Overview

In the world of mechanical engineering and precision manufacturing, it’s often the smallest components that make the biggest difference. One such unsung hero in the realm of fasteners and mechanical controls is the ball plunger spring. These unassuming little springs may not be as famous as gears or bearings, but they play a vital role in countless applications across various industries. In this article, we will delve into the world of ball plunger springs, exploring their design, functionality, applications, and why they have such a big impact despite their small size.

The Basics: What Are Ball Plunger Springs?

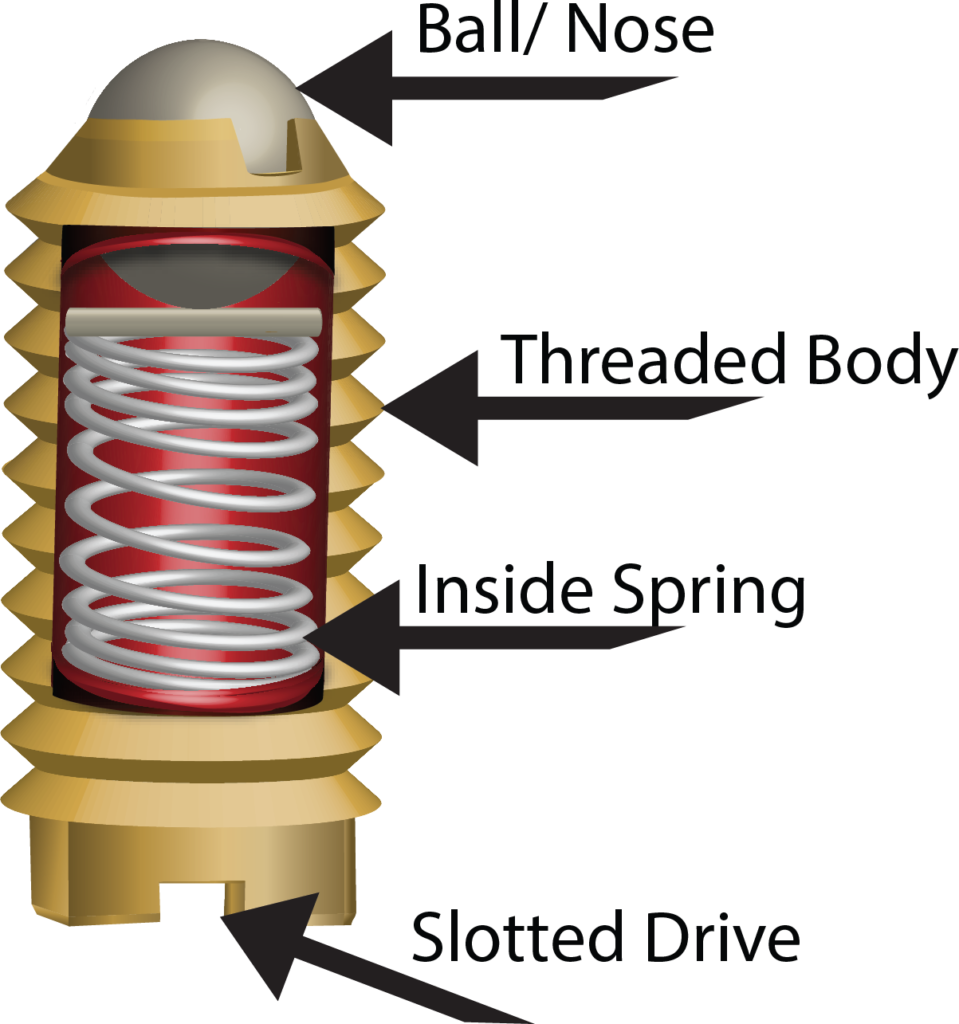

Before we dive into their significance, let’s start with the basics. Ball plunger springs, also known as spring plungers or ball detent plungers, are mechanical devices consisting of a spring-loaded ball-bearing or plunger pin encased in a threaded or unthreaded body. These components are typically made of materials like stainless steel, carbon steel, or plastic, depending on the application’s requirements.

