Introduction to Thermoplastic Elastomers (TPE)

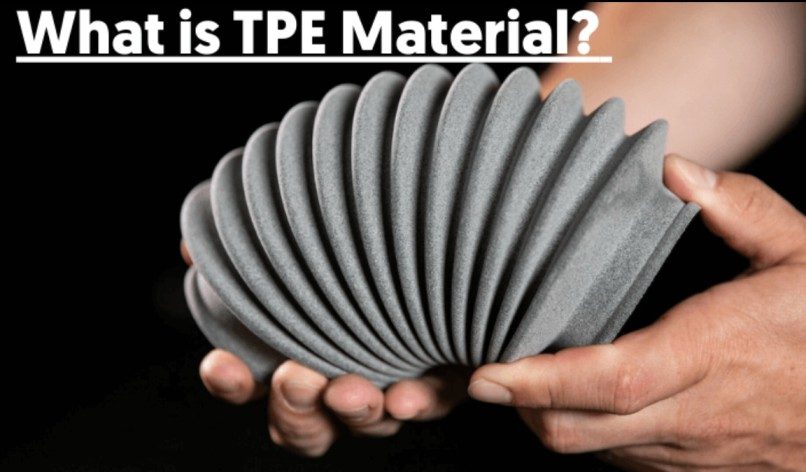

Thermoplastic Elastomers (TPEs) are a unique class of polymer materials that combine the elasticity of rubber with the easy processability of plastics. This dual nature makes TPE one of the most versatile and widely used engineering materials in modern industries. Unlike traditional rubber, which requires curing or vulcanization, TPE can be processed using standard thermoplastic methods like injection molding, extrusion, and blow molding, making it cost-effective and highly adaptable.

TPE has gained importance due to its ability to deliver flexibility, durability, and soft-touch comfort while still being recyclable. For example, in the automotive industry, TPE is used in bumpers, weather seals, and interior trims. In consumer goods, it is found in grips, footwear, and toys. The medical field also benefits from TPE in applications like tubing, seals, and flexible housings, where safety and comfort are critical.

Globally, the demand for TPE has grown significantly over the last three decades. Its use has expanded beyond automotive into electronics, construction, and healthcare sectors, driven by trends in lightweighting, environmental regulations, and the need for sustainable alternatives to PVC and rubber. TPE grades are available in various hardness levels, ranging from very soft gels to rigid elastomers, allowing designers and engineers to choose materials tailored to specific needs.

In simple terms, TPE bridges the gap between plastics and rubbers. It provides the flexibility of elastomers and the reusability of plastics, enabling manufacturers to design products that are durable, safe, and eco-friendly. As industries continue to innovate and push for sustainability, TPE will play an even more crucial role in the future of materials engineering.

Definition and Basics of Thermoplastic Elastomers (TPE)

Thermoplastic Elastomers (TPEs) are a family of polymers that combine the characteristics of both thermoplastics and elastomers. To understand TPE in depth, let us break down its definition, core principles, and why it is considered a revolutionary material.

Definition of TPE

TPEs are materials that behave like rubber (flexible, stretchable, and resilient) at room temperature but can be melted and reprocessed like plastics when heated. This unique combination is achieved because TPEs consist of both hard crystalline domains and soft amorphous domains within their molecular structure.

- The hard segments give the material strength, durability, and processability.

- The soft segments provide elasticity, flexibility, and a rubber-like feel.

Thus, TPE can be shaped multiple times without undergoing chemical changes, unlike vulcanized rubber, which cannot be remelted or reshaped once cured.

Key Characteristics

- Elastic Behavior: TPE stretches like rubber and returns to its original shape.

- Thermoplastic Processing: It can be molded, extruded, or recycled just like regular plastics.

- Soft-touch Feel: Provides comfort in products like grips, handles, and medical devices.

- Lightweight: Lower density compared to traditional rubber or PVC.

- Recyclability: Scrap and waste material can be reused, reducing production costs and environmental impact.

Difference Between TPE, Rubber, and Plastics

- Rubber: Requires vulcanization, is not recyclable, and has limited processing methods.

- Plastics: Easy to process, but rigid and brittle in many applications.

- TPE: Offers the best of both worlds—rubber-like elasticity with plastic-like processability.

- For example, TPE can replace PVC in flexible tubing applications while being safer and more eco-friendly. It can also substitute natural rubber in seals and gaskets, offering longer service life and recyclability.

Types of Thermoplastic Elastomers (TPE) at a Glance

TPE is not a single material but a broad category of polymers, including:

- Styrenic Block Copolymers (SBCs/TPS) – used in footwear, adhesives, and toys.

- Thermoplastic Polyolefins (TPOs) – used in automotive bumpers and roofing membranes.

- Thermoplastic Vulcanizates (TPVs) – used in seals, hoses, and gaskets.

- Thermoplastic Polyurethanes (TPUs) – used in cables, films, and sporting goods.

- Thermoplastic Copolyesters (COPEs) – used in mechanical parts and medical tubing.

- Thermoplastic Polyamides (PEBAX) – used in high-performance footwear and medical devices.

Each type has a different balance of elasticity, chemical resistance, and processing ease.

