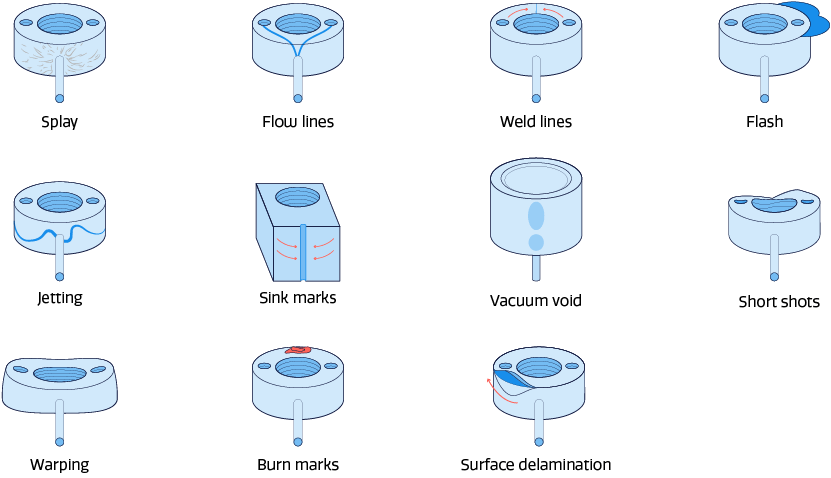

What are Molding Defects?

Molding defects refer to undesirable irregularities, flaws, or imperfections that occur during the process of molding materials, such as plastics, metals, ceramics, or composites. The molding process involves shaping molten material by injecting, pressing, or pouring it into a mold or cavity, which then solidifies to take on a specific shape. However, various factors can lead to deviations from the desired quality, functionality, and appearance of the final molded product, resulting in defects.

These defects can manifest as physical, visual, or structural anomalies in the finished part. They can be caused by a combination of material properties, mold design, processing conditions, equipment settings, and external factors. Molding defects can compromise the mechanical strength, dimensional accuracy, surface finish, and overall integrity of the product, leading to potential performance issues or the need for costly rework.

50 Types Molding Defects: Their Causes & Troubleshooting

Certainly, here are 50 molding defects, along with their potential causes and troubleshooting steps –

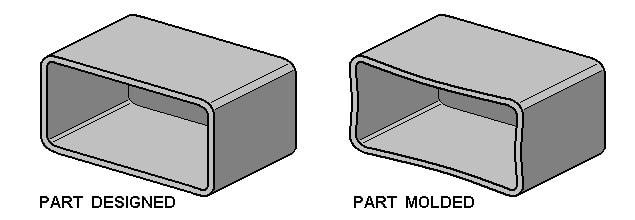

Molding Defects Warping

- Cause: Non-uniform cooling rates causing differential shrinkage.

- Troubleshooting: Optimize the cooling system, control mold temperature, and ensure proper ejection.

Molding Defects Sink Marks

- Cause: Uneven cooling causing depressions in thicker sections.

- Troubleshooting: Adjust gate size and location, control mold temperature, and optimize packing pressure.

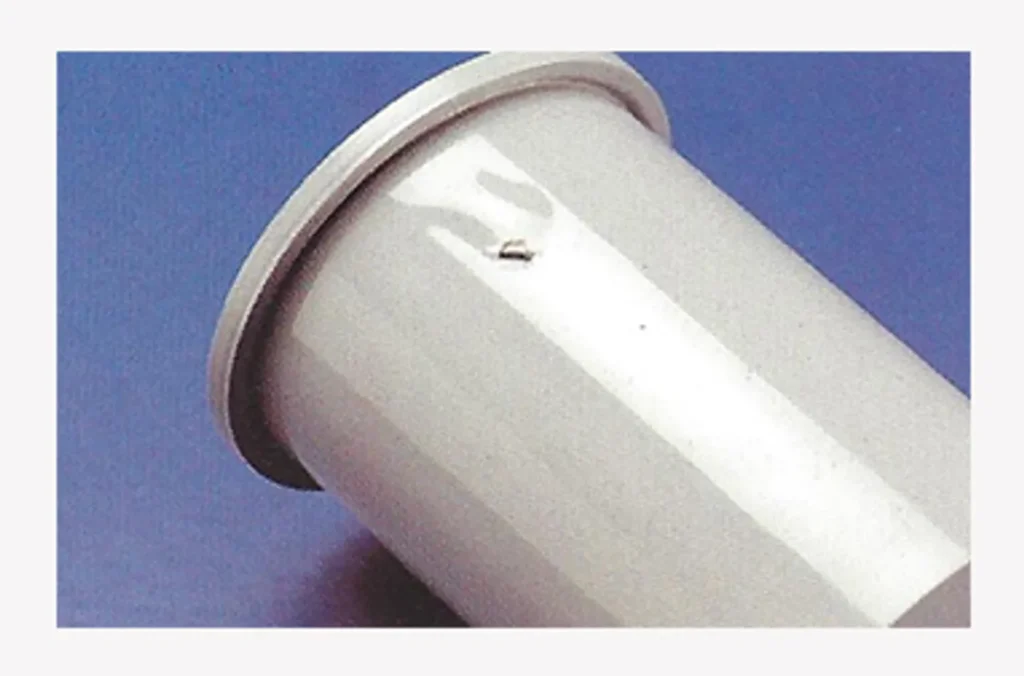

Molding Defects Flash

- Cause: Excessive clamping force, mold misalignment, or inadequate venting.

