Introduction

Lifting eye bolts are essential hardware used in various industries for material handling and lifting operations. Despite their significance in ensuring safety and efficiency, they are often overlooked or misunderstood. In this comprehensive guide, we will explore the world of lifting eye bolts, understanding their types, applications, safety considerations, and how to choose the right one for your specific lifting needs.

What are Lifting Eye Bolts?

A lifting eye bolt, also known as an eye bolt or lifting eye, is a specialized fastener used in rigging and lifting applications to provide a secure point for attaching rigging hardware. It typically consists of a threaded shank with a circular or looped eyelet at one end. The eyelet is the attachment point for hooks, slings, or other rigging components used to safely lift and move heavy loads.

The design and materials used in lifting eye bolts are carefully chosen to withstand the stresses and forces involved in raising operations. They are available in various types and configurations, each suited for specific applications and load capacities.

Components of a Lifting Eye Bolt

Threaded Shank: The threaded shank forms the body of the lifting eye bolt. It is usually made of high-strength steel or other materials with sufficient load-bearing capacity.

Eyelet: The eyelet is the circular or looped structure at the end of the threaded shank. It provides the attachment point for rigging hardware such as hooks, shackles, or slings.

Material Used in Eye Bolt

Lifting eye bolts are typically made from various materials, each chosen based on load capacity, environment, and application requirements. The choice of material affects the bolt’s strength, corrosion resistance, and overall durability. Some common materials used in manufacturing lifting eye bolts included –

- Steel

- Stainless Steel

- Brass

- Galvanized Steel

- Titanium

- Alloy Materials

Importance of Lifting Eye Bolt in Mold Manufacturing/Maintenance

Lifting eye bolts play a crucial role in mold manufacturing and maintenance, where the handling of heavy and cumbersome molds is a routine requirement. These unassuming yet essential hardware components offer a safe and efficient solution for lifting and transporting molds throughout various stages of production and maintenance processes. Let’s explore the specific ways lifting eye bolts are indispensable in mold manufacturing and maintenance –

1. Safe and Efficient Material Handling

In mold manufacturing, molds are typically made from durable materials like steel or aluminum, making them heavy and challenging to move. Lifting eye bolts provide a secure and reliable lifting point for overhead cranes, hoists, or forklifts to safely handle these heavy molds. During different stages of production, such as mold assembly, machining, or transportation, lifting eye bolts ensure that molds are moved with precision and without damage.

2. Precise Positioning and Alignment

Precision is crucial in mold manufacturing, where molds must meet exact specifications. Lifting eye bolts, in conjunction with lifting devices, enable accurate positioning and alignment of molds during machining and assembly. This reduces the risk of damage to the molds and ensures that they meet the required tolerances and dimensions.

3. Versatility and Adaptability

Lifting eye bolts come in various types and sizes to accommodate different lifting configurations. Mold manufacturers can choose from shoulder eye bolts, swivel eye bolts, or machinery eye bolts based on the specific lifting requirements of each mold. This versatility allows for safe and efficient lifting, regardless of the mold’s shape or orientation.

4. Supporting Preventative Maintenance

Mold maintenance is essential to ensure the longevity and performance of molds. Lifting eye bolts play a vital role during routine maintenance, enabling easy removal and reinstallation of molds for cleaning, repairs, or component replacements. With the use of appropriate lifting eye bolts, maintenance tasks become more efficient, reducing downtime and improving overall productivity.

Compliance with Safety Standards

Mold manufacturing and maintenance involve the handling of heavy loads, posing potential risks to workers and equipment. The use of standard-compliant lifting eye bolts ensures that lifting operations adhere to industry safety standards and regulations. This minimizes the risk of accidents, injuries, or damage to expensive molds and equipment, while also promoting a safe working environment.

Factors To Consider While Selecting Eye Bolts

Selecting the right lifting eye bolts for mold use is crucial to ensure safe and efficient material handling in mold manufacturing and maintenance. Several factors should be carefully considered during the selection process to meet the specific requirements of the molds and ensure the safety of the lifting operation. Here are the key factors to consider –

- Load Capacity: Determine the weight of the heaviest mold that will be lifted using the eye bolt. Choose lifting eye bolts with a load capacity that exceeds the maximum weight of the molds. It is essential to avoid overloading the eye bolts, as this can lead to failure and potentially dangerous situations.

