Definition of Eye Bolt

An eye bolt is a type of mechanical fastener that has a ring or “eye” at one end and a threaded shaft at the other. The eye is used for attaching ropes, chains, or hooks, while the threaded part is used to screw into the object you want to lift — such as a mould in injection molding machines.

In simple terms, it acts like a handle that helps in lifting and moving heavy tools or components safely using cranes or hoists.

Importance of Eye Bolt

Eye bolts play a very important role in mould handling and safety. Here’s why:

- Lifting and Shifting: Moulds are heavy. Eye bolts allow moulds to be lifted safely using slings and cranes.

- Machine Maintenance: During mould changing or maintenance, eye bolts help in easy dismounting.

- Safety: Proper eye bolts reduce the risk of mould drop accidents.

- Load Distribution: Eye bolts help distribute weight evenly.

- Time Saving: Helps in faster lifting, mounting, and transporting.

If the wrong type or damaged eye bolt is used, it can lead to accidents, including mould damage, machine injury, and even human harm.

Weight Capacity Calculation for Eye Bolt (M8 to M64)

| Eye Bolt Size | Safe Load (kg) – Vertical | Safe Load (kg) – 45° Angle | Safe Load (kg) – 90° Angle |

| M8 | 140 | 70 | 35 |

| M10 | 230 | 115 | 55 |

| M12 | 340 | 170 | 85 |

| M16 | 700 | 350 | 175 |

| M20 | 1200 | 600 | 300 |

| M24 | 1800 | 900 | 450 |

| M30 | 3200 | 1600 | 800 |

| M36 | 5000 | 2500 | 1250 |

| M42 | 8000 | 4000 | 2000 |

| M48 | 10000 | 5000 | 2500 |

| M56 | 16000 | 8000 | 4000 |

| M64 | 20000 | 10000 | 5000 |

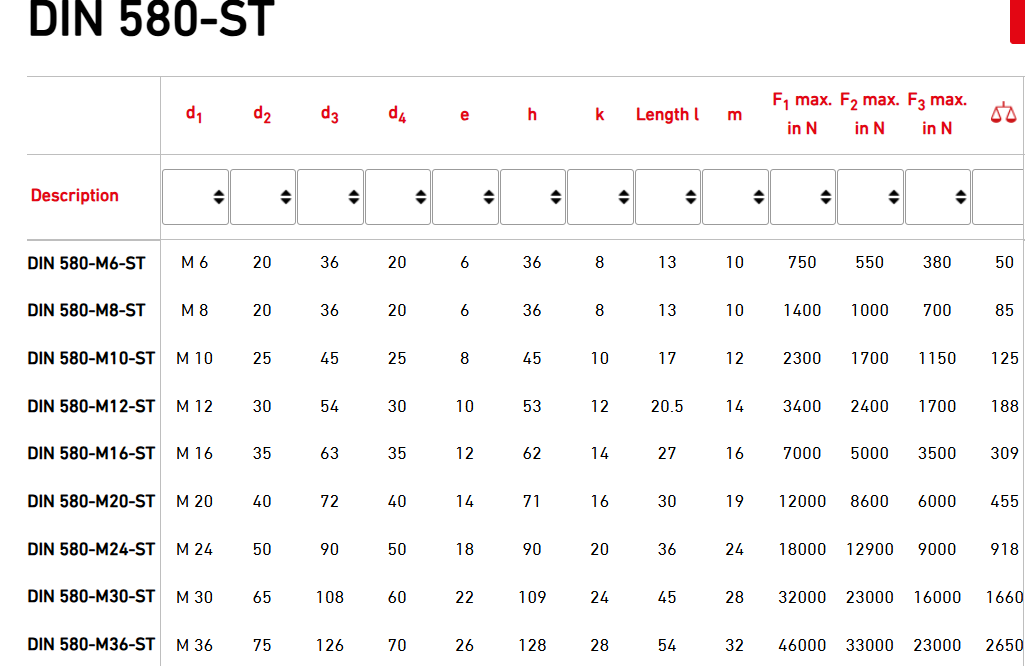

Note: Values may vary by manufacturer. Always refer to load charts and standards like DIN 580.