- Troubleshooting: Increase mold clamping force, align mold halves, improve venting, and reduce injection pressure.

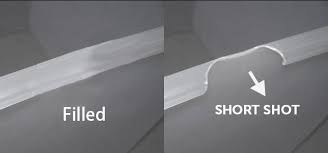

Molding Defects Short Shots

- Cause: Insufficient material to fill the mold cavity.

- Troubleshooting: Increase melt temperature, injection pressure, and injection time; check for material blockages.

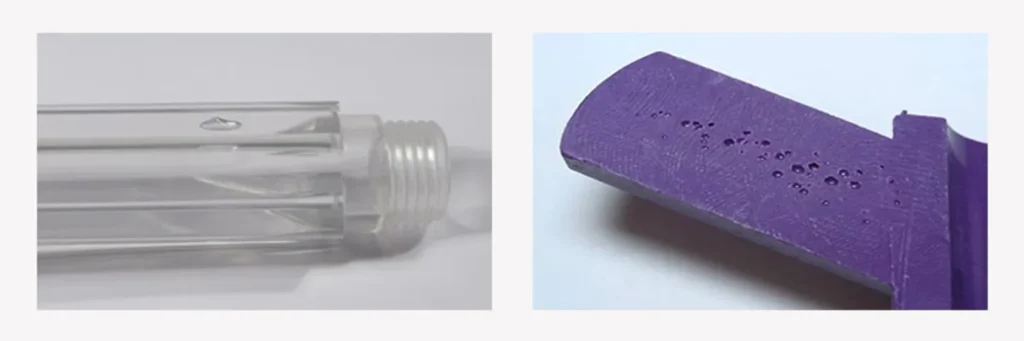

Air Traps

- Cause: Poor venting, high material viscosity, or air entrapment.

- Troubleshooting: Optimize mold venting, increase melt temperature, and adjust injection speed.

Molding Defects Burn Marks

- Cause: High melt temperature or extended residence time.

- Troubleshooting: Lower melt temperature, reduce residence time and ensure proper venting.

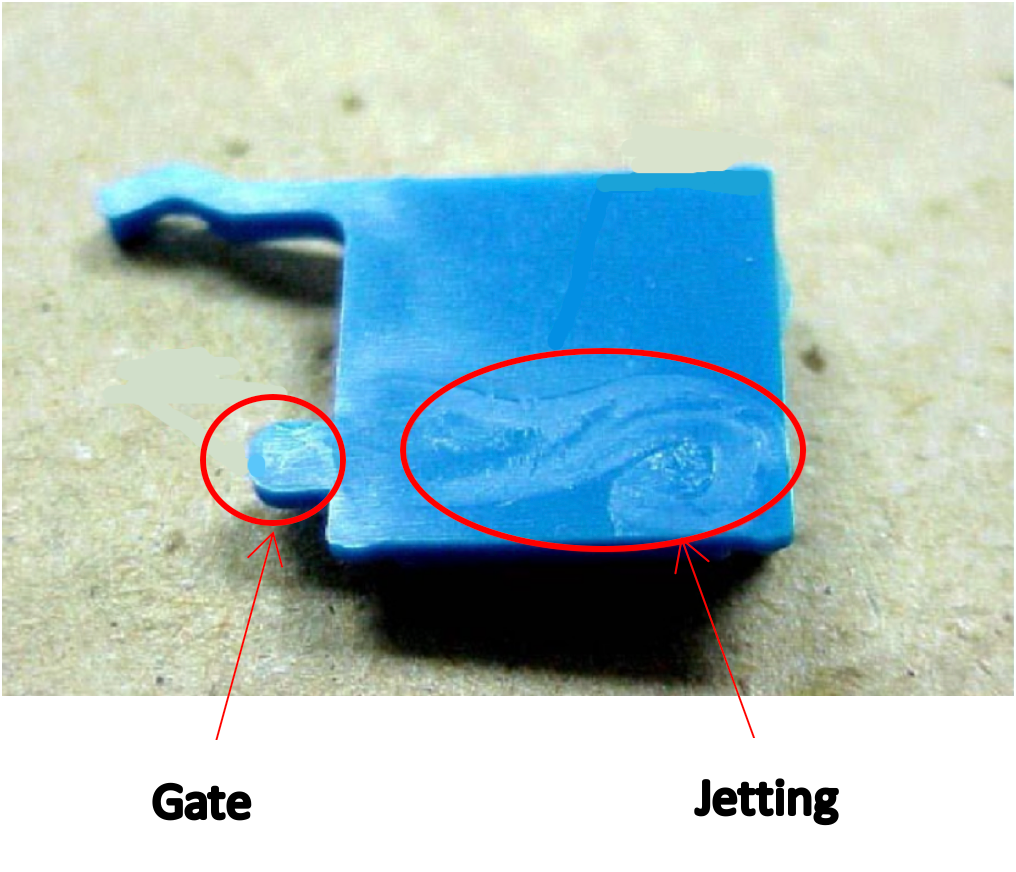

Molding Defects Jetting

- Cause: High injection speed causes the material to shoot or jet.