Why TPE is Important Today

- Sustainability: TPEs reduce waste and are safer than many alternatives like PVC.

- Versatility: One family of materials serves multiple industries—automotive, medical, consumer goods, and electronics.

- Cost Efficiency: Recyclability and simpler processing make it economical.

- Innovation Enabler: Supports modern trends such as light weighting, flexible electronics, and eco-friendly medical products.

Simple Analogy

Think of TPE as “playdough with the strength of a rubber band.” You can reshape it repeatedly like playdough when heated, but when it cools down, it retains the flexibility and durability of a rubber band.

History and Evolution of Thermoplastic Elastomers (TPE)

The journey of Thermoplastic Elastomers (TPEs) reflects the constant evolution of material science—driven by the need for flexible, durable, and easily processable materials. TPEs did not appear overnight; they are the result of decades of innovation, chemical research, and industrial demand. This chapter explores how TPE emerged, its historical timeline, and its industrial adoption.

The Need for Thermoplastic Elastomers (TPE)

Before TPE, industries mainly relied on natural rubber and vulcanized rubber for elasticity and thermoplastics for easy shaping. However, both had limitations:

- Rubber: Excellent elasticity but required complex curing (vulcanization), was not recyclable, and had limited chemical resistance.

- Plastics: Easily molded and recyclable, but rigid and brittle, lacking flexibility.

The demand for a material that could combine rubber-like flexibility with plastic-like processability led researchers to explore new polymers in the mid-20th century.

Early Research (1930s–1950s)

- In the 1930s, synthetic rubbers like neoprene and styrene-butadiene rubber (SBR) were developed, mainly for tire applications.

- In the 1940s, after World War II, the automotive and consumer industries sought materials that could replace costly natural rubber imports.

- By the 1950s, scientists began experimenting with block copolymers, which would later become the foundation of many TPEs.

- This period laid the groundwork for combining elastomeric properties with thermoplastic behavior.

The Birth of Thermoplastic Elastomers (TPE) (1960s–1970s)

- 1960s: The first Styrenic Block Copolymers (SBCs) were commercialized by Shell Chemicals under the brand name Kraton. These became the first widely recognized TPEs. They offered soft-touch, flexibility, and easy processing.

- 1970s: The development of Thermoplastic Polyurethanes (TPUs) provided a new class of TPE with higher abrasion resistance and toughness, ideal for footwear and sporting goods.

- This era marks the official recognition of TPE as a new family of polymers.

Expansion and Diversification (1980s–1990s)

- 1980s: Introduction of Thermoplastic Vulcanizates (TPVs) like Santoprene (developed by Monsanto). These combined dynamic vulcanization with thermoplastic processing, giving improved durability and chemical resistance.

- 1990s: Growing demand from the automotive industry for lightweight, recyclable, and durable materials boosted TPE adoption. Thermoplastic Polyolefins (TPOs) gained popularity in bumper fascias and dashboard skins.

- By this time, TPE was no longer a niche innovation but a mainstream material.

21st Century: Sustainability and High Performance

- 2000s: Environmental awareness and stricter regulations on PVC accelerated the shift towards TPEs, especially in medical and consumer goods.

- 2010s: High-performance grades of TPE emerged, including bio-based TPEs, flame-retardant versions, and medical-grade variants.

- 2020s: TPEs continue to evolve with nanocomposites, smart materials, and recyclable formulations, aligning with circular economy goals.

Industrial Adoption Timeline

- Automotive: Adopted TPEs early for seals, gaskets, and interiors.

- Consumer Goods: Used in grips, footwear, and toys due to comfort and safety.

- Medical: Expanded use in the 1990s and 2000s, replacing PVC in tubing and housings.

- Electronics: Recently, TPEs are widely used in cables, connectors, and flexible devices.

Milestones Summary

- 1930s–40s: Synthetic rubber innovations.

- 1950s: Block copolymer research.

- 1960s: Commercial launch of SBCs (Kraton).

- 1970s: Development of TPUs.

- 1980s: TPVs like Santoprene.

- 1990s: Widespread adoption in automotive and industrial products.

- 2000s–2020s: Sustainability, recyclability, and high-performance TPEs.

Why This Evolution Matters

The history of TPE is not just about chemistry—it reflects industrial innovation. Each milestone responded to a specific need: replacing natural rubber, reducing costs, enabling recyclability, or meeting environmental standards. Today, TPE is at the forefront of sustainable material solutions.

Chemical Structure and Composition of Thermoplastic Elastomers (TPE)

Understanding the chemical structure and composition of TPE is crucial to appreciating why it exhibits such unique properties—combining elasticity like rubber with processability like plastics. TPEs are not a single polymer but a family of materials with diverse molecular architectures, each designed to balance flexibility, strength, and recyclability.

Basic Concept: Dual-Phase Structure

At the molecular level, TPEs consist of two main domains:

- Hard segments (crystalline or glassy domains):

- Provide rigidity, mechanical strength, and processability.

- Ensure that the material holds its shape during use.

- Soft segments (amorphous elastomeric domains):

- Provide flexibility, stretchability, and rubber-like feel.

- Allow TPE to return to its original shape after deformation.

These segments are physically bonded rather than chemically crosslinked (like vulcanized rubber). This physical bonding allows TPE to be reheated and reshaped multiple times.

