Ethylene Propylene Diene Monomer (EPDM) is a synthetic rubber widely used in automotive, construction, electrical, and industrial applications.

- EPDM combines excellent weather resistance, flexibility, and durability, making it a preferred choice for molded components. Transfer molding, being precise and suitable for high-volume production, enhances the utility of EPDM.

Definition of EPDM

- Full form: Ethylene Propylene Diene Monomer.

- Definition:

EPDM is a terpolymer made from ethylene, propylene, and a small amount of non-conjugated diene monomers. - Key property: The saturated polymer backbone provides resistance against heat, oxidation, ozone, and weathering, unlike natural rubber.

- Nature:

- Amorphous or semi-crystalline.

- Cross-linked during vulcanization to achieve desired elasticity.

- Relation to transfer molding: EPDM compounds can be pre-formed and molded under pressure into complex shapes with excellent dimensional stability.

Chemical Composition of EPDM

Main ingredients:

- Ethylene (45–75%) – Provides crystallinity and tensile strength.

- Propylene (25–55%) – Adds flexibility and processability.

- Diene (2–12%) – Provides unsaturation sites for sulfur or peroxide vulcanization. Common dienes:

- Ethylidene Norbornene (ENB) – Most widely used.

- Dicyclopentadiene (DCPD).

- Vinyl Norbornene (VNB).

Additives in EPDM compounds:

- Fillers (Carbon black, silica, CaCO₃).

- Plasticizers (paraffinic/naphthenic oils).

- Processing aids.

- Cross-linking agents (Sulfur, Peroxides).

- Accelerators (MBT, CBS).

- Anti-oxidants and anti-ozonants.

Manufacturing Process of EPDM Material

Step 1: Polymerization

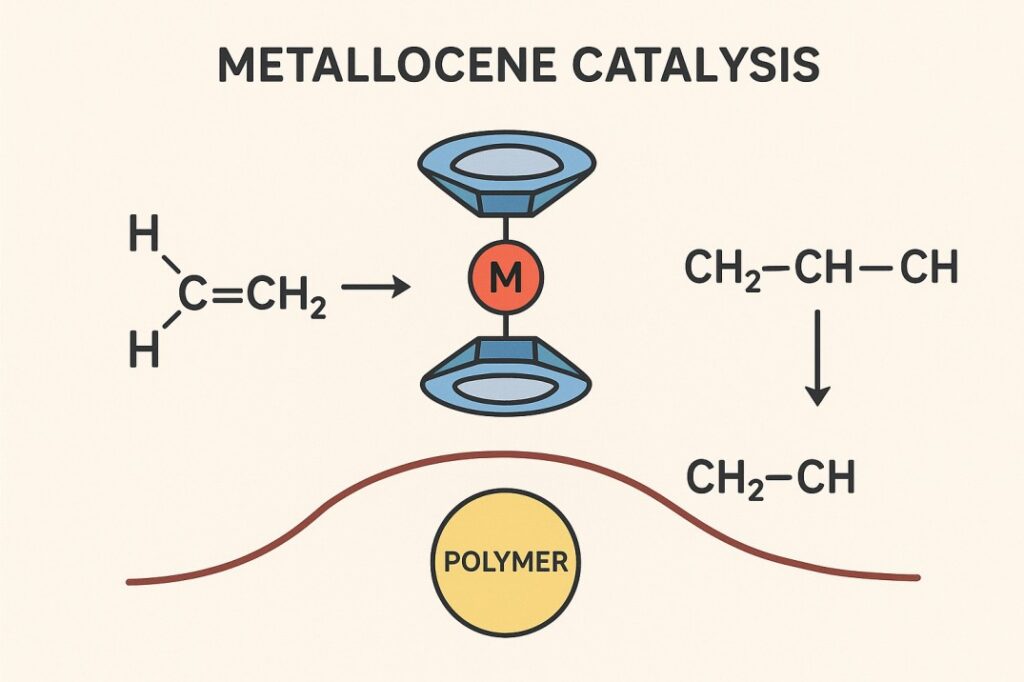

- EPDM is produced by Ziegler–Natta catalysis or metallocene catalysis.