DIN 580-ST Eye Bolt Standard

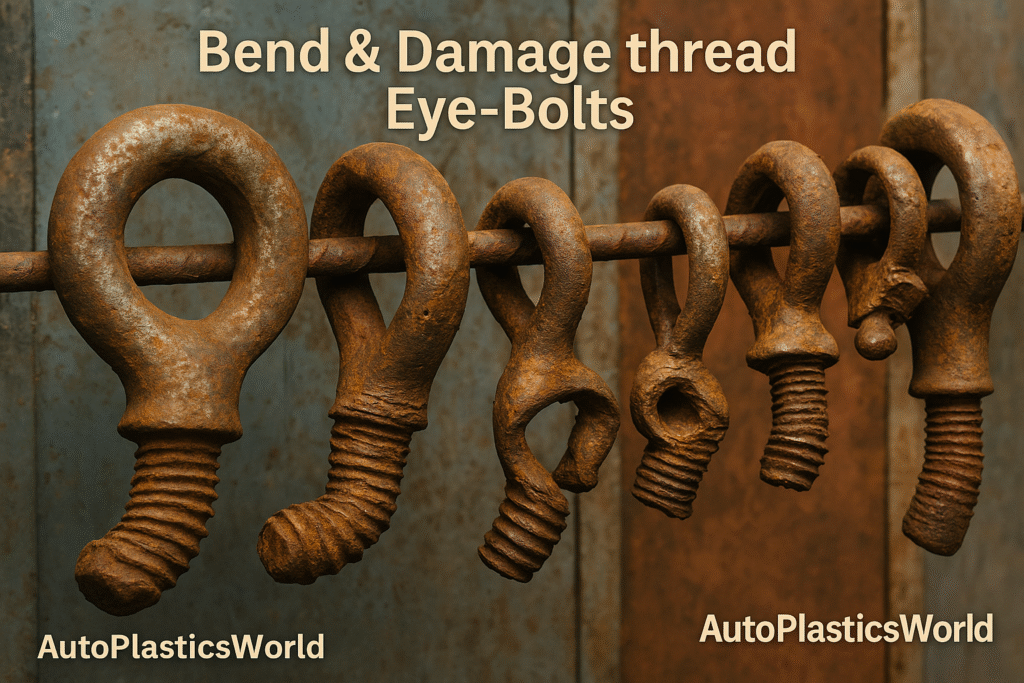

When Eye Bolt Should Not Be Used (Damage Criteria)

Check if any of the following conditions exist:

- Bent Eye Bolt: Even a 5° bend is unsafe.

- Thread Damage: If threads are worn, stripped, or broken, do not reuse.

- Corrosion/Rust: Red or flaky rust indicates weakening metal.

- Crack in Eye Ring: Any visible crack = immediate rejection.

- Eye Bolt Life Over: If the bolt has crossed its recommended load cycles.

- Deformation of Eye Loop: Any widening or oval shape means damage.

- Loose Fitting in Mould: If eye bolt doesn’t sit tight in the mould.

- Unknown History: If records are missing, do not use it on critical loads.

Preparation Before Fitting Eye Bolt

Before using any eye bolt on moulds:

- ✅ Check thread condition of mould where eye bolt will be fixed.

- ✅ Ensure eye bolt is fully tightened to the mould base — no gap.

- ✅ Choose the correct size and length of thread.

- ✅ Check lifting capacity of that eye bolt size.

- ✅ Verify mould weight before using.

- ✅ Use only certified and marked eye bolts (e.g., DIN 580).

- ✅ Check both sling and crane load rating.

- ✅ Inspect for cracks, bends, rust, or wear.

- ✅ Never use homemade or altered eye bolts.

- ✅ Confirm angle of lift (straight = safest).

Do’s and Don’ts of Eye Bolt

✅ Do’s

- Use proper size bolt for mould weight.

- Use flat washer if surface is uneven.

- Tighten completely before lifting.

- Use slings of equal length.

- Always lift vertically if possible.

- Use proper crane signals during lifting.