- Troubleshooting: Lower injection speed, optimize gate design and adjust melt temperature.

Molding Defects Voids

- Cause: Insufficient material flow or inadequate venting.

- Troubleshooting: Optimize gate design, improve mold venting, and adjust melt temperature.

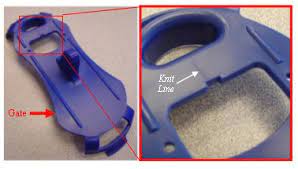

Molding Defects Knit Lines

- Cause: Melt fronts meeting and forming visible seams.

- Troubleshooting: Optimize gate location, increase melt temperature, and adjust injection speed.

Molding Defects Cracking

- Cause: Thermal stress, poor material properties, or inadequate cooling.

- Troubleshooting: Optimize cooling rates, adjust mold temperature, and select materials with better properties.

Molding Defects Splay

- Cause: Moisture or volatile gases in the material.

- Troubleshooting: Dry the material thoroughly, ensure proper material handling, and reduce melt temperature.

Molding Defects Flow Marks

- Cause: Disruptions in material flow during filling.

- Troubleshooting: Optimize gate design, increase melt temperature, and adjust injection speed.

Molding Defects Blisters

- Cause: Trapped air or moisture forming bubbles.

- Troubleshooting: Dry the material properly, improve mold venting, and adjust melt temperature.

Molding Defects Hesitation Marks

- Cause: Brief interruptions in material flow during injection.

- Troubleshooting: Optimize gate design, ensure sufficient injection pressure, and improve material flow properties.

Molding Defects Sticking

- Cause: Part adhering to mold surface during ejection.

- Troubleshooting: Use mold release agents, adjust mold temperature, and optimize the ejection system.

Molding Defects Crystallization

- Cause: Rapid cooling leads to improper polymer crystalline structure.

- Troubleshooting: Adjust mold temperature, increase cooling time, and optimize melt temperature.

Molding Defects Crazing

- Cause: Incompatibility between material and mold release agents.

- Troubleshooting: Change mold release agents, ensure compatibility, and adjust ejection temperature.

Molding Defects Degradation

- Cause: Overheating of material during processing.

- Troubleshooting: Lower melt temperature, minimize residence time and improve material selection.

Mold Corrosion

- Cause: Chemical reactions between material and mold surfaces.

- Troubleshooting: Select corrosion-resistant mold materials, use mold coatings, and monitor processing conditions.

Mold Fouling

- Cause: Residue buildup on mold surfaces.

- Troubleshooting: Clean molds regularly, optimize material formulation, and use effective mold release agents.

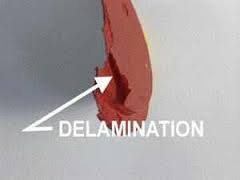

Molding Defects Delamination

- Cause: Poor bonding between layers in multi-material parts.

- Troubleshooting: Ensure material compatibility, optimize processing conditions, and adjust mold design.

Mold Pitting

- Cause: Physical or chemical erosion of mold surfaces.

- Troubleshooting: Use wear-resistant mold materials, maintain proper cooling, and apply protective coatings.

Molding Defects Jet Flow

- Cause: High-speed material flow causing surface defects.

- Troubleshooting: Reduce injection speed, adjust gate design, and optimize material viscosity.

Molding Defects Black Specks

- Cause: Contaminants or degraded material in the melt.

- Troubleshooting: Ensure material cleanliness, clean processing equipment, and use effective filtration systems.

Molding Defects Stringing

- Cause: Excessive material remaining attached after ejection.

- Troubleshooting: Optimize melt temperature, injection speed, and mold release mechanisms.

Molding Defects Gloss Variation

- Cause: Inconsistent cooling or mold surface issues.

- Troubleshooting: Optimize mold temperature, cooling channels, and apply mold surface treatments.

Molding Defects Undercuts

- Cause: Features preventing easy part ejection from the mold.

- Troubleshooting: Redesign part geometry to eliminate undercuts or use sliding cores.

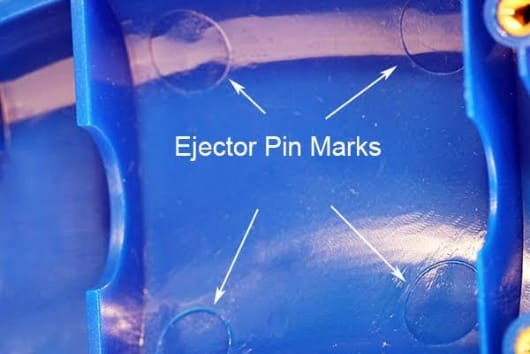

Molding Defects Ejector Marks

- Cause: Marks on the part due to ejection pins.

- Troubleshooting: Adjust ejection mechanisms, use smoother ejector pins, and optimize part ejection parameters.

Molding Defects Excessive Shrinkage

- Cause: Material composition or cooling issues causing high shrinkage.

- Troubleshooting: Adjust material formulation, optimize cooling rates, and control mold temperature.

Molding Defects Dimensional Inaccuracy

- Cause: Improper mold design or processing parameters.

- Troubleshooting: Ensure accurate mold design, optimize processing conditions, and control material properties.

