/thermocouple insulation before replacing fuse.

- Use OEM-specified fuse rating.

- Install surge protector on main supply.

Hot Runner Mold Sequential Control Not Working

Possible Causes:

- Controller communication error

- Broken wiring harness

- Contaminated compressed air supply

Troubleshooting:

- Switch controller to manual mode → check sequential opening.

- Replace broken wires/loose connectors.

- Install air dryer/filters in pneumatic line.

Other Problems and Preventive Measures

- Uneven Cavity Filling: Caused by unbalanced temperature across manifold → solved by balancing zones and using cavity pressure sensors.

- Overheating of Mold Base: Due to poor insulation → solved by adding insulation plates.

- Controller Display Errors: Caused by faulty communication cable or power fluctuation → solved by replacing cable or stabilizer.

- Valve Pin Wear: Caused by abrasive material or misalignment → polish or replace pin, check guide bushing.

Best Practices in Hot Runner Mold Maintenance

- Preventive Maintenance: Schedule PM after every production batch; check heaters, thermocouples, connectors, and pins.

- Global Practices:

- USA → Data-driven predictive maintenance using sensors.

- Germany → Strict torque calibration and dimensional checks.

- Japan → Kaizen continuous improvement with operator training.

- China → High-volume, quick turnaround repairs.

- India → Cost-effective solutions, spares reuse with safety focus.

Safety Guidelines for Hot Runner Mold

- Always disconnect power before opening mold.

- Use insulated screwdrivers and torque tools.

- Verify grounding before resistance checks.

- Wear safety glasses and heat-resistant gloves.

- Follow OEM recommended startup/shutdown sequence.

Conclusion

Hot runner molds are highly efficient but equally sensitive systems. Their reliability depends on proper installation, regular preventive maintenance, and systematic troubleshooting when issues occur. By following the practical steps outlined in this manual, mold engineers and maintenance teams can minimize downtime, extend tool life, and maintain consistent production quality in automobile molding plants across USA, Germany, Japan, China, and India.

FAQ’S

What is the most common failure in hot runner molds?

The most common failure is heater burnout or short circuit. Heaters work under extreme conditions (high temperatures, frequent start/stop cycles, and pressure). Over time, insulation wears out or moisture enters, causing shorts. Preventive maintenance and pre-heating cycles can minimize this.

How to test a heater for short circuit?

Disconnect the heater and check with a multimeter:

- Normal resistance → 30–100Ω depending on wattage.

- If resistance = 0 → short circuit.

- If resistance = ∞ → open circuit.

Also, do a megger test for insulation resistance. It should be above 10 MΩ.

Why does material leak in hot runner manifolds?

Material leakage happens when:

Manifold plates are warped due to overheating.

Solution: Always reassemble with torque wrench, replace O-rings, and check flatness of plates.

- Bolts are not tightened to the correct torque.

- Seals/O-rings are damaged.

How to prevent hot runner mold tip blockage?

- Always purge with cleaning compound before shutdown.

- Avoid overheating the material (prevents carbon buildup).

- Use clean, moisture-free resin.

- Schedule preventive cleaning after every large production batch.

Can a thermocouple be repaired?

Thermocouples are generally not repairable because the junction and insulation are delicate. If wires break or insulation is damaged, readings become unreliable. The safest practice is replacement with OEM-approved thermocouples.

What is “body touch” in heaters?

Body touch” means the live wire inside the heater or thermocouple is in contact with the manifold body, creating a short to ground.

This is dangerous because:

- It can shock the operator.

- It damages the HRTC controller.

Solution → Test insulation resistance, replace faulty part, and ensure proper grounding.

Why does HRTC fuse blow repeatedly?

Fuses blow due to:

- Heater short circuit.

- Wrong fuse rating used.

- Sudden power surge from supply.

Solution → Identify the short, use OEM fuse ratings, and install surge protectors in main line.

How to check if sequential pin is faulty?

- Manually actuate the solenoid valve. If the pin doesn’t move → check for air leakage.

- Measure air pressure (should be 5–6 bar).

- If pin is stuck, remove and check for galling or bending.

- If PLC signal is missing → check controller logic.

What are best practices for hot runner storage?

- Store heaters and thermocouples in a dry cabinet with silica gel.