The key elements of a ball plunger spring include –

- Body: The main cylindrical or flat component that houses the spring and ball bearing. The body can be threaded or smooth, depending on the design.

- Spring: The spring within the body provides the necessary force to keep the ball in place or to push it outward when needed.

- Ball Bearing or Plunger Pin: This is the small, rounded element that extends from the body when the spring’s force is overcome. It can be in the form of a ball bearing or a pin-like plunger.

How Do Ball Plunger Springs Work?

The operation of a ball plunger spring is elegantly simple. When the plunger is pushed or threaded into a hole or recess, the spring compresses, and the ball bearing or plunger pin retracts into the body, allowing for easy insertion or adjustment. Once the plunger reaches its desired position, the spring force pushes the ball bearing or plunger pin outward, creating resistance and securing the position.

In essence, ball plunger springs act as mechanical detents, providing a precise and repeatable stopping point or holding force. This functionality makes them incredibly versatile in various applications where precision and control are paramount.

Applications of Ball Plunger Springs

The versatility and reliability of ball plunger springs make them indispensable across a wide range of industries and applications. Here are some common areas where these small components have a big impact –

1. Manufacturing and Machinery

In the world of manufacturing, precision is everything. Ball plunger springs find extensive use in fixtures, jigs, and machinery to create quick, secure, and adjustable setups. They are often employed to hold workpieces in place during machining or assembly processes, ensuring consistent and accurate results.

2. Tool and Die Making

Tool and die makers rely on ball plunger springs to position and secure various components in their machines. These springs enable quick and precise adjustments, contributing to the production of high-quality tools and dies.

3. Automotive Industry

In the automotive industry, ball plunger springs are used in various applications, including door handles, seat adjustments, and gearshift mechanisms. They help ensure that these components stay in their designated positions, providing comfort and safety to drivers and passengers.

4. Aerospace and Defense

Ball plunger springs are crucial in aerospace and defense applications, where precision and reliability are paramount. They are used in mechanisms for securing critical components and in equipment used on aircraft and military vehicles.

5. Electronics and Consumer Goods

In the electronics industry, ball plunger springs are found in devices such as switches and connectors. They provide tactile feedback and help maintain electrical connections. In consumer goods, they are used in products like retractable pens and retractable measuring tapes.

6. Medical Equipment

In medical devices and equipment, ball plunger springs play a vital role in ensuring that components remain securely in place. This is especially critical in devices such as surgical instruments and diagnostic equipment, where precision and stability are essential.

Advantages of Ball Plunger Springs

The widespread use of ball plunger springs can be attributed to several advantages they offer –

1. Precision and Repeatability

Ball plunger springs provide precise and repeatable positioning, making them ideal for applications that require consistent accuracy.

2. Easy Installation and Adjustment

They are relatively easy to install and adjust, thanks to their simple design. This ease of use contributes to efficiency in various processes.

3. Longevity and Durability

Ball plunger springs are known for their durability and resistance to wear and tear, ensuring a long service life.

4. Minimal Space Requirements

Their compact size allows for integration into tight spaces where other fastening methods might not be feasible.

5. Cost-Effective Solutions

Ball plunger springs offer cost-effective solutions for achieving controlled motion and positioning, making them a preferred choice in many industries.

Selecting the Right Ball Plunger Spring

Choosing the appropriate ball plunger spring for a specific application requires careful consideration of several factors:

1. Load Capacity

Determine the amount of force the spring needs to exert to hold or secure the component in place.

2. Material Selection

Select the right material for the body, spring, and ball bearing or plunger pin based on factors such as environmental conditions and the application’s requirements.

3. Size and Form Factor

Consider the available space and design constraints when selecting the size and form factor of the ball plunger spring.

4. Installation Method

Choose between threaded and unthreaded bodies, depending on the ease of installation and adjustment required.

5. Environmental Factors

Consider factors such as temperature, humidity, and exposure to corrosive substances when selecting a ball plunger spring for a specific environment.