Molding Defects Melt Fracture

- Cause: High shear rates causing material fracture.

- Troubleshooting: Lower injection speed, adjust gate design, and optimize material viscosity.

Molding Defects Jet Flow Lines

- Cause: High-speed material flow causing visible flow lines.

- Troubleshooting: Reduce injection speed, optimize gate design, and adjust melt temperature.

Parting Line Mismatch

- Cause: Misalignment of mold halves at the parting line.

- Troubleshooting: Ensure proper mold alignment, use shimming if necessary, and adjust clamping force.

Molding Defects Distortion

- Cause: Uneven cooling or internal stresses.

- Troubleshooting: Optimize cooling system, control mold temperature, and use proper ejection mechanisms.

Molding Defects Gas Burn Marks

- Cause: Gas trapped in the mold burning during injection.

- Troubleshooting: Improve mold venting, reduce injection speed, and ensure uniform melt flow.

Molding Defects Jet Flow

- Cause: Material velocity variations causing uneven surface finish.

- Troubleshooting: Optimize gate design, reduce injection speed, and adjust melt temperature.

Core Shift

- Cause: Movement of cores within the mold during injection.

- Troubleshooting: Improve core support, optimize molding parameters, and ensure proper clamping.

Mold Warpage

- Cause: Uneven mold cooling or inadequate support.

- Troubleshooting: Optimize cooling channels, control mold temperature, and use proper mold supports.

Mold Sticking

- Cause: Part adhering to the mold cavity.

- Troubleshooting: Use mold release agents, control mold temperature, and adjust ejection mechanisms.

Molding Defects Flow Imbalance

- Cause: Non-uniform material distribution in the mold cavity.

- Troubleshooting: Optimize gate design, adjust melt temperature, and ensure uniform injection pressure.

Molding Defects Vacuum Voids

- Cause: Vacuum forming within the mold cavity.

- Troubleshooting: Optimize venting, adjust injection speed, and reduce melt temperature.

Molding Defects Flow Restriction

- Cause: Constricted flow paths causing uneven material flow.

- Troubleshooting: Optimize gate design, increase gate size, and ensure uniform wall thickness.

Mold Erosion

- Cause: Abrasion or corrosion of mold surfaces.

- Troubleshooting: Use wear-resistant mold materials, optimize processing conditions, and apply protective coatings.

Molding Defects Cold Slugs

- Cause: Unmelted material entering the mold cavity.

- Troubleshooting: Increase melt temperature, optimize nozzle design, and ensure proper purging.

Molding Defects Contaminant Marks

- Cause: Foreign particles or contaminants in the melt.

- Troubleshooting: Use clean materials, implement proper material handling, and improve filtration.

Molding Defects Flow Lines

- Cause: Material flow disruptions causing visible lines.

- Troubleshooting: Optimize gate design, reduce injection speed, and adjust melt temperature.

Degassing Marks

- Cause: Gas escaping from the melt during injection.

- Troubleshooting: Optimize material drying, reduce melt temperature, and ensure proper venting.

Fiber Breakage

- Cause: Breakage of reinforcing fibers in composite materials.

- Troubleshooting: Optimize material formulation, ensure proper fiber orientation, and adjust processing parameters.

Excessive Flash

- Cause: Excessive material escaping from the mold cavity.

- Troubleshooting: Increase clamping force, optimize venting, and adjust injection pressure.

Gate Blush

- Cause: Material cooling prematurely at the gate.

- Troubleshooting: Optimize gate design, control mold temperature, and adjust injection parameters.

Addressing these molding defects requires a deep understanding of the underlying causes and a systematic approach to troubleshooting. Regular monitoring, process optimization, and collaboration between material scientists, mold designers, and processing engineers can help prevent or mitigate these defects effectively.

Conclusion

To sum up, molding defects can undermine the integrity and aesthetics of molded products. Their origins lie in intricate factors like material properties, mold design, and processing conditions. By diagnosing these causes accurately, manufacturers can implement targeted solutions such as adjusting temperatures, optimizing injection parameters, and enhancing mold design. This proactive approach, combined with regular monitoring and collaboration among experts, can effectively counter molding defects. Ultimately, this leads to improved product quality, reduced waste, and enhanced customer satisfaction.

FAQ’s

How can mold material defects be prevented?

Preventing mold material defects involves several key strategies –

Material Selection: Choose mold materials that match the intended production environment and the materials being molded. Consider factors such as temperature, pressure, chemical compatibility, and wear resistance.

Material Inspection: Thoroughly inspect mold materials for any defects or imperfections before use. This includes checking for cracks, voids, inclusions, or inconsistencies in the material’s composition.

Proper Heat Treatment: Ensure that the chosen mold material undergoes the appropriate heat treatment processes to achieve the desired hardness and structural integrity.

Quality Supplier: Source mold materials from reputable suppliers known for providing high-quality materials. This reduces the risk of using subpar or counterfeit materials.

Material Handling: Handle mold materials with care to prevent physical damage or contamination. Store them in controlled environments to avoid exposure to moisture, corrosive substances, or extreme temperatures.

Regular Maintenance: Implement a maintenance schedule to inspect and maintain molds over time. This includes cleaning, repairing, and, if necessary, reworking the mold surfaces.

