What is Thermoplastic Olefin (TPO) ?

Thermoplastic Olefin (TPO) is a class of polymeric materials that bridges the gap between rigid plastics and flexible rubbers. TPO is generally composed of a combination of polypropylene (PP), un-crosslinked ethylene-propylene rubber (EPR/EPDM), and various fillers or reinforcing agents. The distinguishing characteristic of TPO is its thermoplastic nature, meaning it can be melted, re-melted, and reshaped multiple times without losing its primary properties. Unlike thermoset rubbers that undergo irreversible curing, TPO remains processable and recyclable.

Historically, TPOs emerged in the 1970s as industries sought alternatives to PVC. Environmental concerns about chlorine-based plastics and demand for lighter, more fuel-efficient automotive components led to their widespread adoption. By the 1980s and 1990s, TPO use expanded into automotive interiors, bumpers, dashboards, and roofing membranes. Today, Thermoplastic Olefin (TPO) represents a significant proportion of thermoplastic elastomer consumption globally.

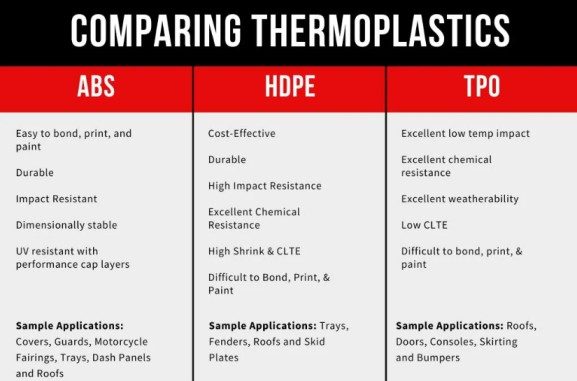

TPO stands apart when compared to other materials. With TPVs (Thermoplastic Vulcanizates), the difference lies in the processing method: TPVs involve dynamic vulcanization, imparting superior elasticity. TPOs, on the other hand, are physically blended, offering a more cost-effective balance between rigidity and toughness. Against PVC, TPO is lighter, halogen-free, and recyclable, making it a sustainable choice. When compared with EVA (Ethylene Vinyl Acetate), EVA finds applications in foams and soft goods, whereas TPO excels in structural durability.

The combination of these features makes Thermoplastic Olefin (TPO) a versatile material with applications ranging from construction roofing membranes to automotive trims. Its recyclability, durability, and lightweight properties also position it as a material of the future in sustainable engineering.

Composition of Thermoplastic Olefin

The formulation of TPO involves a careful balance of components to achieve the required mechanical, thermal, and environmental performance.

Polypropylene (PP): Acting as the backbone, PP provides stiffness, rigidity, and chemical resistance. It has a semi-crystalline structure with a melting point around 160–170°C, which defines the upper thermal service limit of TPO.

Ethylene-Propylene Rubber (EPR/EPDM): This rubbery phase adds softness, elasticity, and impact strength. It improves flexibility at low temperatures and enhances toughness during mechanical stress. The proportion of rubber directly influences the hardness and resilience of the TPO.

Fillers: Talc, calcium carbonate, glass fibers, or other minerals are introduced to enhance stiffness, lower costs, and provide better dimensional stability. Depending on application, filler content can range from 10–40%.

Additives:

- Antioxidants: Protect against oxidative degradation during processing and service life.

- UV Stabilizers: Prevent photo-degradation in outdoor environments.

- Flame Retardants: Enhance fire resistance for safety-critical applications.

- Pigments: Provide color consistency.

- Processing Aids: Assist in extrusion and injection molding by reducing friction and improving flow.

Molecular Structure: TPO exhibits dual morphology, combining crystalline PP domains with amorphous rubber domains. This structure allows the material to exhibit rigidity while maintaining flexibility. The degree of crystallinity depends on the PP-to-rubber ratio and processing conditions, which can be tailored to meet application-specific demands.