- Ethylene, propylene, and diene are polymerized in a solution or gas phase.

Step 2: Recovery

- Polymer slurry is separated from the catalyst and solvent.

- Residual catalyst is deactivated and removed.

Step 3: Finishing

- Polymer is dried, pelletized, and packaged for shipment.

Step 4: Compounding

- Raw EPDM gum is blended with fillers, plasticizers, and curing agents.

- Banbury mixers or two-roll mills are used.

Step 5: Pre-forming

- Compound is sheeted or pelletized for use in molding operations.

Shelf Life of EPDM

Uncured EPDM compound:

- Shelf life: 6–12 months if stored below 25°C and away from direct sunlight.

- Susceptible to premature vulcanization if improperly stored.

Cured EPDM products:

- Shelf life: 5–15 years depending on formulation.

- Resistant to ozone, UV, and weathering, giving long service life in outdoor applications.

Storage guidelines:

- Store in cool, dark, dry conditions.

- Avoid exposure to copper, manganese, or other curing-sensitive metals.

Properties of EPDM

Mechanical Properties

- Tensile Strength: 7–21 MPa (depending on formulation).

- Elongation at break: 300–600%.

- Hardness: 30–90 Shore A.

Thermal Properties

- Service temperature range: –50°C to +150°C (peroxide cured EPDM can withstand up to 180°C).

Chemical Resistance

- Excellent resistance to:

- Water, steam.

- Alkalis, acids (dilute).

- Polar solvents (alcohols, ketones).

- Poor resistance to:

- Hydrocarbons (oils, fuels).

- Aromatic and halogenated solvents.

Electrical Properties

- Excellent insulation.

- Used in high-voltage cable insulation.

Weathering Properties

- Resistant to ozone cracking, UV degradation, and aging.

Transfer Molding Process for EPDM

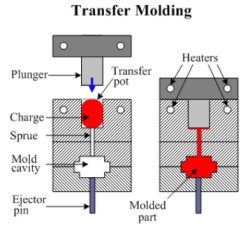

Step 1: Pre-form Preparation

- EPDM compound is pre-mixed and formed into slugs or pellets.

- Preforms must match the cavity volume to reduce wastage.

- Compression density: 1.2–1.4 g/cm³ depending on filler content.

Step 2: Loading into Transfer Pot

- Preform is placed into the transfer pot of the molding press.

- Pot is heated to soften EPDM before injection.

Step 3: Transfer to Cavities

- A plunger pushes softened EPDM into runner channels.

- Material flows into cavities under pressure (20–70 MPa).

Step 4: Vulcanization

- Molds are heated (170–200°C).

- Vulcanization occurs inside the mold cavity.

- Time cycle: 2–10 minutes depending on part thickness.

Step 5: Demolding

- Mold opens, ejector pins release the cured EPDM part.

- Flash is trimmed manually or automatically.

Step 6: Post-Curing (Optional)

- For peroxide-cured EPDM: post-curing at 150–200°C improves thermal stability.

EPDM vs Other Rubbers

| Property | EPDM | NBR (Nitrile) | SBR (Styrene-Butadiene) | Silicone (VMQ) | FKM (Viton) | NR (Natural Rubber) |

|---|---|---|---|---|---|---|

| Oil Resistance | Poor | Excellent | Poor | Moderate | Excellent | Poor |

| Weather Resistance | Excellent | Fair | Poor | Excellent | Excellent | Poor |

| Temp. Range | –50°C to 150°C | –30°C to 120°C | –40°C to 100°C | –60°C to 230°C | –20°C to 250°C | –50°C to 80°C |

| Ozone Resistance | Excellent | Poor | Poor | Excellent | Excellent | Poor |

| Cost | Low | Medium | Low | High | Very High | Low |

| Common Use | Seals, roofs, cables | Fuel hoses, gaskets | Tires | Medical, food | Aerospace, fuel systems | Tires, general rubber goods |

Advantages & Limitations of Transfer Molding with EPDM

Advantages:

- Produces complex shapes with inserts (e.g., metal-rubber bonded seals).

