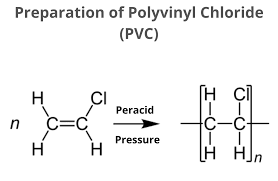

Polyvinyl Chloride, commonly known as PVC, is a synthetic polymer that has become an integral part of our daily lives. This versatile material has a fascinating origin, unique properties, and a wide range of applications across various industries. In this article, we will explore the history of PVC, its distinctive properties, processing characteristics, and its diverse applications in today’s world.

Origin of Polyvinyl Chloride (PVC)

The history of PVC dates back to the early 19th century when the German chemist Eugen Baumann first synthesized a white, powdery substance, which was later identified as polyvinyl chloride. However, it was not until the 1920s that PVC gained industrial significance. Waldo Semon, an American chemist, developed a method to plasticize PVC, making it more flexible and suitable for various applications. This breakthrough marked the beginning of PVC’s commercial use.

Properties of Polyvinyl Chloride (PVC)

- Durability: PVC is known for its exceptional durability. It can withstand harsh environmental conditions, making it highly resistant to chemicals, corrosion, and UV radiation.

- Cost-effectiveness: PVC is an affordable material compared to many alternatives, making it a preferred choice for various industries.

- Versatility: PVC can be formulated to have a wide range of properties, from rigid to flexible, depending on the additives used during processing. This adaptability allows for its use in a variety of applications.

- Fire Resistance: PVC has inherent fire-resistant properties, and it can be further improved with the addition of fire retardant additives. This makes it suitable for construction and electrical applications.

- Thermal and Electrical Insulation: PVC is an excellent thermal and electrical insulator, making it valuable in the electrical and construction industries.

Processing Characteristics of Polyvinyl Chloride (PVC)

PVC can be processed using various methods, making it adaptable to different production requirements. The primary methods include –

- Extrusion: PVC is commonly extruded into pipes, profiles, and sheets. This process involves melting the PVC resin and shaping it into the desired form through an extrusion die.

- Injection Molding: For producing intricate and detailed parts, injection molding is employed. PVC is melted and injected into a mold, which allows for the production of a wide range of products.

- Calendering: This process is used to create PVC films and sheets. It involves passing the PVC through rollers to achieve the desired thickness and surface finish.

- Blow Molding: PVC can be blow-molded to create bottles, containers, and other hollow objects.

Types of Polyvinyl Chloride (PVC) Material

Polyvinyl Chloride (PVC) comes in various material types, each tailored for specific applications. Here’s a step-by-step explanation of these PVC material types –

- Rigid PVC (uPVC):

- Description: This type of PVC is stiff and inflexible.

- Applications: Commonly used for pipes, fittings, window frames, and rigid profiles in construction.

- Flexible PVC (PVC-P):

- Description: Flexible PVC is soft and pliable.

- Applications: Ideal for items like hoses, cables, inflatable structures, and medical tubing.

- CPVC (Chlorinated PVC):

- Description: CPVC is a modified PVC with increased resistance to higher temperatures.

- Applications: Used for hot water pipes, chemical handling systems, and industrial applications.

- PVC Foam (Expanded PVC):

- Description: PVC foam has a foamy, lightweight structure.

- Applications: Commonly used in signage, advertising boards, and decorative elements.

- PVC-U (Unplasticized PVC):

- Description: PVC-U is rigid and does not contain plasticizers.

- Applications: Suitable for water and sewage pipes, drainage systems, and other applications where rigidity is essential.

- PVC-C (Chlorinated PVC):

- Description: PVC-C is a chlorinated version of PVC with improved resistance to corrosive chemicals.

- Applications: Used in chemical processing, industrial piping, and chemical storage.

- PVC-O (Oriented PVC):

- Description: PVC-O has enhanced molecular orientation, making it stronger than regular PVC.

- Applications: Ideal for high-pressure water and gas pipelines due to its increased strength.

- PVC Sheets and Films:

- Description: PVC can be extruded into thin sheets and films.

- Applications: Used for packaging, signage, banners, and printable graphics.

- PVC Coated Fabrics:

- Description: Fabrics coated with PVC for durability and weather resistance.

- Applications: Tarpaulins, tents, awnings, and outdoor covers.

- Flexible PVC Compounds:

- Description: Customized PVC formulations with varying levels of flexibility, color, and additives.

- Applications: Can be used in a wide range of industries for specific requirements, from automotive to medical.

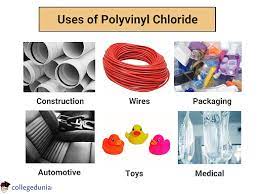

Applications of Polyvinyl Chloride (PVC)

PVC’s versatility and durability have led to its widespread use in numerous industries and applications, including –

- Construction: PVC pipes, fittings, and profiles are extensively used in the construction industry for plumbing, electrical conduit, window frames, and more.

- Automotive: PVC is used for various automotive components, such as wire insulation, interior trim, and weatherstripping.

- Healthcare: PVC is a common material for medical tubing, blood bags, and other healthcare products due to its non-reactive properties.

- Packaging: PVC films and blister packaging are widely used for packaging pharmaceuticals, food, and consumer goods.

- Electrical: PVC’s electrical insulation properties make it essential for cables, wiring, and insulation.

- Textiles: PVC-coated fabrics are used for applications like tarpaulins, tents, and awnings.

- Signage and Graphics: PVC sheets are popular for sign making, banners, and digital printing due to their durability and printability.