Coatings and Treatments: Apply appropriate coatings or surface treatments to enhance the mold’s wear resistance, reduce friction, and improve its release properties.

Monitoring and Analysis: Regularly monitor the performance of molds during production. Analyze the molds for signs of wear, corrosion, or any emerging defects.

Corrective Action: If defects or wear are detected, take immediate corrective actions such as repairing, reconditioning, or replacing affected mold components.

Collaboration: Foster collaboration between mold designers, material suppliers, and processing engineers to ensure the chosen mold materials align with the intended manufacturing process and product requirements.

By following these preventive measures, manufacturers can significantly reduce the risk of mold material defects, resulting in improved product quality, extended mold life, and smoother production processes.

What are remedies for Compression Molding Defects?

Remedies for compression molding defects involve addressing specific issues to improve the quality and consistency of molded products –

Flash:

Optimize mold design for better parting line alignment.

Adjust clamp pressure to ensure proper mold closure.

Use proper mold release agents to prevent sticking.

Air Traps:

Enhance mold venting to allow trapped air to escape.

Adjust material temperature and injection speed for better flow.

Incomplete Fill:

Increase material temperature to ensure complete flow.

Optimize mold design to facilitate material distribution.

Warping:

Control mold temperature to ensure uniform cooling.

Optimize cooling system design for balanced cooling rates.

Cure Variations:

Monitor and adjust cure time and temperature for consistent results.

Use proper material mixing and preparation techniques.

Surface Defects:

Maintain cleanliness of mold surfaces and cavity.

Implement proper mold release agents and coatings.

Dimensional Inaccuracies:

Optimize material loading and distribution to avoid variations.

Use precision molds and calibrated equipment.

Blisters:

Adjust mold venting to prevent air entrapment.

Optimize material moisture content and processing conditions.

Void Formation:

Enhance material flow by adjusting temperature and pressure.

Use mold design that minimizes material trapping.

Brittleness:

Adjust cure time and temperature to optimize material properties.

Evaluate material formulation for improved flexibility.

Surface Finish Issues:

Implement proper mold polishing or texturing.

Use mold release agents and coatings for smoother finishes.

Delamination:

Ensure proper material compatibility in multi-layer molds.

Optimize bonding processes and mold design.

By addressing these remedies, manufacturers can mitigate compression molding defects and achieve consistent, high-quality molded products. Each remedy should be tailored to the specific defect and its underlying cause. Regular process monitoring and adjustments are key to successful defect prevention in compression molding.

How can you you improve the quality of injection molding?

Certainly, here are key points outlining how to improve the quality of injection molding –

Material Selection:

Choose materials with appropriate properties for the intended application.

Consider factors like flow characteristics, mechanical strength, and thermal stability.

Mold Design:

Design molds with proper gating, venting, and cooling systems.

Optimize part geometry for uniform filling and minimal stress concentration.

Mold Maintenance:

Regularly clean and maintain molds to prevent wear and buildup.

Address any signs of damage or degradation promptly.

Process Optimization:

Fine-tune injection parameters for optimal material flow and part formation.

Adjust melt temperature, injection speed, and pressure for consistent results.

Uniform Cooling:

Ensure uniform mold cooling to prevent warping and reduce cycle times.

Optimize cooling channels and use temperature control systems.

Quality Control Checks:

Implement rigorous quality checks throughout the production process.

Inspect parts for defects, dimensions, and surface finish.

Real-time Monitoring:

Utilize monitoring systems to track process variables and detect deviations.

Make immediate adjustments to maintain consistent quality.

Operator Training:

Train operators in proper machine operation, mold handling, and troubleshooting.

Knowledgeable operators can address issues effectively and ensure smooth production.

Material Handling:

Store and handle materials properly to prevent contamination and degradation.

Ensure proper drying of hygroscopic materials before molding.

Documentation and Traceability:

Maintain detailed records of process parameters, materials used, and production conditions.

Establish traceability to quickly identify and rectify any quality issues.

Continuous Improvement:

Regularly analyze data and feedback to identify trends and areas for improvement.

Implement changes and innovations to enhance quality over time.

By focusing on these aspects, manufacturers can enhance the quality of their injection molding processes, leading to better product performance, reduced defects, and improved customer satisfaction.

Saved as a favorite, I really like your web site!

It’s a pity you don’t have a donate button! I’d without a doubt donate to this superb

blog! I guess for now i’ll settle for book-marking and

adding your RSS feed to my Google account. I look forward to fresh updates and will share this blog with my Facebook group.

Chat soon!

Thank you so much for your kind words and support — it truly means a lot! 😊

I’m honored that you find the blog valuable enough to consider donating. While there’s no donate button at the moment, your gesture of bookmarking, subscribing to the RSS feed, and sharing it with your Facebook group is more than appreciated.

Stay tuned for more updates — and feel free to reach out anytime at https://autoplasticsworld.com/about-us/

Its such as you read my thoughts! You appear to grasp so much approximately this, like you wrote the book in it or something.

I feel that you simply could do with a few % to power the message house a little

bit, but other than that, this is magnificent blog.

A fantastic read. I’ll certainly be back.

Sure

Hey there! I’ve been following your blog for a long time now and finally got the bravery to go ahead and give you a

shout out from Porter Texas! Just wanted to say keep up the

fantastic work!