Properties of Thermoplastic Olefin

TPO offers a wide range of properties that can be tuned by modifying its composition and processing.

Physical Properties: TPO is lightweight, with density ranging between 0.86 and 0.93 g/cm³. Shore hardness can range from soft rubber-like values (~60A) to hard plastic-like values (~70D). Tensile strength falls in the 8–25 MPa range, while elongation at break can reach 600%, depending on formulation.

Mechanical Properties: Impact resistance is one of the defining traits of TPO, making it useful in automotive applications like bumpers. Its stiffness can be controlled through filler loading or PP content, making it adaptable to structural or flexible applications.

Thermal Properties: TPO maintains performance between -40°C and +100°C, with short-term resistance up to 120°C. While it does not tolerate high continuous temperatures, its heat-aging properties can be improved with antioxidants and stabilizers.

Chemical Resistance: TPO is resistant to acids, bases, and aqueous salts, which makes it suitable for harsh outdoor or chemical environments. However, it shows poor resistance to hydrocarbons, oils, and strong solvents.

Weather Resistance: With UV stabilizers, TPO exhibits strong resistance to sunlight, ozone, and atmospheric degradation, explaining its dominance in roofing membranes and automotive exteriors.

Environmental Profile: TPO is recyclable, halogen-free, and requires less energy to produce than PVC. Its lightweight nature reduces fuel consumption in vehicles.

Manufacturing of Thermoplastic Olefin

The manufacturing of TPO involves polymerization, compounding, and shaping into final products.

Step 1 – Polypropylene Production: PP is produced by polymerizing propylene monomers using Ziegler-Natta or metallocene catalysts. These control the molecular weight and crystallinity of PP, which affect rigidity and processing.

Step 2 – Rubber Production: Ethylene and propylene monomers are copolymerized to form EPR or EPDM rubber. EPDM includes diene monomers that enhance flexibility and weather resistance.

Step 3 – Blending Process: PP and rubber are blended using twin-screw extruders under high shear. Fillers, stabilizers, pigments, and other additives are incorporated. The molten mixture is pelletized for easy transportation and further processing.

Processing Methods:

- Injection Molding: Produces complex parts like dashboards and trims.

- Extrusion: Creates roofing membranes, pipes, and sheets.

- Blow Molding: Makes containers and tanks.

- Thermoforming: Shapes packaging and liners.

Processing Conditions: TPO typically processes between 180–240°C. Mold temperatures range from 20–60°C. Due to low moisture absorption, drying is generally unnecessary.

Grades of Thermoplastic Olefin

TPO materials are classified into multiple grades depending on the intended application and required properties. Each grade balances stiffness, impact strength, flexibility, and processability differently.

Typically used in non-critical applications like packaging or secondary automotive trims.

General-Purpose TPO

Balanced mechanical and thermal properties.

Widely used in consumer goods, packaging, and basic automotive parts.

Cost-effective with medium impact strength.

High-Impact TPO

Contains higher EPDM content for superior impact resistance.

Ideal for automotive bumpers, dashboards, and protective casings.

Slightly lower stiffness compared to general grades.

High-Stiffness TPO

Higher polypropylene content or reinforcement with talc/glass fibers.

Enhanced modulus of elasticity and dimensional stability.

Suitable for load-bearing parts, construction panels, and appliance housings.

UV-Stabilized TPO

Incorporates UV absorbers and stabilizers to resist sunlight degradation.

Common in roofing membranes, outdoor automotive trims, and playground equipment.

Prevents brittleness and color fading over time.

Flame-Retardant TPO

Modified with flame-retardant additives like halogen-free phosphorous or nitrogen-based systems.

Used in electrical housings, appliances, and public transportation interiors.

Meets fire safety standards (UL 94, FMVSS 302).

Weatherable TPO

Enhanced for long-term outdoor exposure with additives that resist UV, ozone, and moisture.

