In today’s highly competitive manufacturing environment, companies face intense pressure to deliver high-quality, reliable, and cost-effective products at faster speeds. To achieve this, organizations rely on structured quality planning methodologies, one of the most widely used being APQP (Advanced Product Quality Planning).

APQP is a structured, step-by-step approach that ensures product and process quality planning begins at the earliest stages of development and continues through production and customer feedback. Initially developed in the automotive industry by the AIAG (Automotive Industry Action Group), APQP has since become a global standard across industries where quality, safety, and reliability are critical.

Whether you are an engineer, project manager, or quality leader, mastering the APQP process is essential for delivering products that meet customer needs while controlling costs and risks.

The Evolution and History

- 1980s – The “Big Three” automotive companies in the U.S. (Ford, GM, Chrysler) realized the need for a standardized quality framework to manage supplier development.

- AIAG (Automotive Industry Action Group) developed the APQP manual to unify expectations across OEMs and suppliers.

- Over the years, APQP became a core requirement for suppliers working with global automakers.

- Today, APQP is not only used in automotive but also in aerospace, defense, medical devices, consumer electronics, and heavy machinery industries.

Why APQP Matters

Imagine launching a new car model without thoroughly testing parts, processes, and customer expectations. The result would be frequent recalls, warranty claims, and loss of trust.

This is why APQP is critical:

- It provides a roadmap for planning quality into products.

- Prevents failures by identifying risks early.

- Ensures cross-functional collaboration between design, manufacturing, quality, and suppliers.

- Meets compliance requirements (IATF 16949, ISO 9001, AS9100).

- Saves time and money by eliminating late-stage surprises.

Key Objectives of APQP

- Define customer requirements clearly and accurately.

- Establish design, quality, and process goals early.

- Proactively identify and mitigate risks (using DFMEA & PFMEA).

- Validate product and process capability before mass production.

- Promote continuous improvement throughout the product life cycle.

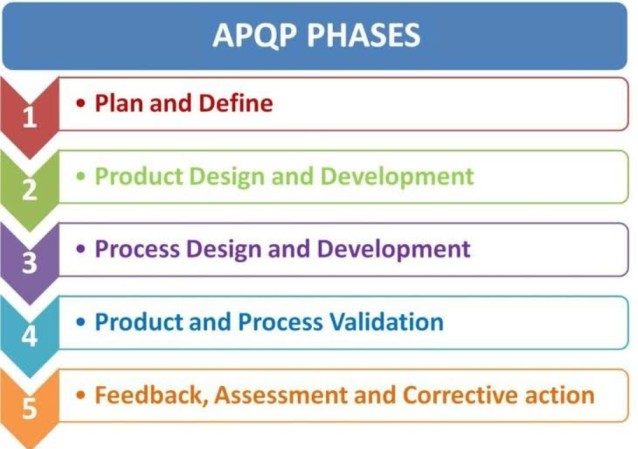

The 5 Phases of APQP Process

Phase 1: Plan and Define Program

This is the foundation phase where customer needs are translated into project goals.

Main tasks include:

- Collecting Voice of Customer (VOC) through surveys, past complaints, or benchmark studies.

- Translating VOC into technical requirements.

- Reviewing regulations, safety requirements, and industry standards.

- Preparing a business case and feasibility analysis.

- Developing program timing plans and resource allocation.

- Conducting preliminary risk assessment.

Deliverables (Outputs):

- Design goals.

- Preliminary BOM.

- Reliability and quality objectives.

- Preliminary process flow chart.

- Benchmarking reports.

📌 Example: In automotive, when planning a new fuel injection system, customer needs like fuel efficiency, emissions, and reliability are translated into measurable technical requirements (e.g., max 5% deviation in fuel flow, compliance with Euro 6 norms).

Phase 2: Product Design and Development

Here, the product design takes shape with a focus on manufacturability and customer satisfaction.

Main tasks include:

- Creating 2D/3D CAD models and simulations.

- Performing Design Failure Mode and Effects Analysis (DFMEA) to identify design risks.

- Evaluating materials and alternative solutions.

- Building prototypes for validation.

- Conducting Design Verification Plan and Report (DVP&R) testing.

- Reviewing compliance with regulatory and safety standards.

Deliverables (Outputs):

- Engineering drawings.

- DFMEA documentation.

- Prototype builds.

- Special product characteristics list.

- Updated design validation reports.