Thanks dear

Fantastic website you have here but I was wanting to know if you knew of any discussion boards that cover

the same topics discussed in this article?

I’d really like to be a part of group where I can get comments from other knowledgeable individuals that share

the same interest. If you have any suggestions, please let me know.

Kudos!

Hello there! This post couldn’t be written any better! Reading this post reminds

me of my good old room mate! He always kept chatting about

this. I will forward this page to him. Fairly certain he will have a good read.

Many thanks for sharing!

Now I am feeling so proud of my writing skill that you guys are loving in such a way…

I’ve been browsing online greater than three hours nowadays,

yet I never discovered any attention-grabbing article like yours.

It’s lovely price sufficient for me. In my opinion, if all web owners and bloggers made just right content as

you probably did, the net will probably be much more useful than ever before.

continuously i used to read smaller articles that as well clear their motive, and

that is also happening with this piece of writing which I am reading at this place.

Good

I am actually happy to glance at this website posts which includes lots of helpful facts, thanks for providing such information.

When I originally commented I clicked the “Notify me when new comments are added”

checkbox and now each time a comment is added I

get several e-mails with the same comment. Is

there any way you can remove people from that service?

Bless you!

sure

It’s very easy to find out any topic on web as compared to books, as

I found this paragraph at this website.

Hi i am kavin, its my first time to commenting anyplace, when i read this

post i thought i could also create comment due to this sensible post.

I gotta bookmark this site it seems very helpful extremely helpful

Hi terrific website! Does running a blog such as this take a large amount of work?

I’ve no knowledge of computer programming but I was hoping to start my own blog in the

near future. Anyhow, if you have any ideas or techniques for new blog

owners please share. I know this is off topic however I just needed to ask.

Thanks a lot!

If you are going for best contents like myself, only go to see this web site everyday since

it gives quality contents, thanks

We absolutely love your blog and find a lot of your post’s to be

exactly what I’m looking for. can you offer guest writers to write content

for yourself? I wouldn’t mind writing a post or elaborating on a number

of the subjects you write in relation to here. Again, awesome weblog!

As a Newbie, I am continuously searching online for articles that can benefit me. Thank you

F*ckin’ remarkable things here. I am very glad to peer your post. Thanks so much and i am taking a look forward to contact you. Will you please drop me a mail?

Yes! Finally someone writes about subur88.

Ahaa, its nice dialogue on the topic of this article at this place at this blog,

I have read all that, so at this time me also commenting here.

I like this blog so much, saved to bookmarks. “To hold a pen is to be at war.” by Francois Marie Arouet Voltaire.

Good V I should definitely pronounce, impressed with your website. I had no trouble navigating through all tabs and related information ended up being truly simple to do to access. I recently found what I hoped for before you know it in the least. Quite unusual. Is likely to appreciate it for those who add forums or something, site theme . a tones way for your customer to communicate. Excellent task..

Wow! Thank you! I constantly wanted to write on my site something like that. Can I implement a part of your post to my blog?

I am not sure where you are getting your information, but great topic. I needs to spend some time learning more or understanding more. Thanks for excellent info I was looking for this info for my mission.

I conceive this internet site holds some real fantastic info for everyone : D.

I went over this web site and I conceive you have a lot of wonderful information, saved to fav (:.

Very interesting information!Perfect just what I was searching for!

I loved as much as you will receive carried out right here. The sketch is tasteful, your authored subject matter stylish. nonetheless, you command get got an impatience over that you wish be delivering the following. unwell unquestionably come further formerly again since exactly the same nearly a lot often inside case you shield this hike.

It’s actually a great and helpful piece of information. I’m glad that you shared this useful info with us. Please keep us up to date like this. Thanks for sharing.

Oh my goodness! an amazing article dude. Thanks Nevertheless I’m experiencing issue with ur rss . Don’t know why Unable to subscribe to it. Is there anyone getting similar rss drawback? Anybody who is aware of kindly respond. Thnkx

I will right away grab your rss feed as I can not find your email subscription link or newsletter service. Do you’ve any? Kindly let me know in order that I could subscribe. Thanks.

I have been checking out a few of your posts and i can state pretty clever stuff. I will make sure to bookmark your blog.

Yeah bookmaking this wasn’t a high risk conclusion great post! .

naturally like your website but you need to take a look at the spelling on quite a few of your posts. A number of them are rife with spelling issues and I to find it very bothersome to tell the truth nevertheless I’ll certainly come again again.

Lovely just what I was looking for.Thanks to the author for taking his time on this one.

Wow, fantastic blog layout! How long have you been blogging for? you make blogging look easy. The overall look of your web site is excellent, as well as the content!

from last 3 years, but as a part time

Hello. remarkable job. I did not anticipate this. This is a great story. Thanks!

It’s really a nice and useful piece of info. I’m satisfied that you shared this helpful information with us. Please keep us up to date like this. Thank you for sharing.

Rattling clear web site, appreciate it for this post.

I have been checking out a few of your posts and it’s pretty nice stuff. I will definitely bookmark your site.

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!

My brother recommended I might like this blog. He was entirely right. This post truly made my day. You cann’t imagine simply how much time I had spent for this info! Thanks!

I like this web site because so much useful stuff on here : D.