Extensively used in roofing and waterproofing membranes.

Offers durability of 20+ years in construction.

Soft-Touch TPO

Engineered with higher rubber phase for enhanced softness and tactile feel.

Found in automotive interiors, armrests, and household items.

Improves comfort and ergonomics.

Color-Matched TPO

Pre-compounded with pigments for aesthetic appeal.

Used in visible automotive components, consumer products, and decorative parts.

Eliminates need for secondary painting or coating.

Reinforced TPO

Blended with glass fiber or mineral fillers to increase stiffness and dimensional stability.

Applied in structural automotive components, roofing sheets, and appliance back panels.

Balances strength with reduced shrinkage.

Recycled TPO Grades

Incorporate post-industrial or post-consumer recycled content.

Eco-friendly and cost-effective.

Applications of Thermoplastic Olefin

Automotive Industry: TPO has revolutionized automotive manufacturing. It replaces metals and PVC in bumpers, dashboards, trims, and interior panels. The lightweight nature enhances fuel efficiency, while recyclability supports sustainable manufacturing.

Construction Industry: Roofing membranes are a leading application. TPO roofing sheets provide durability, UV resistance, and a service life exceeding 20 years. They are also used for waterproofing layers and building profiles.

Consumer Goods: Luggage shells, footwear soles, and sports equipment rely on TPO for impact resistance and lightweight durability.

Electronics: TPO is used in wire coatings, connectors, and housings where electrical insulation and durability are essential.

Packaging: TPO can form rigid containers and blister packs that are resistant to environmental stress cracking.

Medical: Non-toxic and chemical-resistant, TPO finds use in tubing, seals, and medical-grade packaging.

Testing and Standards

Ensuring TPO performance requires adherence to standardized testing.

Mechanical Tests: Tensile testing (ASTM D638) evaluates strength and elongation. Hardness (ASTM D2240) confirms flexibility levels. Impact testing (ASTM D256) determines toughness.

Weather/Heat Resistance: Accelerated UV exposure (ASTM G154) simulates outdoor performance. Heat aging (ASTM D573) measures long-term durability.

Roofing Standards: ASTM D6878 governs TPO roofing membranes, requiring performance in flexibility, weatherability, and seam strength. Fire standards by FM Approvals ensure safety compliance.

Automotive Standards: SAE J2027 specifies automotive use, covering properties like impact resistance, aging, and recyclability.

Advantages of Thermoplastic Olefin

- Lightweight: Reduces vehicle weight, lowers fuel consumption.

- Impact Resistance: Suitable for bumpers and roofing against hail.

- Flexibility & Rigidity Balance: Enables wide-ranging applications.

- Weather Resistance: Reliable for outdoor exposure.

- Cost-Effective: More affordable than engineering plastics.

- Recyclable: Contributes to circular economy.

- Easy Processing: Supports injection molding, extrusion, and thermoforming.

Limitations of Thermoplastic Olefin

- High-Temperature Limitation: TPO cannot sustain service beyond 120°C.

- Chemical Resistance Gaps: Vulnerable to hydrocarbons and oils.

- Scratch Resistance: Susceptible to cosmetic damage.

- Elasticity Limitations: Less elastic compared to TPVs.

- Performance Variability: Dependent on formulation quality.

Future Trends in Thermoplastic Olefin

- Nanocomposites: Nanoclays and graphene for strength and barrier properties.

- Bio-based TPO: Derived from renewable feedstocks, reducing carbon footprint.

- Advanced Stabilizers: Enhanced UV resistance for longer service life.

- Foamed TPOs: Lightweight alternatives in vehicles.

- Smart TPOs: Conductive or self-healing for advanced applications.

Conclusion

Thermoplastic Olefins (TPOs) are advanced polymer blends of polypropylene and ethylene-propylene rubber that combine the strength of plastics with the flexibility of elastomers. TPO offers durability, impact resistance, UV stability, and cost efficiency, making it widely used in automotive, construction, consumer goods, and electrical industries. Its recyclability supports sustainability goals, while multiple grades allow customization for specific performance needs.