Block Copolymer Structure

Many TPEs are based on block copolymer chemistry, where distinct polymer blocks are arranged in a linear or branched fashion.

- Example: Styrene-Ethylene-Butylene-Styrene (SEBS):

- Styrene forms hard domains.

- Ethylene-Butylene forms soft, elastic domains.

This architecture creates a morphology of microdomains, giving TPE its combination of toughness and flexibility.

Composition of Thermoplastic Elastomers (TPE) Families

Different TPE families have variations in chemical composition, which tailor their performance:

- Styrenic Block Copolymers (SBCs/TPS):

- Composition: Styrene + rubbery mid-block (butadiene, isoprene, or ethylene-butylene).

- Features: Soft-touch, good flexibility, lower cost.

- Thermoplastic Polyolefins (TPOs):

- Composition: Polypropylene matrix + ethylene-propylene rubber phase.

- Features: Good toughness, used in automotive bumpers and roofing.

- Thermoplastic Vulcanizates (TPVs):

- Composition: Polypropylene + dynamically vulcanized EPDM rubber.

- Features: Excellent durability, chemical resistance, seals, and gaskets.

- Thermoplastic Polyurethanes (TPUs):

- Composition: Hard urethane segments + soft polyether/polyester segments.

- Features: High abrasion resistance, elasticity, and transparency.

- Thermoplastic Copolyesters (COPEs):

- Composition: Polyester hard blocks + flexible ether soft blocks.

- Features: Excellent fatigue resistance and thermal stability.

- Thermoplastic Polyamides (PEBA):

- Composition: Nylon hard blocks + polyether soft blocks.

- Features: Lightweight, high flexibility, used in sports shoes and medical devices.

Morphology of Thermoplastic Elastomers (TPE)

The microstructure of TPEs often consists of phase-separated domains, visible under electron microscopes:

- Hard domains appear as small dispersed spheres or lamellae.

- Soft domains create a continuous flexible matrix.

This morphology is critical to balancing strength + elasticity.

Additives in Thermoplastic Elastomers (TPE) Formulations

TPE properties can be fine-tuned with additives:

- Plasticizers: Increase softness and flexibility.

- Fillers (talc, silica, carbon black): Improve strength or reduce costs.

- Stabilizers (UV, antioxidants): Protect against degradation.

- Colorants: Allow customization for consumer products.

Key Chemical Traits

- Physical crosslinks instead of chemical ones: Allows remelting.

- Phase separation: Enables the dual properties of plastic and rubber.

- Tailor-made compositions: Different block ratios adjust hardness, elasticity, and durability.

Why Composition Matters

The exact ratio of hard to soft segments determines whether a TPE is more:

- Rubber-like (softer, flexible, elastic) → used in seals, grips, medical tubing.

- Plastic-like (stiffer, durable, strong) → used in automotive parts, housings, and roofing.

Thus, by simply altering chemical composition, TPE can serve diverse applications from toothbrush grips to automotive bumpers.

Real-World Example

A TPE phone case:

- Soft segments → allow the case to flex and absorb impact.

- Hard segments → maintain shape, protect against deformation.

- Additives → improve color, UV resistance, and durability.

This shows how molecular design translates into practical performance.

Manufacturing Process of Thermoplastic Elastomers (TPE)

The manufacturing of Thermoplastic Elastomers (TPEs) is a blend of polymer chemistry and processing technology. Unlike traditional rubbers, which require vulcanization (irreversible curing), TPEs are produced and processed through thermoplastic techniques—making them easier, faster, and more cost-effective to manufacture. This chapter explains the entire process step by step, from raw material synthesis to final product shaping.

Overview of the Thermoplastic Elastomers (TPE) Manufacturing Cycle

The process involves two major stages:

- Polymer Synthesis – Creation of base polymer (block copolymer or blend).

- Compounding & Processing – Addition of fillers, stabilizers, colorants, followed by shaping into usable products via thermoplastic methods.

Polymer Synthesis Methods

TPEs can be synthesized through various polymerization methods, depending on the type of TPE.

Block Copolymerization

- Used for Styrenic Block Copolymers (SBCs) and COPEs.

- Involves sequential polymerization of hard and soft segments.

- Example: Styrene → polymerized first to form hard block; then butadiene/isoprene → forms soft block.

Grafting Techniques

- Used for TPOs where rubber (EPDM) is blended with polypropylene.

- Compatibilizers are added to improve adhesion between phases.

Dynamic Vulcanization

- Used for TPVs (e.g., Santoprene).

- Rubber (EPDM) is dispersed in a thermoplastic matrix (PP) and simultaneously vulcanized during mixing.

- Results in micro-scale crosslinked rubber particles within plastic, combining durability with reprocessability.

Polyaddition Reactions

- Used for TPUs where diisocyanates react with polyols to form urethane bonds.

- Allows tuning of hardness by changing polyol type.

Compounding and Blending

After base polymer synthesis, compounding is performed to achieve desired properties. Additives include:

- Fillers (talc, silica, carbon black) → strength, stiffness, or cost reduction.

- Plasticizers & oils → softness and flexibility.

- Stabilizers → protect against UV, oxidation, or heat.