- Better dimensional accuracy than compression molding.

- Faster cycle times than compression.

- Suitable for medium to high volume production.

Limitations:

- More material wastage than injection molding (flash & transfer pad).

- Higher tooling cost compared to compression molding.

Application Areas of EPDM in Transfer Molding

Automotive Industry

- Door seals, weatherstrips, gaskets.

- Radiator hoses, brake components.

- Wire & cable insulation.

Construction Industry

- Roofing membranes.

- Window and door seals.

- Expansion joints.

Electrical & Electronics

- Cable jacketing.

- High-voltage insulation parts.

Industrial Applications

- O-rings, gaskets.

- Vibration dampers.

- Conveyor belts.

Consumer Goods

- Household appliance seals.

- Sports equipment grips.

Detailed EPDM Manufacturing & Compounding

1 Polymerization Techniques

- Solution Polymerization (most common): Hydrocarbon solvent, Ziegler-Natta catalyst.

- Slurry Process: Ethylene-propylene polymerization in hexane, then diene addition.

- Gas-Phase Polymerization: Advanced, eco-friendly, eliminates solvents.

2 Catalysts Used

- Ziegler-Natta (TiCl₄ + AlEt₃).

- Metallocene catalysts (better control of molecular weight).

3 Compounding Recipe Example (Automotive Seal)

- 100 phr EPDM gum.

- 80 phr Carbon black N550.

- 40 phr Paraffinic oil.

- 5 phr ZnO (activator).

- 1 phr Stearic acid.

- 2 phr Sulfur (crosslinking).

- 1.5 phr MBT accelerator.

- 1 phr TMQ antioxidant.

phr = parts per hundred rubber.

4 Key Factors in Compounding

- Ethylene content (low = flexible, high = stiff).

- Diene type (ENB gives faster cure rate).

- Filler loading controls hardness, strength, cost.

Pros and Cons of EPDM

Pros

- Excellent weather and ozone resistance.

- Long service life.

- Flexible at low temperatures.

- Good electrical insulation.

- Cost-effective compared to fluorocarbon rubbers.

- Compatible with peroxide curing for high-temperature stability.

Cons

- Poor resistance to petroleum-based oils and fuels.

- Lower tensile strength compared to some rubbers (e.g., NBR, FKM).

- Cannot be used in applications with direct hydrocarbon exposure.

- Processing challenges: requires precise mixing and vulcanization.

Conclusion

- EPDM is best for weather, ozone, and outdoor applications.

- It is not suitable for oil/fuel environments (NBR/FKM are better).

- Silicone beats EPDM in extreme high/low temperatures but at higher cost.

FAQ

What does EPDM stand for?

Ethylene Propylene Diene Monomer.

Is EPDM natural or synthetic rubber?

EPDM is a synthetic rubber.

Why is diene added in EPDM?

Diene provides unsaturation sites for vulcanization.

What is the typical hardness range of EPDM?

30–90 Shore A.

Can EPDM withstand oil and fuel?

No, EPDM has poor oil and fuel resistance.

What is the temperature range of EPDM?

–50°C to +150°C (up to 180°C with peroxide curing).

How long does EPDM last outdoors?

10–20 years depending on conditions.

Can EPDM be used for potable water applications?

Yes, with proper formulation and certification.

Is EPDM recyclable?

Yes, via mechanical and chemical recycling methods.

Why is EPDM used in roofing membranes?

Because of its excellent UV and weather resistance.

What is the difference between EPDM and NBR?

EPDM resists weathering but not oil; NBR resists oil but not weathering.

Can EPDM be colored?

Yes, pigments can be added during compounding.

Which curing system is better for EPDM – sulfur or peroxide?

Peroxide curing offers better heat resistance; sulfur is more economical.

Does EPDM absorb water?

Very low water absorption (<0.1%).

Is EPDM suitable for medical applications?

Not typically, but can be modified for specific uses.

Can EPDM be injection molded?

Yes, EPDM can also be processed via injection molding, but transfer molding is preferred for inserts.

Does EPDM float in water?

No, density is typically 0.9–1.3 g/cm³, so it usually sinks.