- Keep connectors covered to avoid dust and moisture.

- Coat exposed metal parts with rust preventive spray.

- Do not stack manifolds directly; always use wooden/plastic supports.

How to balance uneven cavity filling?

- Check nozzle zone temperatures for imbalance.

- Verify heaters and thermocouples are working correctly.

- Use cavity pressure sensors to identify flow difference.

- Adjust process parameters or install flow restrictors in high-flow cavities.

Which industries rely most on hot runner mold systems?

- Automobile (bumpers, dashboards, interior trims)

- Medical (syringes, IV sets, diagnostic components)

- Packaging (caps, closures, bottles)

- Consumer electronics (laptops, phones, TV components)

How often should hot runner connectors be checked?

Connectors should be checked weekly for:

- Loose screws

- Burn marks

- Wire insulation damage

A monthly preventive replacement schedule is ideal in high-volume production.

Why does the controller show correct setpoint but heating fails?

This usually means:

- Thermocouple is giving false feedback (broken junction).

- Heater is not generating heat despite correct resistance.

- Controller card output is faulty.

Solution: Swap heater/thermocouple with a working zone to isolate.

What causes thermocouple drift?

- Continuous heating and cooling cycles

- Loose fitting in manifold bore

- Wrong grade material used

- Oxidation of wires at high temperatures

- Drift leads to false readings → replace if deviation >5°C.

How to prevent heater burnout?

- Use soft start feature in controller (gradual heating).

- Always pre-heat mold at 50% power for 15–20 minutes.

- Avoid moisture by storing heaters in dry place.

- Never hammer heaters into bores; ensure proper fit.

What are global best practices in hot runner mold maintenance?

- USA: Predictive maintenance with sensors and IoT data.

- Germany: Precision torque calibration and strict flatness checks.

- Japan: Kaizen – small continuous improvements and operator discipline.

- China: Quick turnaround repairs for mass production.

- India: Cost-effective repairs with focus on reusing spares safely.

Why do valve pins wear prematurely?

- Abrasive glass-filled material

- Misalignment in guide bush

- Lack of lubrication in pneumatic pins

- Over-pressure injection settings

- Solution → Use coated pins, check alignment, and lubricate regularly.

What safety steps must be followed before repair?

- Disconnect power completely.

- Discharge stored heat safely.

- Wear safety glasses and heat-resistant gloves.

- Verify grounding before resistance testing.

- Follow lockout-tagout (LOTO) procedure.

How to troubleshoot zone temperature fluctuation?

- Swap heater/thermocouple with another zone to confirm fault.

- Check for loose wiring in connectors.

- Verify controller calibration.

- Use EMI filters if electrical noise is suspected.

How to extend heater and thermocouple lifespan?

- Always use OEM parts.

- Preheat before full production load.

- Keep mold and connectors dry.

- Avoid sharp bends in thermocouple wires.

- Perform resistance and insulation checks monthly.

- Thermoplastic Elastomers (TPE) Material Explained: Types, Properties, Applications & Market

- Comprehensive Guide on Thermoplastic Olefin (TPO) Material – Point-to-Point Explanation

- All-in-One Hot Runner Mold Repair and Troubleshooting Manual

- Comprehensive guide on EPDM in Transfer Molding: Definition, Composition, Manufacturing, Shelf Life, Properties, Pros & Cons, Applications, FAQs.

- Mold Preventive Maintenance Checksheet

I must say this article is extremely well written, insightful, and packed with valuable knowledge that shows the author’s deep expertise on the subject, and I truly appreciate the time and effort that has gone into creating such high-quality content because it is not only helpful but also inspiring for readers like me who are always looking for trustworthy resources online. Keep up the good work and write more. i am a follower.

Hey there, You’ve performed a fantastic job. I’ll certainly digg it and individually recommend to my friends. I’m sure they will be benefited from this web site.

I was suggested this web site by my cousin Im not sure whether this post is written by him as no one else know such detailed about my trouble You are incredible Thanks

Hello. Great job. I did not imagine this. This is a great story. Thanks!

Really clear web site, thankyou for this post.

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!

Hello my loved one! I wish to say that this article is amazing, nice written and include approximately all vital infos. I would like to look extra posts like this .

Rattling clean web site, thankyou for this post.