- Pigments → coloration for consumer appeal.

This step tailors TPE for specific industries (e.g., medical-grade, automotive-grade).

Processing Methods

TPEs are versatile and can be shaped using standard thermoplastic techniques:

Injection Molding

- Molten TPE is injected into a mold cavity and cooled.

- Applications: Seals, grips, automotive parts, footwear soles.

- Advantage: High precision, mass production capability.

Extrusion

- Material is melted and forced through a die to form continuous shapes.

- Applications: Tubing, weatherstrips, wire coatings.

- Advantage: Consistent long profiles.

Blow Molding

- Used for hollow parts by inflating molten TPE inside a mold.

- Applications: Containers, bellows, protective covers.

3D Printing (Emerging)

- Flexible TPE filaments allow production of custom components.

- Applications: Prototypes, medical models, cushioning parts.

Manufacturing Parameters

Critical parameters must be controlled:

- Temperature: Must be high enough to melt hard segments but not degrade soft ones.

- Shear rate: Excessive shear can damage polymer chains.

- Cooling rate: Controls crystallinity and final mechanical strength.

- Mixing uniformity: Ensures even distribution of rubber, fillers, and additives.

Quality Control in Thermoplastic Elastomers (TPE) Manufacturing

Manufacturers perform rigorous testing:

- Melt Flow Index (MFI): Determines processability.

- Shore Hardness (A/D): Measures softness or stiffness.

- Tensile Strength & Elongation: Ensure durability.

- Aging Tests (UV/heat): Predicts service life.

This ensures that TPE products meet strict industrial and safety standards.

Recycling and Reprocessing

One of the key advantages of TPE is recyclability:

- Scrap material from injection molding or extrusion can be ground and reprocessed.

- Unlike thermoset rubber, TPE does not lose functionality upon remelting.

- This reduces waste and manufacturing costs, aligning with sustainability goals.

Real-World Example

In automotive weather seals:

- EPDM rubber and polypropylene are dynamically vulcanized to form TPV.

- Additives like UV stabilizers and colorants are blended in.

- Extrusion is used to produce continuous sealing strips.

- Final testing ensures flexibility in extreme temperatures (-40°C to +120°C).

Properties of Thermoplastic Elastomers (TPE)

Thermoplastic Elastomers (TPEs) are valued for their balanced properties—offering the elasticity of rubber with the processing advantages of plastics. Understanding these properties is crucial for engineers, designers, and researchers when selecting TPE for specific applications. These properties can be classified into mechanical, thermal, chemical, and environmental aspects.

Mechanical Properties

Elasticity & Flexibility

- TPEs stretch up to 500–1000% elongation (depending on grade).

- They return to their original shape after deformation (rubber-like resilience).

- Example: Used in grips, seals, and footwear for comfort and flexibility.

Hardness Range

- Measured using Shore A (soft) and Shore D (hard).

- TPEs range from super-soft gels (~Shore 5A) to rigid elastomers (~Shore 70D).

- This wide range allows customization for soft-touch grips or durable housings.

Tensile Strength & Tear Resistance

- Typical tensile strength: 5–30 MPa.

- Tear resistance is lower than vulcanized rubber but sufficient for most applications.

- TPUs and COPEs have higher toughness compared to SBCs or TPOs.

Compression Set

- TPVs and TPUs show superior performance in gaskets and seals.

- TPEs exhibit moderate compression set resistance—better than plastics but lower than vulcanized rubber.

Thermal Properties

Melting and Softening Behavior

- Unlike rubber, TPEs soften at elevated temperatures, allowing remelting.

- Typical service temperature: -60°C to +120°C (varies by type).

- High-performance grades (TPU, COPE, PEBA) can withstand up to 150–180°C.

Glass Transition Temperature (Tg)

- Soft segments: Very low Tg (~ -60°C), ensuring flexibility at low temperatures.

- Hard segments: Higher Tg (50–100°C), providing structural stability.

Heat Aging Resistance

- SBCs degrade faster at high temperatures (>90°C).

- TPVs and TPUs show excellent thermal stability.

Chemical Properties

Resistance to Oils and Chemicals

- TPVs, TPUs, and COPEs resist oils, fuels, and solvents well.

- SBCs have poor oil and solvent resistance, limiting use in automotive.

Resistance to Water and Weathering

- TPEs generally resist water absorption.

- UV stability varies: SBCs need stabilizers, while TPVs and TPUs show superior weathering resistance.

Compatibility

- This adhesion property is widely used in grips, handles, and housings.

- TPEs can be overmolded onto rigid plastics like PP, ABS, or PC, creating multi-material products.

Environmental Properties

Recyclability

- Unlike thermoset rubber, TPE is fully recyclable.

- Scrap from molding processes can be re-melted and reused.

- This aligns with circular economy principles.

Light weighting Advantage

- TPEs have lower density (0.9–1.3 g/cm³) compared to rubber (1.2–1.5 g/cm³).

- Helps reduce vehicle weight in automotive applications, improving fuel efficiency.

Non-toxic and Safe Alternatives

- Medical-grade TPEs are free from PVC, phthalates, and latex allergens.

- Preferred in healthcare devices, baby products, and food-contact materials.