📌 Example: While developing an airbag system, DFMEA identifies risks like delayed deployment. Solutions such as sensor redundancy and faster inflator mechanisms are implemented at this stage.

Phase 3: Process Design and Development

Focus shifts to manufacturing process design capable of consistent quality production.

Main tasks include:

- Developing Process Flow Charts showing every step.

- Performing Process FMEA (PFMEA) for risk assessment.

- Establishing work instructions, inspection methods, and packaging standards.

- Preparing gauging and tooling requirements.

- Conducting process capability studies (Cp, Cpk).

Deliverables (Outputs):

- PFMEA documentation.

- Control Plan (prototype, pre-launch, production).

- Process flow diagram.

- Gage R&R and equipment qualification.

- Logistics and packaging plan.

📌 Example: In a plastic injection molding process, PFMEA may highlight risks like mold wear, flash formation, or incorrect temperature. Countermeasures include preventive maintenance schedules and real-time monitoring sensors.

Phase 4: Product and Process Validation

This phase confirms that the product and process meet customer requirements under production conditions.

Main tasks include:

- Conducting Production Trial Runs.

- Performing Measurement System Analysis (MSA) to confirm accuracy of inspection tools.

- Conducting Statistical Process Control (SPC) studies to measure variation.

- Submitting Production Part Approval Process (PPAP) documents to customers.

- Packaging and logistics validation.

Deliverables (Outputs):

- PPAP submission and approval.

- MSA study results.

- Process validation results.

- Updated control plans.

📌 Example: For an engine cylinder head, a production run is performed, measurements are taken with CMM (Coordinate Measuring Machine), and results prove the process is stable before mass production begins.

Phase 5: Feedback, Assessment, and Continuous Improvement

After production launch, APQP doesn’t stop. Continuous monitoring and improvement ensure long-term product success.

Main tasks include:

- Gathering customer feedback (warranty claims, complaints, satisfaction surveys).

- Tracking production performance (scrap rates, rework, downtime).

- Conducting Layered Process Audits (LPA).

- Implementing corrective actions using 8D or root cause analysis.

- Updating control plans, FMEAs, and lessons learned.

Deliverables (Outputs):

- Continuous improvement reports.

- Updated documentation.

- Customer scorecards.

- Warranty reduction reports.

📌 Example: A supplier producing brake pads monitors field data and finds abnormal wear in certain climates. The PFMEA and process parameters are updated to improve durability.

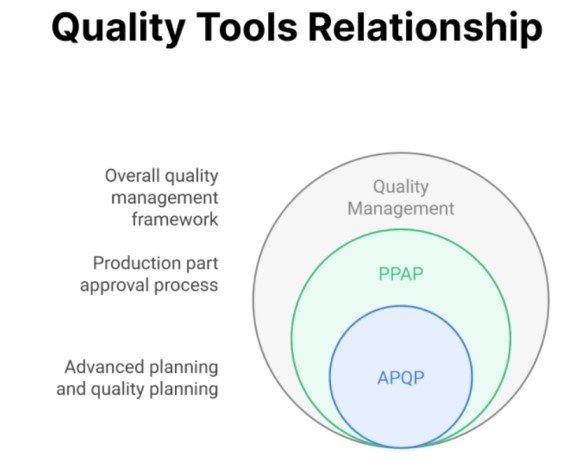

Core Tools Supporting APQP (Expanded)

- FMEA (Failure Mode and Effects Analysis) – DFMEA & PFMEA help identify and mitigate risks.

- PPAP (Production Part Approval Process) – Ensures production readiness before shipment.

- MSA (Measurement Systems Analysis) – Confirms accuracy and repeatability of measuring systems.

- SPC (Statistical Process Control) – Monitors process variation to ensure stability.

- Control Plan – Document defining inspection methods, frequency, and response plans.

Real-World APQP Example (Automotive Plastic Part)

Let’s say a supplier is tasked with developing a plastic dashboard component for a new car model.

- Phase 1: Gather VOC – lightweight, low VOC emissions, stylish finish.

- Phase 2: Design dashboard CAD, perform DFMEA, build prototypes.

- Phase 3: Develop injection molding process, PFMEA highlights risks like color shade variation.

- Phase 4: Trial run, MSA confirms color measurement repeatability, PPAP submitted.

- Phase 5: Post-launch feedback shows scratch resistance issues → supplier updates material specs.

Benefits of APQP

- Cost savings by preventing late changes.

