Thermoplastic Elastomers (TPE) Material Explained: Types, Properties, Applications & Market

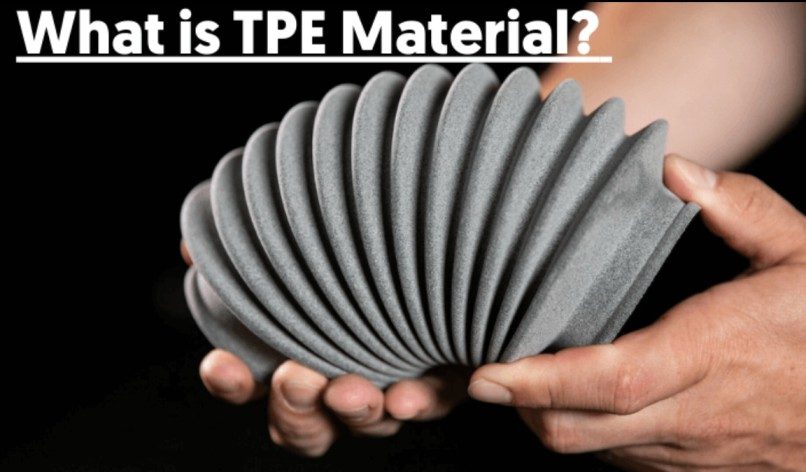

Introduction to Thermoplastic Elastomers (TPE) Thermoplastic Elastomers (TPEs) are a unique class of polymer materials that combine the elasticity of rubber with the easy processability of plastics. This dual nature makes TPE one of the most versatile and widely used engineering materials in modern industries. Unlike traditional rubber, which requires curing or vulcanization, TPE can … Read more