Environmental Durability

- TPVs and TPUs are especially durable in harsh environments.

- Resistance to ozone, UV, and weathering makes TPE suitable for outdoor uses (roofing, cables, seals).

Property Comparison Between TPE Types

| Property | SBC/TPS | TPO | TPV | TPU | COPE | PEBA |

| Elasticity | High | Moderate | High | Very High | High | Very High |

| Oil/Fuel Resistance | Poor | Moderate | Good | Excellent | Excellent | Good |

| Heat Resistance | Low | Moderate | High | High | High | Very High |

| Hardness Range | Wide | Moderate | Wide | Wide | Moderate | Wide |

| Recyclability | Excellent | Excellent | Excellent | Good | Good | Good |

| Cost | Low | Moderate | Moderate | High | High | High |

Real-World Example

- Medical tubing (TPE): Flexible at body temperature, sterilizable, and biocompatible.

- Car bumper (TPO): Durable, impact-resistant, and recyclable.

- Phone case (TPU): Soft-touch, shock-absorbing, and abrasion-resistant.

Types and Grades of Thermoplastic Elastomers (TPE)

Thermoplastic elastomers (TPE) are versatile materials combining the elasticity of rubber with the processing ease of plastics. TPEs are categorized into several types based on their chemical composition and structure, each offering unique properties for specific applications:

- Styrenic Block Copolymers (SBC/SBS/SEBS): These are the most common TPEs, featuring a combination of styrene and butadiene or ethylene-butylene blocks. They offer excellent flexibility, soft touch, and weather resistance, making them ideal for consumer goods, grips, and soft-touch automotive components.

- Thermoplastic Polyolefins (TPO/TPE-O): Comprising polypropylene blended with elastomers, TPOs are highly durable, UV-resistant, and economical. They are widely used in automotive bumpers, seals, and roofing membranes.

- Thermoplastic Vulcanizates (TPV): TPVs are dynamically vulcanized blends of rubber and plastic, combining rubber-like elasticity with thermoplastic processability. They exhibit excellent heat resistance, chemical resistance, and long-term durability, suitable for seals, hoses, and automotive weatherstripping.

- Thermoplastic Polyurethanes (TPU): TPUs provide superior abrasion, impact, and chemical resistance with excellent elasticity. Applications include footwear, hoses, cables, and medical devices.

- Copolyester and Copolyamide Elastomers (COPE/CO-PA): These offer high strength, chemical resistance, and thermal stability, often used in automotive fuel systems and industrial tubing.

Grades of TPE within each type vary based on hardness (Shore A/D), tensile strength, elongation, and processing requirements. Selecting the right grade ensures optimal performance in specific applications, whether flexibility, durability, or aesthetic finish is the priority.

Applications of of Thermoplastic Elastomers (TPE)

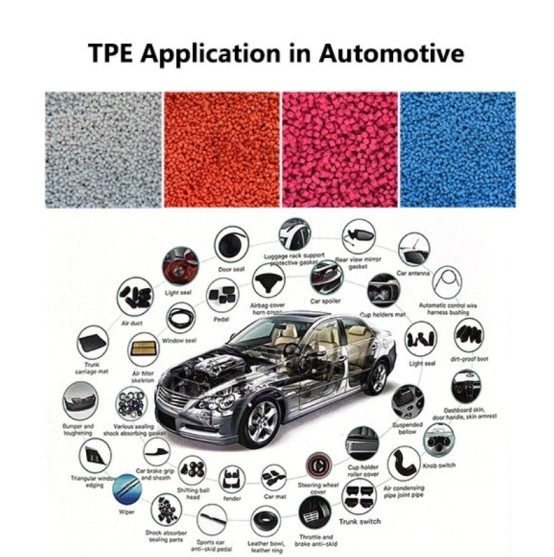

Automotive Industry

- Soft-touch interior parts: dashboards, door panels, armrests.

- Seals, gaskets, and weatherstripping.

- Cable insulation and flexible tubing.

- Bumper covers and anti-vibration mounts.

Consumer Products

- Grips for pens, tools, and sports equipment.

- Kitchen utensils, toothbrushes, and household items.

- Toys and ergonomic designs with soft-touch finishes.

Medical Sector

- Tubing, catheters, and seals.

- Wearable medical devices and protective components.

- Safe for patient contact due to biocompatibility.

Electrical and Electronics

- Cable jackets and connectors.

- Flexible circuits and protective casings.

- Provides insulation, flexibility, and durability.

Footwear Industry

- Shoe soles and midsoles.

- High-performance sports shoes using TPUs for abrasion resistance.

Packaging and Construction

- Flexible films and membranes.

- Sealing solutions for packaging and construction joints.

Industrial Applications

- Hoses, tubes, and protective covers.

- Components requiring chemical and thermal resistance.

Miscellaneous

- Soft-touch coatings for gadgets and household items.

- Lightweight, durable alternatives to traditional rubber components.

Advantages of Thermoplastic Elastomers (TPE)

Advantages of Thermoplastic Elastomers (TPE)

- Flexibility and Elasticity – Combines rubber-like stretch with easy processing like plastics.

- Lightweight – Reduces overall product weight, ideal for automotive and consumer applications.