Is EPDM food-safe?

With FDA-approved formulations, EPDM can be food-grade.

Can EPDM be bonded to metals?

Yes, with appropriate primers and adhesives in transfer molding.

Why is ENB preferred over DCPD in EPDM?

ENB provides faster cure, better heat resistance.

Can EPDM be vulcanized without sulfur?

Yes, peroxide curing is common.

What gases can EPDM resist?

Steam, CO₂, nitrogen, but not hydrocarbons.

Is EPDM biodegradable?

No, but recycling is possible.

What colors are available in EPDM?

Black is common, but other colors possible with pigments.

Why does EPDM have long outdoor life?

Its saturated backbone resists ozone attack.

Can EPDM be used in brake fluid systems?

Yes, it is compatible with glycol-based fluids.

What is EPDM’s compression set?

Typically 10–40% depending on cure system.

Does EPDM resist acids?

Yes, dilute acids; not concentrated ones.

What happens if EPDM is exposed to oil?

It swells and degrades.

Can EPDM withstand freezing temperatures?

Yes, down to –50°C without cracking.

Is EPDM flammable?

Yes, burns slowly; flame-retardant grades available.

Can EPDM be painted?

Surface treatment needed for adhesion.

How does EPDM compare with Neoprene (CR)?

EPDM is better for weather; CR is better for oil.

Why is EPDM cheaper than Silicone?

Simpler polymerization, cheaper raw materials.

Does EPDM conduct electricity?

No, it is an insulator.

Very efficiently written article. It will be helpful to everyone who employess it, as well as me. Keep doing what you are doing – looking forward to more posts.

I must say this article is extremely well written, insightful, and packed with valuable knowledge that shows the author’s deep expertise on the subject, and I truly appreciate the time and effort that has gone into creating such high-quality content because it is not only helpful but also inspiring for readers like me who are always looking for trustworthy resources online. Keep up the good work and write more. i am a follower.

I’ve been following your blog for some time now, and I’m consistently blown away by the quality of your content. Your ability to tackle complex topics with ease is truly admirable.

You’ve made this topic far more understandable — thank you!

Brilliant!! I’m so glad I clicked this!

You’re such a vibrant writer — this was amazing!

Such a beautifully expressed and insightful article.

Whoa! This blog looks exactly like my old one! It’s on a entirely different topic but it has pretty much the same page layout and design. Superb choice of colors!

You communicate ideas with so much ease and clarity.

This post shows why your blog stands out from the rest.

Every point you made here resonated with me.

Absolutely brilliant — I’ll be bookmarking this!

This was smart, helpful, and beautifully written.

Your writing always inspires me.

This is top-tier enthusiastic writing — amazing!

You have a natural gift for teaching through writing.

Your writing is powerful and uplifting — fantastic job!

I learned so much from this one article.

I genuinely look forward to your content every time.

Your writing always inspires me.

Thank you for expressing this so clearly.

This had so much spark and energy — WOW!

You always bring clarity to confusing subjects.

This was such an enlightening read — thank you for sharing your expertise!

This was both insightful and enjoyable — perfect combination.

You’ve made this topic far more understandable — thank you!

Your blog is truly becoming a go-to resource.

This was so well organized and easy to understand.

You have an incredible ability to communicate complex ideas.

This was such a meaningful and insightful post.

Your enthusiasm makes this post unforgettable!

You’ve made this topic far more understandable — thank you!

Seriously HIGH-VIBRATION content — amazing job!

I appreciate the genuine passion you bring to your work.

I admire the clarity and depth in your writing.

Your blog is becoming one of my favorite places to learn!

You’ve absolutely nailed it — incredible writing!

You’ve created something vibrant and exciting — amazing job!

This post absolutely SPARKLES with enthusiasm!

So many great insights packed into one post.

This was a fantastic read — well done!

I’ll definitely be reading more from you.

I genuinely look forward to your content every time.

This was such an energizing read — loved it!

This post is absolutely glowing with passion!

I am now not certain where you’re getting your info, however good topic. I needs to spend some time finding out much more or figuring out more. Thanks for great info I used to be on the lookout for this info for my mission.