- Improved reliability and customer trust.

- Better supplier collaboration.

- Faster product launch.

- Compliance with standards (IATF 16949, ISO 9001, AS9100).

Common Challenges and Solutions

- Challenge: Resistance to documentation → Solution: Use digital APQP tools.

- Challenge: Lack of cross-functional teamwork → Solution: Early supplier involvement.

- Challenge: Time-consuming PPAP → Solution: Parallel validation activities.

FAQs

Q1. What is APQP in simple words?

APQP (Advanced Product Quality Planning) is a structured process used to ensure that a product meets customer requirements. It guides companies through planning, designing, validating, and continuously improving products and processes before mass production. Simply put: it’s a roadmap for building quality into a product from the very beginning

Q2. Who developed APQP?

APQP was developed in the late 1980s by the AIAG (Automotive Industry Action Group) in collaboration with the “Big Three” U.S. automakers (Ford, General Motors, and Chrysler). The goal was to create a standardized approach for suppliers to ensure quality and consistency.

Q3. What industries use APQP besides automotive?

Although APQP started in automotive, today it is widely used in:

- Aerospace and defense

- Medical devices

- Consumer electronics

- Heavy machinery and industrial equipment

- Renewable energy and power systems

Any industry requiring high reliability and strict compliance can benefit from APQP.

Q4. Is APQP mandatory for IATF 16949?

Yes. IATF 16949, the global quality standard for automotive suppliers, requires APQP as a core element. Companies that want to supply to OEMs (Original Equipment Manufacturers) must follow APQP or demonstrate an equivalent planning process.

Q5. What are APQP deliverables?

The key deliverables of APQP include:

- Design FMEA (DFMEA)

- Process FMEA (PFMEA)

- Process Flow Diagrams

- Control Plans

- Measurement System Analysis (MSA) results

- Capability studies (Cp, Cpk)

- PPAP (Production Part Approval Process) package

These documents prove that the product and process can consistently meet customer expectations.

Q6. How is APQP different from Six Sigma?

- APQP is a framework for product and process quality planning.

- Six Sigma is a methodology for reducing variation and defects.

- While both focus on quality improvement, APQP is project-based (used during product launch), whereas Six Sigma is ongoing (used during production and improvement cycles).

Q7. Can small businesses implement APQP?

Yes. Small and medium-sized enterprises (SMEs) can benefit from APQP by scaling it according to project size. Even a simplified APQP helps them reduce defects, improve customer trust, and meet supplier requirements without overwhelming documentation.

Q8. What is the link between APQP and Lean Manufacturing?

APQP and Lean Manufacturing complement each other. APQP focuses on planning and preventing defects, while Lean eliminates waste and inefficiencies. When combined, they lead to faster product launches, reduced costs, and higher quality.

Q9. What documents are included in PPAP?

A typical PPAP submission may include up to 18 elements, such as:

- Design records

- Engineering change documents

- DFMEA & PFMEA

- Process flow diagram

- Control plan

- Measurement System Analysis (MSA)

- Initial process studies (Cp, Cpk)

- Appearance approval reports

- Sample parts

- Part submission warrant (PSW)

Q10. What happens if a supplier skips APQP steps?

Skipping APQP steps often results in:

- Product defects and recalls

- Higher warranty claims

- Customer dissatisfaction

- Delays in project launch

- Risk of losing supplier approval from OEMs

That’s why most OEMs strictly enforce APQP compliance.

Q11. Is APQP applicable in service industries?

While APQP was designed for manufacturing, its principles (planning, risk analysis, validation, continuous improvement) can be applied to service industries such as healthcare, IT, or logistics. For example, PFMEA-like methods can be used to identify service process failures.

Q12. How does APQP reduce recalls?

By performing DFMEA and PFMEA early, APQP identifies potential failures before the product reaches customers. Testing, validation, and process capability studies further ensure defects are minimized, significantly reducing the chance of costly product recalls.

Q13. What is a control plan in APQP?

A Control Plan is a document that defines:

- What needs to be measured or inspected.

- How often checks should be performed.

- Which methods or equipment should be used.

- What actions should be taken if a problem occurs.

It ensures consistent monitoring and control of product and process quality.

Q14. How does SPC help in APQP?

Statistical Process Control (SPC) uses charts and statistical tools to monitor process variation. In APQP, SPC is applied during validation and production to ensure that processes remain stable and capable of consistently meeting specifications.