- Durability – High resistance to wear, tear, and fatigue ensures long service life.

- Chemical Resistance – Resistant to oils, solvents, and many chemicals, suitable for industrial applications.

- Temperature Tolerance – Performs well across a wide temperature range without losing properties.

- Recyclability – Can be melted and reprocessed, making it environmentally friendly.

- Cost-Effective – Easier to process than traditional rubber, reducing manufacturing costs.

- Design Flexibility – Can be injection-molded into complex shapes and colored easily.

- Soft-Touch Feel – Ideal for consumer products requiring ergonomic and comfortable surfaces.

- Lightweight Sealing – Excellent for gaskets, seals, and weatherstripping in automotive and industrial uses.

- Abrasion and Impact Resistance – Withstands repeated stress and mechanical wear.

- Noise and Vibration Reduction – Helps in damping vibrations and reducing operational noise.

Limitations of Thermoplastic Elastomers (TPE)

Limitations of Thermoplastic Elastomers (TPE)

- Lower Heat Resistance

- TPEs generally have lower continuous-use temperature limits compared to vulcanized rubber, which restricts their use in high-temperature applications.

- Limited Chemical Resistance

- Certain TPEs are sensitive to oils, solvents, and aggressive chemicals, which may cause swelling, softening, or degradation.

- Lower Mechanical Strength

- TPEs typically have lower tensile strength and tear resistance than traditional rubber, making them less suitable for heavy-duty or load-bearing applications.

- Creep and Deformation

- Under continuous stress or load, some TPE grades may exhibit creep or permanent deformation over time.

- Cost Considerations

- High-performance TPEs like TPUs or TPVs can be more expensive than standard rubbers for large-scale, low-cost applications.

- UV and Weather Sensitivity

- Some TPE types may degrade, discolor, or lose flexibility when exposed to prolonged UV radiation or harsh outdoor environments unless stabilized with additives.

- Processing Sensitivity

- Improper processing temperatures or techniques can cause degradation, shrinkage, or inconsistent properties in finished parts.

- Limited Hardness Range

- Certain TPE families have a narrower Shore hardness range compared to other elastomers, limiting flexibility in some applications.

Despite these limitations, Thermoplastic Elastomers (TPEs) are widely used due to their recyclability, design versatility, and combination of plastic and rubber properties, making them suitable for many automotive, consumer, medical, and industrial applications.

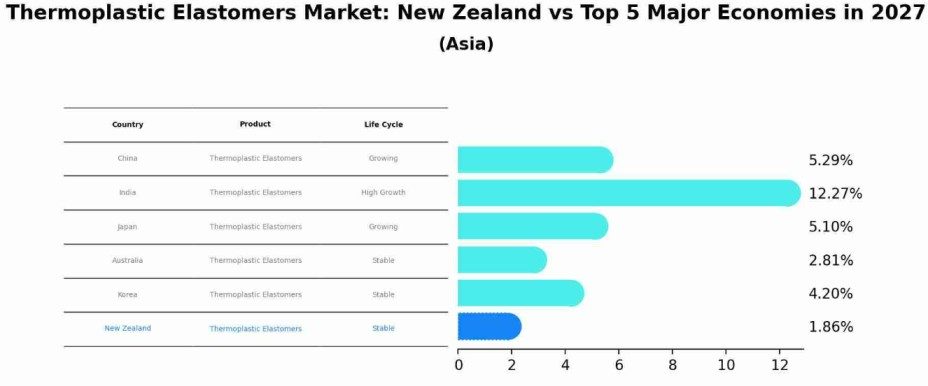

Thermoplastic Elastomers (TPE) : Global Market Trend

Overall Market Trend

- Global TPE market valued around USD 30–32 billion in 2024.

- Expected CAGR of 4.5%–6% till 2030.

- Growth driven by automotive, medical, consumer goods, and electronics industries.

- Increasing shift toward lightweight, recyclable, and eco-friendly materials.

Top 6 Countries/Regions Market Trends

China

- Largest producer and consumer of TPE.

- Strong demand from automotive and footwear sectors.

- Heavy investments in infrastructure and consumer goods.

United States of America

- Demand led by medical devices, automotive, and electronics.

- Strong presence of innovation and R&D in specialty TPE grades.

Germany

- Major hub for automotive TPE applications.

- Growing focus on sustainability and green materials.

- Increasing demand for high-performance TPUs.

Japan

- Strong demand in electronics, robotics, and automotive.

- Known for high-quality precision TPE products.

India

- Rapidly growing market due to automotive manufacturing expansion.

- Rising demand for consumer goods and footwear applications.

South Korea

- Significant use in electronics, semiconductors, and automotive.

- Innovation-driven demand for TPU and specialty elastomers.

Future Outlook

- Automotive lightweighting and electric vehicle (EV) adoption will drive TPE demand.

- Medical-grade Thermoplastic Elastomers (TPE) expected to rise with healthcare expansion.

- Shift toward bio-based and recyclable TPEs to align with global sustainability goals.

- Asia-Pacific will remain the fastest-growing market.