- Type of Eye Bolt: Consider the specific type of lifting eye bolt needed for the application. Depending on the lifting requirements, choose from shoulder eye bolts, swivel eye bolts, or machinery eye bolts. Shoulder eye bolts are suitable for angular lifts, swivel eye bolts offer 360-degree rotation, and machinery eye bolts are ideal for straight vertical lifts.

- Thread Size and Length: Ensure that the thread size of the lifting eye bolt matches the threaded hole or attachment point on the mold. Additionally, the length of the threaded shank should be sufficient to provide proper engagement when secured into the mold.

- Material: Select lifting eye bolts made from a suitable material based on the environment and conditions in which the molds will be used. Common materials include carbon steel, stainless steel, or galvanized steel. Stainless steel eye bolts are recommended for molds used in outdoor or corrosive environments due to their excellent corrosion resistance.

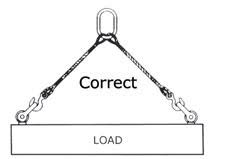

- Lifting Point Configuration: Consider the lifting point configuration on the molds. Some molds may require multiple lifting points for even weight distribution. In such cases, choose lifting eye bolts that can be integrated into lifting beams or spreader bars to accommodate the required lifting points.

- Safety Standards Compliance: Ensure that the selected lifting eye bolts comply with relevant safety standards and regulations, such as ASME B30.26 or DIN 580. Adherence to safety standards is essential for maintaining a safe working environment and preventing accidents during material handling.

- Swivel Capability: If the molds need to be rotated or repositioned during lifting, consider using swivel eye bolts to facilitate smooth and controlled movement. Swivel eye bolts offer 360-degree rotation, allowing for greater flexibility in handling the molds

- Surface Protection: For molds with delicate or precision surfaces, consider using lifting eye bolts with a protective coating or material, such as rubber or nylon. This helps prevent any damage to the mold’s surface during the lifting process.

Types of Eye Bolt

In mold manufacturing and maintenance, various types of lifting eye bolts are used. Let’s explore the common types of lifting eye bolts used for molds and their respective applications –

Shoulder Eye Bolts

Application: Shoulder eye bolts are designed for angular lifts, making them ideal for molds that need to be lifted and transported at different angles. The shoulder portion of the eye bolt provides stability and prevents side-loading during lifts, reducing the risk of bolt failure and ensuring safer material handling.

Swivel Eye Bolts

Application: Swivel eye bolts are highly versatile and provide 360-degree rotation, allowing molds to be easily rotated or repositioned during lifting. These eye bolts are suitable for molds that require precise positioning or molds that may need to be moved in various directions to fit into specific manufacturing or maintenance setups.

Machinery Eye Bolts

Application: Machinery eye bolts have a plain eyelet without a shoulder, allowing for easy pivoting during lifting. They are commonly used for straight vertical lifts and are well-suited for molds that only need to be lifted and transported in a vertical direction.

Weld-On Eye Bolts

Application: Weld-on eye bolts are designed to be permanently welded to structures or machinery, creating a reliable and permanent lifting point for molds. These eye bolts are used in specialized applications where a dedicated lifting point is required on the mold or equipment, and they are commonly used in custom lifting lug fabrication for molds.

Galvanized Eye Bolts

Application: Galvanized eye bolts are coated with a layer of zinc, providing enhanced corrosion resistance. They are used for molds that may be exposed to outdoor environments or environments with high humidity and moisture levels. The galvanized coating helps protect the eye bolts from rust and corrosion, prolonging their lifespan. Monel is used in specialized applications where molds are subjected to extreme temperatures, chemicals, or harsh environments. These eye bolts are chosen for their exceptional strength and resistance to corrosion and wear.

**Each type of lifting eye bolt has its unique advantages and applications in the context of mold manufacturing and maintenance. Mold manufacturers and maintenance teams should carefully assess their specific lifting requirements and choose the appropriate type of lifting eye bolt to ensure safe and efficient material handling while protecting the molds and equipment from potential damage. Additionally, adherence to safety standards and regulations is essential when selecting and using lifting eye bolts to promote a secure working environment and prevent accidents during material handling operations.