Q15. What is the difference between APQP and NPI (New Product Introduction)?

APQP is a formalized, standardized methodology, mainly used in automotive and aerospace.

NPI is a broader concept that refers to all activities required to launch a new product in any industry.

APQP can be considered a specialized form of NPI with strict quality standards.

Q16. Is APQP software available?

Yes. Many digital tools and platforms support APQP, DFMEA, PFMEA, and PPAP management. Examples include Siemens Teamcenter, APIS IQ-Software, Omnex, and other quality management systems (QMS). These tools streamline documentation and collaboration.

Q17. What role do customers play in APQP?

Customers are involved throughout APQP. They provide requirements, design approval, PPAP acceptance, and feedback during production. Their involvement ensures alignment and reduces risk of miscommunication.

Q18. What is layered process audit in APQP?

A Layered Process Audit (LPA) is a structured audit conducted at different organizational levels (operator, supervisor, manager). In APQP, LPAs verify that the control plan and process standards are consistently followed, supporting continuous improvement.

Q19. How are lessons learned used in APQP?

Lessons learned from past projects (e.g., failures, successful practices) are documented in Phase 5 and applied to future projects. This ensures mistakes are not repeated and best practices are reused for faster, more reliable APQP execution.

Q20. What is the timeline of a typical APQP cycle?

The timeline depends on project complexity.

- Simple projects: 3–6 months.

- Automotive programs: 12–18 months.

- Aerospace/medical devices: May take 24 months or more.

Early planning and overlapping activities can shorten timelines.

Q21. Can APQP and Agile work together?

Yes. While APQP is structured and documentation-heavy, Agile emphasizes flexibility and rapid iteration. Combining them allows companies to adapt designs quickly (Agile) while still meeting regulatory quality requirements (APQP).

Q22. Is APQP evolving with Industry 4.0?

Yes. With Industry 4.0, APQP is becoming more digital and data-driven. Real-time SPC monitoring, IoT-enabled machines, AI-powered FMEA analysis, and cloud-based PPAP tools are transforming APQP into a faster, more predictive quality planning process.

Conclusion

The APQP process provides a comprehensive framework that connects design, manufacturing, and customer requirements into a unified roadmap. By following its five structured phases, organizations minimize risks, reduce costs, and deliver high-quality, reliable products that satisfy customers.

In industries where a single defect can lead to massive recalls or safety risks, APQP is not just a requirement—it’s a competitive advantage.

- Thermoplastic Elastomers (TPE) Material Explained: Types, Properties, Applications & Market

- Comprehensive Guide on Thermoplastic Olefin (TPO) Material – Point-to-Point Explanation

- All-in-One Hot Runner Mold Repair and Troubleshooting Manual

- Comprehensive guide on EPDM in Transfer Molding: Definition, Composition, Manufacturing, Shelf Life, Properties, Pros & Cons, Applications, FAQs.

- Mold Preventive Maintenance Checksheet

It’s going to be finish of mine day, except before ending I am reading

this fantastic article to increase my know-how.

I have read a few just right stuff here. Definitely worth bookmarking for revisiting. I surprise how a lot attempt you set to create one of these excellent informative web site.

Its such as you learn my mind! You seem to grasp so much about this,

such as you wrote the e book in it or something.

I believe that you simply can do with some p.c. to pressure the message home a

bit, but other than that, this is wonderful blog. A fantastic read.

I will definitely be back.

Hi, after reading this awesome article i am as well glad to share my know-how here with friends.

What’s up, every time i used to check web site posts here early

in the morning, for the reason that i love to find out more and more.

👍

I like the valuable information you provide in your articles. I will bookmark your weblog and check again here frequently. I am somewhat certain I’ll be informed lots of new stuff right here! Best of luck for the next!

Very interesting topic, thankyou for putting up.

I am often to blogging and i really admire your content. The article has really peaks my interest. I’m going to bookmark your site and preserve checking for new information.

Nicely delivered

Magnificent website. Plenty of useful info here. I am sending it to a few friends ans also sharing in delicious. And of course, thanks for your effort!

This article will assist the internet people for setting

up new website or even a blog from start to end.

I would like to thnkx for the efforts you have put in writing this blog. I am hoping the same high-grade blog post from you in the upcoming as well. In fact your creative writing abilities has inspired me to get my own blog now. Really the blogging is spreading its wings quickly. Your write up is a good example of it.