With applications ranging from car bumpers to roofing membranes, TPO stands out as a versatile, lightweight, and eco-friendly material. This guide provides comprehensive insights for students, professors, and professionals exploring TPO’s science, processing, and real-world applications.

FAQ’s

What is TPO material?

TPO (Thermoplastic Olefin) is a polymer blend of polypropylene and ethylene-propylene rubber. It combines the strength of plastics with the flexibility of rubber, making it highly versatile for automotive, construction, and consumer applications.

What is TPO used for?

TPO is widely used in automotive bumpers, dashboards, and trims; roofing membranes in construction; wire and cable insulation; appliance housings; and consumer goods like luggage and footwear.

Is TPO the same as rubber?

No, TPO is not pure rubber. It is a blend of thermoplastic (polypropylene) and elastomeric rubber (EPDM/EPR). This gives it elastic properties like rubber but with thermoplastic processability.

What are the advantages of TPO roofing?

TPO roofing membranes are lightweight, UV-resistant, energy-efficient, recyclable, and durable (lasting 20–30 years). They are preferred for commercial and residential flat roofs.

Is TPO material recyclable?

Yes, TPO is recyclable. It can be reprocessed into new parts or blended with virgin material, making it a sustainable choice compared to many thermoset rubbers.

How does TPO compare with PVC?

TPO is more environmentally friendly, lighter, and often more flexible than PVC. However, PVC has higher chemical resistance and can withstand certain solvents better.

What temperatures can TPO withstand?

TPO typically functions between -40°C to 100°C, depending on the grade. Some reinforced or modified types can tolerate slightly higher temperatures.

Is TPO waterproof?

Yes, TPO is waterproof, which is why it is widely used in roofing membranes and waterproofing applications.

Is TPO safe for medical use?

Non-toxic and FDA-compliant grades of TPO are used in non-critical medical devices and disposable equipment, although not in implants or highly critical applications.

Why is TPO popular in the automotive industry?

TPO reduces vehicle weight, improves fuel efficiency, and provides impact resistance and design flexibility. It is also cost-effective and recyclable, aligning with sustainability goals.

- Thermoplastic Elastomers (TPE) Material Explained: Types, Properties, Applications & Market

- Comprehensive Guide on Thermoplastic Olefin (TPO) Material – Point-to-Point Explanation

- All-in-One Hot Runner Mold Repair and Troubleshooting Manual

- Comprehensive guide on EPDM in Transfer Molding: Definition, Composition, Manufacturing, Shelf Life, Properties, Pros & Cons, Applications, FAQs.

- Mold Preventive Maintenance Checksheet

Your blog is a constant source of inspiration for me. Your passion for your subject matter is palpable, and it’s clear that you pour your heart and soul into every post. Keep up the incredible work!

Your blog is a breath of fresh air in the crowded online space. I appreciate the unique perspective you bring to every topic you cover. Keep up the fantastic work!

Your blog is a beacon of light in the often murky waters of online content. Your thoughtful analysis and insightful commentary never fail to leave a lasting impression. Keep up the amazing work!

I am really impressed with your writing skills and also with the layout on your blog. Is this a paid theme or did you customize it yourself? Either way keep up the nice quality writing, it’s rare to see a great blog like this one nowadays..

As a Newbie, I am always searching online for articles that can benefit me. Thank you

It is appropriate time to make some plans for the longer term and it is time to be happy. I’ve read this publish and if I may just I desire to suggest you some fascinating things or suggestions. Maybe you could write next articles regarding this article. I wish to learn more issues approximately it!

Hi there! This is my first visit to your blog! We are a collection of volunteers and starting a new project in a community in the same niche. Your blog provided us useful information to work on. You have done a outstanding job!