Conclusion

Thermoplastic Elastomers (TPE) have emerged as one of the most versatile materials, combining the flexibility of rubber with the processability of plastics. Their wide range of grades, excellent recyclability, and ability to meet diverse industry requirements make them a preferred choice over traditional elastomers. From automotive and medical applications to consumer goods and electronics, TPE continues to expand its presence across sectors.

With strong market growth in China, the U.S., Germany, Japan, India, and South Korea, the global outlook for Thermoplastic Elastomers (TPE) remains highly promising. The future will be shaped by increasing demand for lightweight, sustainable, and high-performance materials, especially in electric vehicles, healthcare, and eco-friendly consumer products.

In summary, TPE stands at the forefront of innovation, sustainability, and industrial growth—proving itself as a material of the future.

FAQs

What are Thermoplastic Elastomers (TPE)?

- Polymers combining rubber-like elasticity with plastic processability.

- Re-moldable and recyclable.

What are the main types of Thermoplastic Elastomers (TPE)?

- SBC (Styrenic Block Copolymers)

- TPO (Thermoplastic Olefins)

- TPV (Thermoplastic Vulcanizates)

- TPU (Thermoplastic Polyurethanes)

- COPE (Copolyester Elastomers)

- COPA (Copolyamide Elastomers)

How are Thermoplastic Elastomers (TPE) grades classified?

- Based on hardness (Shore A/D).

- Vary in tensile strength, elongation, and flexibility.

What are the key uses of Thermoplastic Elastomers (TPE)?

- Automotive: seals, bumpers, interiors.

- Medical: tubing, catheters, seals.

- Consumer goods: grips, toys, utensils.

- Electronics: cables, connectors.

Why is Thermoplastic Elastomers (TPE) preferred over traditional rubber?

- No vulcanization needed.

- Faster processing, lower cost.

- Recyclable and versatile.

Is Thermoplastic Elastomers (TPE) suitable for outdoor use?

- Yes, UV- and weather-resistant grades available.

- Ideal for roofing membranes, cables, seals.

What is the global market outlook for Thermoplastic Elastomers (TPE)?

- Market size ~USD 31 billion (2024).

- Expected CAGR ~5% till 2030.

- Asia-Pacific dominates demand.

Are Thermoplastic Elastomers (TPEs) eco-friendly?

- Yes, recyclable and reusable.

- Lower environmental impact than rubber.

Can Thermoplastic Elastomers (TPE) be used in 3D printing?

- Yes, flexible filaments available.

- Used for prototypes and soft parts.

Which industries drive Thermoplastic Elastomers (TPE) demand?

- Automotive (lightweighting trend).

- Medical (biocompatibility).

- Electronics (flexible insulation).

- Footwear & consumer goods.

- Thermoplastic Elastomers (TPE) Material Explained: Types, Properties, Applications & Market

- Comprehensive Guide on Thermoplastic Olefin (TPO) Material – Point-to-Point Explanation

- All-in-One Hot Runner Mold Repair and Troubleshooting Manual

- Comprehensive guide on EPDM in Transfer Molding: Definition, Composition, Manufacturing, Shelf Life, Properties, Pros & Cons, Applications, FAQs.

- Mold Preventive Maintenance Checksheet

Everything is very open with a precise description of the challenges.

It was really informative. Your website is very helpful.

Many thanks for sharing!

Appreciation received from peoples like you motivate me to work more

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.

You made some decent points there. I regarded on the web for the difficulty and found most individuals will go along with together with your website.

helloI really like your writing so a lot share we keep up a correspondence extra approximately your post on AOL I need an expert in this house to unravel my problem May be that is you Taking a look ahead to see you

This blog is definitely rather handy since I’m at the moment creating an internet floral website – although I am only starting out therefore it’s really fairly small, nothing like this site. Can link to a few of the posts here as they are quite. Thanks much. Zoey Olsen

I carry on listening to the newscast speak about getting boundless online grant applications so I have been looking around for the top site to get one. Could you advise me please, where could i find some?

Spot on with this write-up, I truly suppose this website needs much more consideration. I’ll in all probability be again to read much more, thanks for that info.

Merely wanna say that this is very helpful, Thanks for taking your time to write this.

magnificent points altogether, you just gained a new reader. What would you recommend in regards to your post that you made a few days ago? Any positive?

Thank you for sharing with us, I think this website genuinely stands out : D.

Can I just say what a relief to find someone who actually knows what theyre talking about on the internet. You definitely know how to bring an issue to light and make it important. More people need to read this and understand this side of the story. I cant believe youre not more popular because you definitely have the gift.

I think you have noted some very interesting details, regards for the post.

you’re actually a good webmaster. The web site loading velocity is incredible. It sort of feels that you are doing any distinctive trick. Moreover, The contents are masterpiece. you have done a fantastic activity in this topic!

Howdy very cool website!! Guy .. Excellent .. Superb .. I will bookmark your website and take the feeds additionally?KI’m satisfied to find numerous helpful info right here in the publish, we need work out more strategies in this regard, thank you for sharing. . . . . .

I enjoy your writing style really loving this internet site.

Great goods from you, man. I have have in mind your stuff previous to and you’re just extremely great. I actually like what you have bought right here, really like what you’re stating and the best way through which you say it. You’re making it entertaining and you still care for to stay it smart. I can not wait to learn far more from you. That is actually a great website.