I like what you guys are up too. Such intelligent work and reporting! Keep up the excellent works guys I’ve incorporated you guys to my blogroll. I think it’ll improve the value of my website :).

I was just searching for this information for a while. After 6 hours of continuous Googleing, at last I got it in your web site. I wonder what is the lack of Google strategy that do not rank this type of informative websites in top of the list. Usually the top sites are full of garbage.

Of course, what a splendid website and informative posts, I surely will bookmark your website.All the Best!

My brother suggested I might like this website. He was entirely right. This post truly made my day. You can not imagine simply how much time I had spent for this information! Thanks!

It is really a great and helpful piece of info. I’m glad that you shared this helpful info with us. Please keep us informed like this. Thanks for sharing.

I like what you guys are up too. Such intelligent work and reporting! Carry on the excellent works guys I have incorporated you guys to my blogroll. I think it will improve the value of my web site 🙂

Very interesting subject, thanks for posting.

Some genuinely terrific work on behalf of the owner of this site, utterly great content.

Really nice style and design and wonderful articles, absolutely nothing else we want : D.

I always was concerned in this subject and still am, thanks for putting up.

Excellent post. I used to be checking continuously this blog and I am inspired! Very useful info specially the closing section 🙂 I deal with such information much. I was seeking this particular info for a long time. Thank you and best of luck.

I went over this web site and I conceive you have a lot of excellent info, saved to favorites (:.

Please let me know if you’re looking for a writer for your blog. You have some really great articles and I feel I would be a good asset. If you ever want to take some of the load off, I’d love to write some articles for your blog in exchange for a link back to mine. Please blast me an email if interested. Cheers!

You can certainly see your expertise within the work you write. The arena hopes for more passionate writers such as you who aren’t afraid to mention how they believe. At all times go after your heart. “Experience is a good school, but the fees are high.” by Heinrich Heine.

Very nice post. I just stumbled upon your weblog and wished to say that I have really enjoyed surfing around your blog posts. After all I will be subscribing to your rss feed and I hope you write again soon!

excellent put up, very informative. I wonder why the other specialists of this sector do not understand this. You must proceed your writing. I’m confident, you have a great readers’ base already!

What’s Happening i’m new to this, I stumbled upon this I’ve discovered It absolutely helpful and it has aided me out loads. I am hoping to give a contribution & help other users like its aided me. Good job.

Asking questions are in fact good thing if you are not understanding something totally, however this article

gives fastidious understanding even.

Hello.This article was extremely fascinating, particularly because I was investigating for thoughts on this subject last week.

An interesting discussion is worth comment. I think that you should write more on this topic, it might not be a taboo subject but generally people are not enough to speak on such topics. To the next. Cheers

Woh I enjoy your content, bookmarked! .

Thank you for every other magnificent article. The place else could anyone get that kind of information in such a perfect approach of writing? I have a presentation next week, and I am on the look for such info.

Some genuinely excellent information, Glad I noticed this. “Childhood is that wonderful time when all you need to do to lose weight is take a bath.” by Joe Moore.

Keep functioning ,impressive job!

Somebody essentially help to make seriously posts I would state. This is the very first time I frequented your website page and thus far? I surprised with the research you made to create this particular publish extraordinary. Wonderful job!

Someone essentially help to make seriously posts I would state. This is the very first time I frequented your website page and thus far? I surprised with the research you made to create this particular publish amazing. Great job!

I like what you guys are up also. Such clever work and reporting! Carry on the excellent works guys I?¦ve incorporated you guys to my blogroll. I think it’ll improve the value of my website 🙂

Hiya, I am really glad I’ve found this information. Nowadays bloggers publish only about gossips and internet and this is actually annoying. A good blog with interesting content, that’s what I need. Thank you for keeping this web site, I’ll be visiting it. Do you do newsletters? Cant find it.

not rightnow

Excellent read, I just passed this onto a colleague who was doing a little research on that. And he just bought me lunch as I found it for him smile Thus let me rephrase that: Thank you for lunch! “A human being has a natural desire to have more of a good thing than he needs.” by Mark Twain.

I appreciate your work, thanks for all the useful posts.

Once I originally commented I clicked the -Notify me when new comments are added- checkbox and now each time a remark is added I get 4 emails with the same comment. Is there any method you can remove me from that service? Thanks!

Hello There. I found your blog using msn. This is a very well written article. I will make sure to bookmark it and return to read more of your useful information. Thanks for the post. I’ll definitely comeback.

I really like your writing style, fantastic information, regards for posting :D. “God save me from my friends. I can protect myself from my enemies.” by Claude Louis Hector de Villars.

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.

Hi, Neat post. There’s a problem with your site in internet explorer, would check this… IE still is the market leader and a large portion of people will miss your magnificent writing due to this problem.

Hi there, I found your web site by way of Google even as searching for a similar matter, your website came up, it appears to be like great. I’ve bookmarked it in my google bookmarks.

Very interesting points you have mentioned, appreciate it for posting.

I take pleasure in, cause I discovered just what I used to be looking for. You have ended my four day long hunt! God Bless you man. Have a nice day. Bye

I cherished as much as you will receive carried out right here. The sketch is tasteful, your authored subject matter stylish. nonetheless, you command get got an edginess over that you want be delivering the following. in poor health indubitably come more formerly again since precisely the similar just about a lot ceaselessly within case you protect this hike.

