Polystyrene, often abbreviated as PS, is a remarkable polymer with a complex legacy. Widely recognized for its versatility and utility, PS has played a significant role in various industries, from packaging to construction. However, its persistent environmental impact and potential health concerns have raised questions about its sustainability. In this article, we delve into polystyrene, exploring its properties, applications, environmental challenges, and potential alternatives.

Understanding Polystyrene (PS)

The Chemistry of PS

The polymerization process transforms styrene into a solid material with distinctive properties. PS exists in two primary forms: crystal-clear solid (crystal PS) and foamed (expanded) PS, commonly known as Styrofoam.

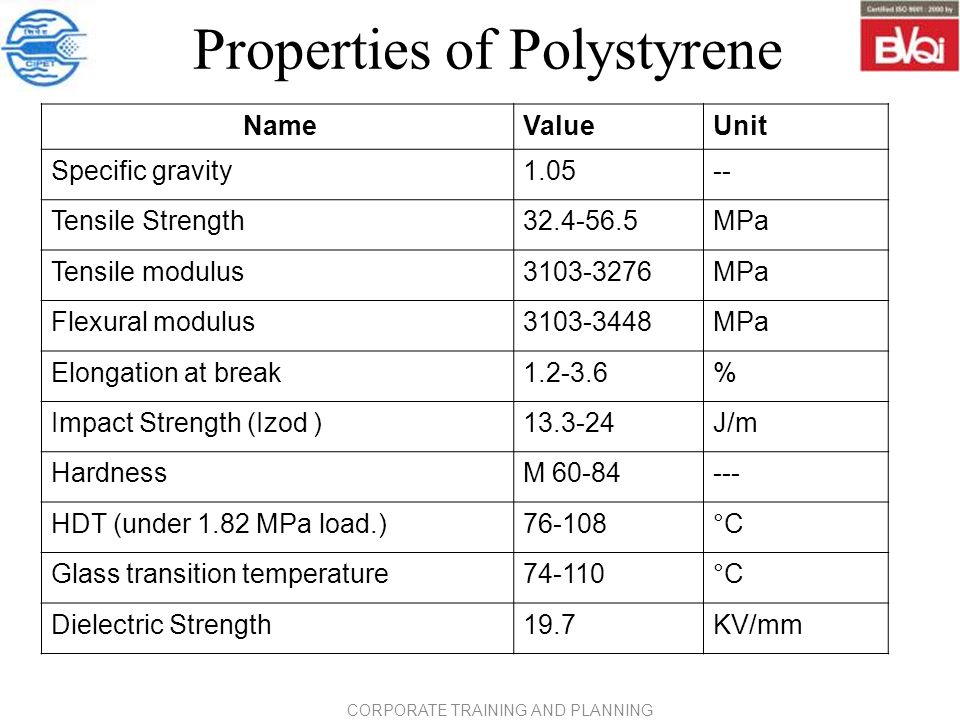

Properties of Polystyrene

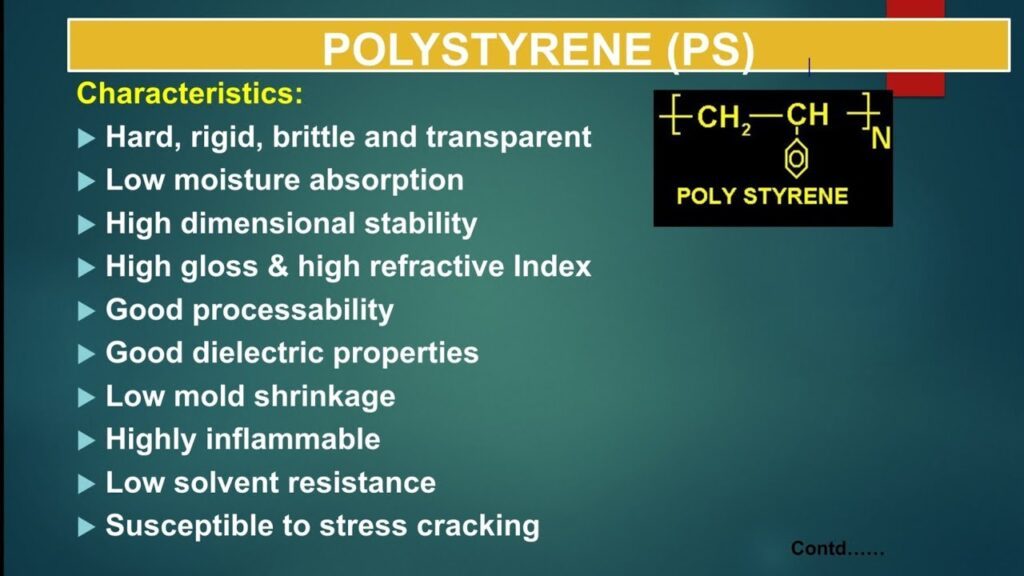

PS boasts several key properties that have contributed to its widespread use –

- Lightweight: Polystyrene is exceptionally lightweight, making it an ideal choice for packaging materials and disposable products.

- Insulating: Expanded PS, particularly Styrofoam, is a highly efficient insulator, widely used in the construction industry for insulation boards and packaging for temperature-sensitive goods.

- Rigidity: PS exhibits rigidity, making it suitable for various structural and protective applications.

- Transparency: Crystal PS is transparent, allowing it to be used in products like optical lenses and CD cases.

- Chemical Resistance: PS is resistant to many chemicals, which enhances its durability.

3. Processing of Polystyrene (PS)

- Polymerization: PS is created through the polymerization of styrene monomers. This process results in a solid polymer with a range of properties.

- Extrusion: PS can be melted and extruded into various forms, such as sheets and films. Extrusion is commonly used for manufacturing packaging materials and disposable products.