Troubleshooting Common Issues with Ball Plunger Springs

Ball plunger springs, despite their small size, play a significant role in various mechanical systems across industries. They provide precise and repeatable positioning and holding forces, contributing to the reliability and efficiency of these systems. However, like any mechanical component, ball plunger springs can encounter issues that affect their performance. In this article, we will explore some common problems associated with ball plunger springs and provide troubleshooting tips to address these issues effectively.

Issue 1: Insufficient Holding Force

One of the primary purposes of ball plunger springs is to exert a holding force, keeping components or workpieces in place. When you encounter insufficient holding force, it can lead to alignment problems and compromised performance in your mechanical system.

Possible Causes:

- Wear and Tear: Over time, the spring or ball bearing can experience wear and lose their original tension, reducing the holding force.

- Incorrect Spring Selection: Choosing a spring with an inadequate load capacity for the application can result in insufficient holding force.

Troubleshooting Tips:

- Inspect and Replace: Regularly inspect the ball plunger spring for signs of wear and replace it if necessary.

- Check Load Capacity: Ensure that you have selected a ball plunger spring with the appropriate load capacity for the specific application.

Issue 2: Difficulty in Adjustment or Movement

Ball plunger springs should allow for easy adjustment or movement when necessary. If you encounter resistance or difficulty in adjusting or moving the plunger, it can hinder the flexibility of your mechanical system.

Possible Causes:

- Contamination: Dust, debris, or other foreign particles can accumulate around the plunger, causing it to jam.

- Corrosion: Exposure to corrosive environments can lead to rust or corrosion, affecting the smooth movement of the plunger.

Troubleshooting Tips:

- Clean the Plunger: Carefully clean the plunger and its surrounding area to remove any contaminants that may be causing the resistance.

- Apply Lubrication: Use a suitable lubricant to ensure smooth movement. Be sure to choose a lubricant compatible with the materials of the ball plunger spring.

Issue 3: Premature Wear and Failure

Ball plunger springs are known for their durability, but they can still experience premature wear or failure if not properly maintained.

Possible Causes:

- Excessive Load: Subjecting the ball plunger spring to loads beyond its specified capacity can lead to premature wear and failure.

- Improper Installation: Incorrect installation or over-tightening can place unnecessary stress on the spring, reducing its lifespan.

Troubleshooting Tips:

- Review Load Conditions: Ensure that the ball plunger spring is not subjected to loads exceeding its specified capacity. Consider using a spring with a higher load capacity if necessary.

- Check Installation: Review the installation process to ensure it is carried out correctly and without over-tightening.

Issue 4: Inconsistent Positioning

In applications that require precise positioning, inconsistent movement or positioning can be a significant problem.

Possible Causes:

- Inadequate Lubrication: Lack of lubrication can result in uneven movement, leading to inconsistent positioning.

- Debris Accumulation: The presence of foreign particles can disrupt the smooth operation of the ball plunger spring.

Troubleshooting Tips:

- Lubricate as Needed: Apply lubrication as recommended by the manufacturer to maintain consistent movement and positioning.

- Regular Cleaning: Perform regular cleaning and maintenance to prevent the accumulation of debris or contaminants.

Issue 5: Noisy Operation

Unusual noises during the operation of ball plunger springs can be indicative of underlying issues.

Possible Causes:

- Lack of Lubrication: Insufficient lubrication can result in friction and noise during movement.

- Wear or Damage: Wear or damage to the ball plunger spring components can lead to noise.

Troubleshooting Tips:

- Apply Lubrication: Ensure that the ball plunger spring is adequately lubricated to reduce friction and noise.

- Inspect for Damage: Carefully inspect the components of the ball plunger spring for any signs of wear or damage and replace as needed.

Conclusion: The Unseen Heroes of Precision Engineering

In the world of precision engineering and manufacturing, it’s easy to overlook the small components that quietly perform their roles with precision and reliability. Ball plunger springs are perfect examples of these unseen heroes. Despite their modest size and unassuming appearance, they play a crucial role in ensuring the smooth operation of countless mechanical systems and processes.