Safety Precautions and Best Practices

Safety is of paramount importance when using lifting eye bolts in conjunction with molds in manufacturing and maintenance processes. Ensuring proper handling and adherence to best practices can prevent accidents, protect personnel, and preserve the integrity of both the molds and the lifting equipment. Here are some essential safety precautions and best practices to follow when using lifting eye bolts with molds –

- Inspect Lifting Eye Bolts Regularly

- Match the Eye Bolt to the Lifting Equipment

- Properly Install the Eye Bolt

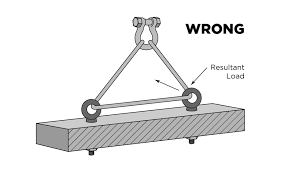

- Avoid Side Loading

- Use Swivel Eye Bolts for Rotating Molds

- Regularly Train Personnel

- Comply with Safety Standards

- Use Protective Equipment

- Document and Track Inspections

**By implementing these safety precautions and best practices, mold manufacturers and maintenance teams can create a safe and secure environment for material handling, protect valuable molds, and prevent accidents during lifting operations. Prioritizing safety not only protects personnel and equipment but also contributes to the overall efficiency and productivity of the manufacturing and maintenance processes.

Common Mistakes to Avoid

By avoiding these common mistakes and following proper safety procedures, mold manufacturers and maintenance teams can ensure the safe and successful use of lifting eye bolts during material handling operations. Prioritizing safety and adhering to best practices contribute to a secure working environment and efficient lifting processes, ultimately enhancing the productivity and reliability of the manufacturing and maintenance tasks. Here is the list of common mistakes to avoid while working with lifting eye bolts –

- Overloading the Eye Bolt

- Neglecting Inspections

- Using Worn or Damaged Eye Bolts

- Incorrect Installation

- Side Loading

- Using Non-Swivel Eye Bolts for Rotating Molds

- Ignoring Safety Standards

- Lack of Training and Education

- Not Documenting Inspections and Maintenance

- Ignoring Protective Equipment

**By avoiding these common mistakes and following proper safety procedures, mold manufacturers and maintenance teams can ensure the safe and successful use of lifting eye bolts during material handling operations. Prioritizing safety and adhering to best practices contribute to a secure working environment and efficient lifting processes, ultimately enhancing the productivity and reliability of the manufacturing and maintenance tasks.

Pros & Cons of Lifting Eye Bolts

A list of pros and cons of lifting eye bolts used for mold is given below –

Pros

- Enhanced Material Handling: Lifting eye bolts provide a safe and efficient means of handling heavy molds during manufacturing and maintenance, reducing the risk of manual handling injuries.

- Versatility: Different types of lifting eye bolts cater to various lifting configurations, enabling precise positioning and rotations when needed.

- Corrosion Resistance: Stainless steel and galvanized eye bolts offer excellent corrosion resistance, ideal for molds used in outdoor or corrosive environments.

- Load Capacity: With various load capacities available, lifting eye bolts can handle molds of different sizes and weights.

- Compliance with Standards: Lifting eye bolts designed to meet industry safety standards ensure a safer working environment and adherence to regulations.

Cons

- Incorrect Usage: Misuse of lifting eye bolts, such as overloading or side loading, can lead to eye bolt failure, causing accidents and damage to molds.

- Maintenance: Regular inspections and maintenance are necessary to ensure eye bolts are in good condition, adding to maintenance responsibilities.

- Cost: High-quality lifting eye bolts can be more expensive, impacting initial investment costs.

- Limited Load Capacity: The load capacity of the lifting eye bolt can be limiting for exceptionally heavy molds, requiring specialized lifting solutions.

- Compatibility: Ensuring compatibility between the eye bolt and lifting equipment may require additional adapters or modifications.

What is The Use of Lifting Eye Bolt?

Lifting eye bolts are used in mold manufacturing and maintenance to provide a secure and reliable lifting point for safely handling heavy molds during material handling operations. They enable precise positioning, rotations, and vertical lifts, contributing to efficient and safe material handling processes.

How to define Lifting Eye Bolt Capacity?

Lifting eye bolt capacity refers to the maximum weight the bolt can safely handle without failure. It is a crucial factor to consider when choosing the appropriate eye bolt for material handling tasks. Exceeding the capacity can lead to accidents and equipment damage while selecting the right capacity ensures safe and efficient lifting operations.

What is the Standard Lifting Eye Bolt?

Lifting eye bolt standards provide guidelines and specifications for the design, manufacture, and use of these hardware components. Standards, such as ASME B30.26 and DIN 580, ensure the quality, safety, and compatibility of lifting eye bolts in various industries. Adhering to these standards is essential to maintain a secure working environment and prevent accidents during material handling operations.