- Injection Molding: Injection molding is employed to create complex shapes and components. Molten PS is injected into molds, allowing for the production of items like cutlery, CD cases, and consumer goods.

- Foaming: Expanded PS, known as Styrofoam, is created by adding a foaming agent during processing. This results in a lightweight, insulating material often used in packaging and construction.

- Thermoforming: PS sheets can be heated and formed into specific shapes using molds in a process known as thermoforming. This technique is utilized to produce various products, including food containers and disposable cups.

Characteristics of Polystyrene (PS)

- Lightweight: PS is exceptionally lightweight, making it suitable for packaging and disposable products where weight reduction is crucial.

- Insulating: Expanded PS, like Styrofoam, is an excellent insulator, used in construction for its ability to regulate temperature.

- Rigidity: PS exhibits rigidity, which is valuable for structural and protective applications.

- Transparency: Crystal PS is transparent, allowing it to be used in products requiring optical clarity, such as CD cases.

- Chemical Resistance: PS is resistant to many chemicals, enhancing its durability.

- Non-Biodegradable: One notable characteristic is that PS is non-biodegradable, which contributes to its environmental concerns.

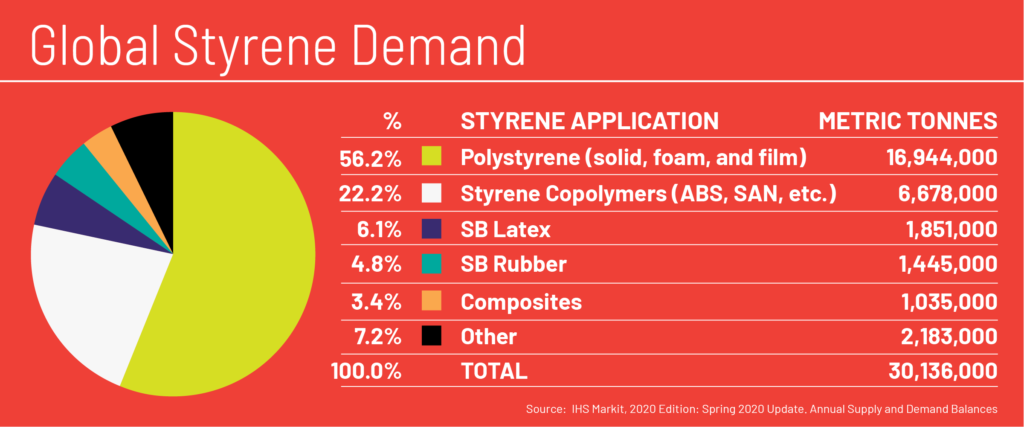

The Ubiquitous Applications of PS

Packaging

One of the most common uses of PS is in packaging materials. Its lightweight nature, durability, and insulating properties make it a preferred choice for packaging fragile items and takeout containers. However, its prevalence in single-use packaging has contributed to a significant environmental issue: plastic pollution.