As technology advances and industries demand ever-higher levels of precision and control, the importance of ball plunger springs is only set to grow. These small components will continue to have a big impact, helping engineers and manufacturers achieve the precision they need to create safe, reliable, and efficient products.

Next time you use a retractable pen, adjust your car seat, or witness the flawless operation of a manufacturing machine, take a moment to appreciate the role of ball plunger springs in making it all possible. These small components may be hidden from view, but their impact on our lives and industries is truly remarkable.

FAQ’s

What is a Ball Plunger Screw used for?

A Ball Plunger Screw is used for precise positioning and securing of components in machinery, fixtures, or assemblies. It features a retractable plunger with a ball bearing, providing adjustable and repeatable stopping points, essential in various industrial applications.

What is the difference between Spring Plunger and a Ball Plunger?

Basic differences between Spring Plunger and a Ball Plunger are –

1. Design:

Spring Plunger: A spring plunger consists of a spring-loaded plunger pin within a threaded or unthreaded body.

Ball Plunger: A ball plunger features a spring-loaded ball bearing or plunger pin encased in a threaded or unthreaded body, with a small ball-shaped tip.

Function:

Spring Plunger: It exerts force through the plunger pin and is often used for positioning and indexing.

Ball Plunger: It uses a ball bearing or plunger pin for precise positioning and providing resistance, creating a detent effect.

Applications:

Spring Plunger: Commonly used in indexing, locating, and positioning applications.

Ball Plunger: Widely used for applications requiring controlled motion, such as locking, latching, and securing components.

Operation:

Spring Plunger: The plunger pin extends or retracts when pressure is applied or released.

Ball Plunger: The ball bearing or plunger pin extends when pressure is applied and retracts when released, creating a tactile feedback mechanism.

Typical Uses:

Spring Plunger: Found in tooling, fixtures, and indexing mechanisms.

Ball Plunger: Used in applications where precise, repeatable positioning and resistance are essential, such as in machinery and equipment.

What are the three types of Plunger?

There are three common types of plungers –

Spring Plunger: Contains a spring-loaded plunger pin within a body and is used for positioning and indexing in various applications.

Ball Plunger: Features a spring-loaded ball bearing or plunger pin within a body and provides precise positioning and resistance, often used for locking and latching mechanisms.

Pin Plunger: Consists of a simple, spring-loaded plunger pin within a body, used for straightforward positioning tasks and detent applications.

What are the benefits of Plunger?

Plungers offer several benefits, including –

Precision: They provide accurate and repeatable positioning, ensuring components align precisely.

Adjustability: Plungers are often adjustable, allowing for fine-tuning and customization in various applications.

Versatility: They have a wide range of uses in indexing, locking, latching, and securing components.

Reliability: Plungers are durable and reliable, contributing to the stability of mechanical systems.

Cost-Efficiency: They offer cost-effective solutions for achieving controlled motion and positioning in industrial processes.

What is a Force Ball Plunger?

A Force Ball Plunger, also known as a force ball detent, is a specific type of ball plunger that is designed to exert a controlled and measurable force. It consists of a spring-loaded ball bearing or plunger pin within a threaded or unthreaded body, but what sets it apart is its ability to provide a consistent and calibrated force when the ball is pushed or pressed.

These plungers are often used in applications where maintaining a specific level of force is critical, such as in quality control equipment, testing fixtures, or mechanical systems where precise force feedback is necessary for reliable operation.

How Ball Plunger locking mechanism works?

A Ball Plunger locking mechanism works by using a spring-loaded ball bearing or plunger pin within a body. When pressure is applied to the plunger, the ball bearing or pin extends, engaging with a corresponding hole, notch, or groove in another component.

This engagement creates a secure and often reversible locking action, preventing movement or disengagement until the pressure is released, allowing the ball to retract. This mechanism is widely used in applications where quick and reliable locking and unlocking are necessary, such as in doors, latches, and machinery.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.