❌ Don’ts

- Don’t use damaged or bent eye bolts.

- Don’t lift mould if bolt is loose or tilted.

- Don’t over-tighten to avoid thread damage.

- Don’t use eye bolt in cracked mould base.

- Don’t exceed the rated load.

- Don’t use open hooks on eye bolts.

- Don’t reuse old bolts without inspection.

- Don’t apply side loads unless the bolt is rated for it.

MCQ on Eye Bolt Safety in Injection Molding

What is the main function of an eye bolt?

- a) To hold sensors

- b) To lift heavy parts like moulds

- c) To cool the mould

- d) To store moulds

Answer: b

What happens if an eye bolt is bend?

- a) It becomes stronger

- b) It’s safe if angle is small

- c) It must be rejected

- d) It improves lifting

- Answer: c

Eye bolts should be:

- a) Painted

- b) Partially threaded

- c) Fully tightened

- d) Loose for adjustment

- Answer: c

Before fitting an eye bolt, which of the following is most important?

- a) Colour check

- b) Crack in mould

- c) Thread condition

- d) Use any size

- Answer: c

Eye bolt fitting must not have:

- a) Tight threads

- b) Flat washer

- c) Gap between base

- d) Rust-free surface

- Answer: c

When lifting with eye bolts, always:

- a) Pull from the side

- b) Hang uneven load

- c) Use equal sling lengths

- d) Shake the mould

- Answer: c

Thread damage is acceptable up to:

- a) 2 threads

- b) 50% thread loss

- c) No damage is acceptable

- d) After 10 uses

- Answer: c

Corrosion on eye bolt means:

- a) Extra strength

- b) Safe to use

- c) Weakening metal

- d) Looks old but strong

- Answer: c

A locating ring on the mold helps in:

- a) Lifting

- b) Injection alignment

- c) Heating

- d) Thread cleaning

- Answer: b

Sprue bush helps:

- a) Clamping

- b) Injection material entry

- c) Eye bolt fitting

- d) Mould cooling

- Answer: b

For overhead crane lifting, eye bolts must be:

- a) Tightly hammered

- b) Certified and inspected

- c) Home made

- d) Lightweight

- Answer: b

Eye bolt should be changed if:

- a) Rust is light

- b) Threads are new

- c) Eye ring is bent

- d) Used only once

- Answer: c

What to do before lifting a mold?

- a) Start crane first

- b) Check eye bolts and threads

- c) Paint eye bolts

- d) Fit ejector pin

- Answer: b

If mold tilts slightly during lift:

- a) Stop lift and check bolts

- b) Pull harder

- c) Add more oil

- d) Ignore

- Answer: a

Conclusion

Eye bolts are small but very important parts in injection mould handling. A simple negligence like not checking the gap or using a bent bolt can cause huge damage. Always follow proper inspection, fitting, and lifting practices. Use only standard eye bolts and regularly train your team on safety measures.

By following the above guidance, we can prevent many workplace injuries and machine breakdowns in the injection molding industry.

To connect directly with admin of this site, you can follow him on Instagram, LinkedIn

Thanks for sharing excellent informations. Your web site is very cool. I’m impressed by the details that you have on this website. It reveals how nicely you perceive this subject. Bookmarked this web page, will come back for more articles. You, my pal, ROCK! I found simply the information I already searched everywhere and just couldn’t come across. What a great website.

Thank you for sharing superb informations. Your web site is very cool. I am impressed by the details that you’ve on this web site. It reveals how nicely you perceive this subject. Bookmarked this website page, will come back for extra articles. You, my pal, ROCK! I found just the information I already searched everywhere and just couldn’t come across. What a great web-site.

I was reading through some of your posts on this site and I think this website is real instructive! Keep putting up.

Smooth and clear

I happen to be writing to let you understand what a exceptional discovery my friend’s girl found studying your blog. She picked up many details, most notably what it’s like to have a wonderful coaching nature to make the others just learn about specified problematic topics. You actually did more than my expectations. Thanks for supplying such beneficial, healthy, revealing and in addition cool tips about the topic to Janet.