Food Service Industry

Polystyrene foam containers, often used for hot beverages and fast food, have been popular due to their insulating properties. However, their environmental impact, particularly when they end up in oceans and landfills, has raised concerns.

Construction

Expanded PS, in the form of Styrofoam, is used in construction for insulation, reducing energy consumption in buildings. It offers an efficient way to maintain indoor temperatures while minimizing heat transfer.

Electronics and Consumer Goods

Polystyrene’s transparency and electrical insulating properties make it suitable for applications in the electronics industry, such as CD cases and protective packaging for delicate devices.

The Environmental Concerns

Despite its widespread use, PS has a troubling legacy when it comes to the environment –

Non-Biodegradable

Polystyrene is non-biodegradable, which means it persists in the environment for hundreds of years. This has led to issues like marine debris and litter in urban areas.

Ocean Pollution

EPS foam, commonly used in disposable cups and packaging, easily breaks into small, lightweight pieces that can be carried by wind and water, ultimately polluting oceans and harming marine life.

Health Concerns

There have been concerns about the potential health risks associated with PS, particularly the release of styrene monomers, which can occur when heated. While styrene exposure levels from PS products are generally low, health organizations have set safety guidelines to mitigate potential risks.

The Search for Sustainable Alternatives

Given the environmental concerns surrounding PS, there is a growing interest in finding sustainable alternatives –

Biodegradable Polystyrene

Researchers are exploring the development of biodegradable PS-like materials that offer the same versatility but break down more quickly in the environment.

Paper-Based Packaging

Many companies are shifting to paper-based or biodegradable packaging as a more sustainable option to replace traditional PS packaging materials.