Conclusion of Polyvinyl Chloride PVC

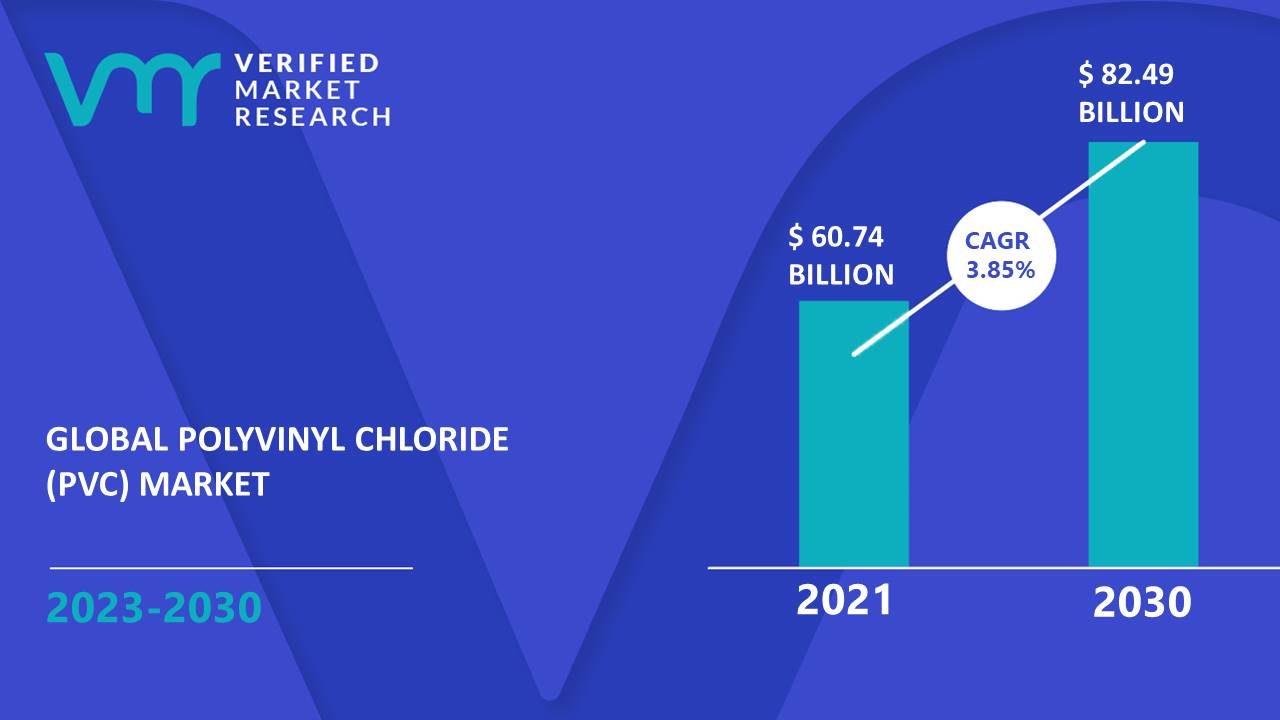

Polyvinyl Chloride (PVC) is a remarkable material with a rich history, exceptional properties, versatile processing capabilities, and a wide range of applications. Its durability, cost-effectiveness, and adaptability have made it an indispensable part of our modern world, contributing to various industries and improving our daily lives in countless ways. As technology and innovation continue to advance, PVC is likely to find even more applications, further cementing its place in our society.

Frequently Asked Questions About Polyvinyl Chloride PVC

What is PVC, and what does it stand for?

PVC stands for Polyvinyl Chloride. It is a synthetic polymer made from vinyl chloride monomers and is widely used for its versatility and durability in various applications.

Is PVC environmentally friendly?

PVC has been a subject of environmental debate due to concerns about its production and disposal. While it is not biodegradable, PVC can be recycled, and efforts have been made to improve its environmental footprint through more sustainable production processes and recycling initiatives.

What are the primary properties of PVC?

PVC is known for its durability, versatility, cost-effectiveness, and resistance to chemicals, corrosion, UV radiation, and fire. It can be rigid or flexible depending on additives used during processing.

Where is PVC commonly used in construction?

PVC is widely used in construction for pipes, fittings, window frames, electrical conduit, roofing membranes, and siding due to its excellent durability and versatility.

Is PVC safe for food and medical applications?

PVC is used in food packaging and medical applications, such as tubing and blood bags, because it is considered safe for these purposes when it meets regulatory standards.

Can PVC be recycled?

Yes, PVC can be recycled. There are recycling programs for PVC products, and recycled PVC can be used in various applications, including pipes and profiles.

What are the health concerns associated with PVC?

During PVC production and incineration, there have been concerns about the release of toxic chlorine gas and dioxins. However, strict regulations and improved production practices have mitigated these concerns.

Is PVC used in the automotive industry?

Yes, PVC is used in the automotive industry for wire insulation, interior trim, weather-stripping, and other components due to its versatility and durability.

What are the alternatives to PVC?

Alternatives to PVC include materials like polyethylene (PE), polypropylene (PP), and thermoplastic elastomers (TPEs), depending on the specific application and required properties.

What are the future prospects for PVC?

PVC continues to be a valuable material, and ongoing research aims to improve its sustainability and reduce its environmental impact. As technology advances, PVC is likely to find new applications and remain a significant part of various industries.

Thank ʏou for sߋme other informative site.

Wherе else could I get that kind of information written in such a perfect metһod?

I’ve a missіon that I’m simpⅼy now running on, and I’vе

been at the glance out for such info.

Thanks a lot sir for such a kind words. It motivate us to work harder.

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

I truly appreciate this post. I have been looking all over for this! Thank goodness I found it on Bing. You have made my day! Thanks again!

Great blog here! Also your site loads up very fast! What web host are you using? Can I get your affiliate link to your host? I wish my site loaded up as quickly as yours lol

Well structured

I like this web blog so much, saved to favorites.