As a Newbie, I am permanently searching online for articles that can aid me. Thank you

Thanks for the sensible critique. Me and my neighbor were just preparing to do some research on this. We got a grab a book from our area library but I think I learned more clear from this post. I’m very glad to see such wonderful information being shared freely out there.

I want reading and I think this website got some genuinely useful stuff on it! .

Good info. Lucky me I reach on your website by accident, I bookmarked it.

Hi there! This post couldn’t be written any better! Reading through this post reminds me of my previous room mate! He always kept talking about this. I will forward this article to him. Pretty sure he will have a good read. Thank you for sharing!

It’s exhausting to search out educated people on this topic, however you sound like you understand what you’re talking about! Thanks

Hi, just required you to know I he added your site to my Google bookmarks due to your layout. But seriously, I believe your internet site has 1 in the freshest theme I??ve came across. It extremely helps make reading your blog significantly easier.

I conceive you have noted some very interesting details, appreciate it for the post.

Hiya, I’m really glad I’ve found this information. Nowadays bloggers publish just about gossips and internet and this is really frustrating. A good site with interesting content, that is what I need. Thanks for keeping this site, I’ll be visiting it. Do you do newsletters? Cant find it.

I think this internet site holds some rattling excellent information for everyone : D.

Of course, what a magnificent website and educative posts, I definitely will bookmark your site.Have an awsome day!

It’s really a nice and useful piece of information. I am glad that you shared this helpful information with us. Please keep us informed like this. Thanks for sharing.

Great work! This is the type of information that should be shared around the net. Shame on Google for not positioning this post higher! Come on over and visit my site . Thanks =)

I am no longer positive where you are getting your info, but great topic. I needs to spend some time finding out more or working out more. Thanks for excellent info I was in search of this info for my mission.

This web site can be a stroll-by way of for all of the info you wished about this and didn’t know who to ask. Glimpse here, and also you’ll positively discover it.

You can certainly see your enthusiasm within the paintings you write. The world hopes for more passionate writers like you who are not afraid to say how they believe. Always follow your heart. “We are near waking when we dream we are dreaming.” by Friedrich von Hardenberg Novalis.

Your article helped me a lot, is there any more related content? Thanks!

It¦s really a nice and helpful piece of info. I am satisfied that you just shared this useful info with us. Please stay us up to date like this. Thank you for sharing.

I have been absent for some time, but now I remember why I used to love this blog. Thank you, I?¦ll try and check back more frequently. How frequently you update your web site?

It’s really a nice and helpful piece of information. I am glad that you shared this useful info with us. Please keep us informed like this. Thanks for sharing.

Saved as a favorite, I really like your blog!

hello there and thank you for your info – I have definitely picked up anything new from right here. I did however expertise a few technical issues using this web site, as I experienced to reload the website a lot of times previous to I could get it to load correctly. I had been wondering if your web hosting is OK? Not that I’m complaining, but slow loading instances times will often affect your placement in google and could damage your high-quality score if ads and marketing with Adwords. Anyway I’m adding this RSS to my e-mail and can look out for much more of your respective intriguing content. Make sure you update this again very soon..

Hi! Do you use Twitter? I’d like to follow you if that would be okay. I’m absolutely enjoying your blog and look forward to new posts.

Can I just say what a relief to find someone who actually knows what theyre talking about on the internet. You definitely know how to bring an issue to light and make it important. More people need to read this and understand this side of the story. I cant believe youre not more popular because you definitely have the gift.

Hiya, I’m really glad I have found this info. Today bloggers publish just about gossips and internet and this is actually annoying. A good website with exciting content, that is what I need. Thanks for keeping this web-site, I’ll be visiting it. Do you do newsletters? Can’t find it.

I have recently started a website, the info you offer on this site has helped me tremendously. Thank you for all of your time & work. “There is a time for many words, and there is also a time for sleep.” by Homer.

I relish, cause I found just what I used to be taking a look for. You have ended my four day long hunt! God Bless you man. Have a nice day. Bye

Thanks for some other informative web site. The place else may just I am getting that kind of info written in such a perfect way? I have a challenge that I am simply now working on, and I’ve been on the glance out for such info.

The very crux of your writing whilst appearing agreeable in the beginning, did not work very well with me personally after some time. Someplace within the sentences you managed to make me a believer unfortunately only for a very short while. I nevertheless have got a problem with your leaps in assumptions and one might do well to help fill in those gaps. In the event that you actually can accomplish that, I will definitely be amazed.

Everything is very open and very clear explanation of issues. was truly information. Your website is very useful. Thanks for sharing.

Wow! After all I got a web site from where I can truly get helpful data

concerning my study and knowledge.

excellent points altogether, you simply gained a new reader. What might you recommend in regards to your post that you simply made some days in the past? Any positive?

This is the precise blog for anyone who needs to seek out out about this topic. You notice a lot its virtually hard to argue with you (not that I actually would need…HaHa). You undoubtedly put a brand new spin on a subject thats been written about for years. Nice stuff, simply nice!

Spot on with this write-up, I truly think this web site needs rather more consideration. I’ll in all probability be again to read way more, thanks for that info.

I got what you intend, thankyou for posting.Woh I am glad to find this website through google.