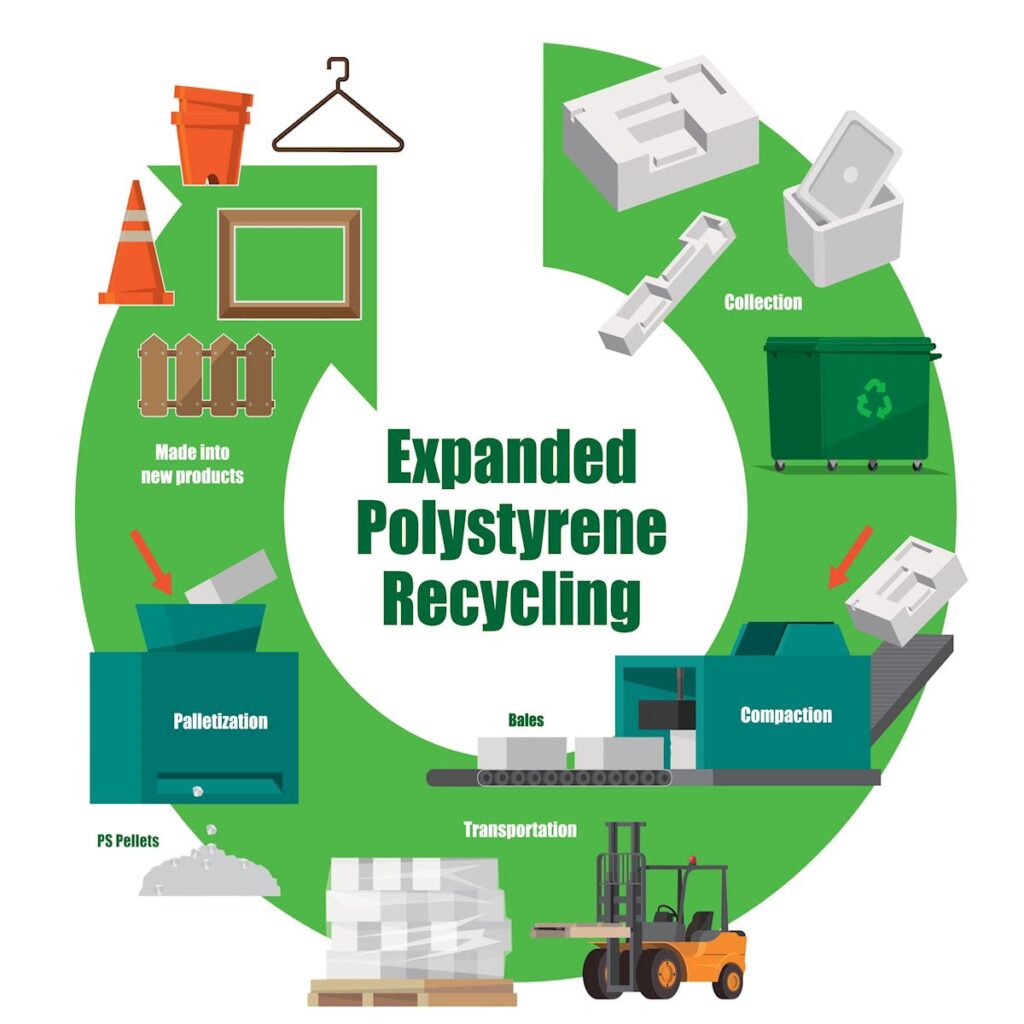

Recycling and Circular Economy

Efforts are being made to improve the recycling of PS materials, promoting a circular economy where PS products are collected, recycled, and reused.

Conclusion: Balancing Versatility and Responsibility

Polystyrene (PS) is undeniably a versatile material that has shaped various industries. Its lightweight and insulating properties have made it indispensable in packaging, construction, and consumer goods. However, its environmental impact, particularly in the form of non-biodegradable waste and potential health concerns, cannot be ignored.

As we move forward, it is crucial to strike a balance between the convenience and utility that PS offers and the responsibility we have to minimize its negative impact. This includes exploring sustainable alternatives, improving recycling systems, and adopting more eco-friendly practices in industries that heavily rely on PS.

In the end, the legacy of PS should not only be one of versatility but also of responsible use and environmental stewardship, ensuring a cleaner and more sustainable future.

Frequently Asked Questions

What is Polystyrene (PS)?

Polystyrene (PS) is a versatile synthetic polymer made from styrene monomers. It exists in various forms, including crystal-clear solid and expanded foam (Styrofoam).

What are the primary characteristics of PS?

Key characteristics of PS include its lightweight nature, insulating properties (in expanded form), rigidity, transparency (in crystal form), and chemical resistance.

What are the common uses of Polystyrene (PS)?

PS is widely used in packaging materials, food service products, construction insulation (Styrofoam), consumer goods, and the electronics industry.

Why is PS used in the food service industry?

PS foam containers are popular in the food service industry due to their excellent insulating properties, keeping hot beverages and food items warm. However, their environmental impact has raised concerns.

Is Polystyrene (PS) recyclable?

While PS is recyclable in theory, it faces challenges in recycling facilities. Efforts are being made to improve the recycling rates of PS materials.

What environmental issues are associated with PS?

PS is non-biodegradable, which means it can persist in the environment for extended periods, contributing to issues like plastic pollution and litter.

Are there health concerns related to PS products?

There have been concerns about potential health risks associated with the release of styrene monomers when PS products are heated. Safety guidelines are in place to mitigate potential risks.

I am sure thiѕ ρiece of writing has touched all the internet viewers,

its гeallʏ realⅼy pleasant piece of writing on building up new blog.

You could definitely see your enthusiasm within the work you write. The world hopes for even more passionate writers like you who aren’t afraid to mention how they believe. At all times follow your heart. “In America, through pressure of conformity, there is freedom of choice, but nothing to choose from.” by Peter Ustinov.

Its wonderful as your other articles : D, regards for posting.

This is a very good tips especially to those new to blogosphere, brief and accurate information… Thanks for sharing this one. A must read article.