I was looking through some of your content on this website and I think this website is rattling informative! Retain posting.

I view something really interesting about your site so I saved to my bookmarks.

great points altogether, you just gained a brand new reader. What would you recommend about your post that you made some days ago? Any positive?

Terrific work! This is the type of info that should be shared around the internet. Shame on Google for not positioning this post higher! Come on over and visit my website . Thanks =)

I am continuously looking online for ideas that can facilitate me. Thx!

I believe this site contains some real great info for everyone. “I prefer the wicked rather than the foolish. The wicked sometimes rest.” by Alexandre Dumas.

But a smiling visitor here to share the love (:, btw outstanding design.

Wow!! I’m honestly amazed by how good this was!

This is the kind of article people bookmark for later.

You have a remarkable way of connecting ideas.

I’m blown away by the value in this post.

This made me feel genuinely motivated — thank you!

I learned so many new things from this article.

I can’t stop smiling — this post made my day!

This was exactly what I needed to read today.

You’ve turned a complicated topic into something enjoyable.

The quality of your writing is outstanding.

Another excellent post — you never disappoint!

Utterly composed subject matter, Really enjoyed reading.

Awsome info and right to the point. I am not sure if this is really the best place to ask but do you people have any ideea where to get some professional writers? Thanks 🙂

Hello there! Would you mind if I share your blog with my facebook group? There’s a lot of people that I think would really enjoy your content. Please let me know. Thank you

Well I really liked studying it. This post procured by you is very effective for good planning.

I have not checked in here for some time as I thought it was getting boring, but the last few posts are great quality so I guess I¦ll add you back to my everyday bloglist. You deserve it my friend 🙂

Good article and right to the point. I am not sure if this is actually the best place to ask but do you folks have any ideea where to employ some professional writers? Thanks in advance 🙂

You have brought up a very superb details, thankyou for the post.

I have not checked in here for a while since I thought it was getting boring, but the last several posts are good quality so I guess I’ll add you back to my everyday bloglist. You deserve it my friend 🙂

After examine a couple of of the weblog posts in your website now, and I actually like your manner of blogging. I bookmarked it to my bookmark web site listing and shall be checking back soon. Pls try my web site as properly and let me know what you think.

This post practically sparkles — incredible writing!

I have read some good stuff here. Certainly worth bookmarking for revisiting. I surprise how much effort you put to create such a fantastic informative web site.

This was so well organized and easy to understand.

I have read several just right stuff here. Definitely value bookmarking for revisiting. I surprise how a lot effort you place to create the sort of great informative site.

I’d constantly want to be update on new articles on this website , saved to favorites! .

Very efficiently written article. It will be supportive to anybody who employess it, as well as yours truly :). Keep up the good work – for sure i will check out more posts.

Your ability to explain things is truly impressive.

You’ve created something truly valuable here.

Really excellent info can be found on web blog.

You have an incredible ability to communicate complex ideas.

Your vibrant approach is absolutely refreshing — great work!

This content shines so brightly — incredible effort!

I have been examinating out many of your stories and i can claim nice stuff. I will surely bookmark your website.

Amazing content! I’m so glad I found this post.

This might be your most exciting post yet — WOW!

This is why I love following your content.

I like this web blog so much, saved to favorites. “Respect for the fragility and importance of an individual life is still the mark of an educated man.” by Norman Cousins.

This was a fantastic read — well done!

I appreciate the thoughtfulness in everything you write.

A person essentially help to make seriously posts I would state. This is the first time I frequented your website page and thus far? I amazed with the research you made to create this particular publish incredible. Wonderful job!

This post was a joy to read — thank you!

You captured this topic perfectly.

You’ve taken this topic to a whole new level — amazing!

I appreciate the thoughtfulness in everything you write.

I really appreciate this post. I have been looking all over for this! Thank goodness I found it on Bing. You have made my day! Thx again

This is one of the best explanations I’ve come across on this topic.

Such a high-energy, beautifully written piece!

You consistently offer such high-quality information.

This was a total joy to read — loved every second!

I’m consistently impressed by the quality of your work.

Thanks on your marvelous posting! I genuinely enjoyed reading it, you may be a great author.I will always bookmark your blog and will come back at some point. I want to encourage you to definitely continue your great writing, have a nice morning!

good post.Never knew this, regards for letting me know.

I truly appreciate this post. I¦ve been looking all over for this! Thank goodness I found it on Bing. You have made my day! Thank you again

I genuinely appreciate your piece of work, Great post.

Its like you read my mind! You appear to know so much about this, like you wrote the book in it or something. I think that you could do with a few pics to drive the message home a bit, but other than that, this is wonderful blog. A fantastic read. I’ll definitely be back.

you’re really a good webmaster. The web site loading speed is incredible. It seems that you are doing any unique trick. Furthermore, The contents are masterwork. you have done a wonderful job on this topic!

Oh my goodness! a tremendous article dude. Thanks However I’m experiencing issue with ur rss . Don’t know why Unable to subscribe to it. Is there anybody getting equivalent rss drawback? Anybody who is aware of kindly respond. Thnkx

Hey there, You have done a fantastic job. I will certainly digg it and individually recommend to my friends. I’m sure they’ll be benefited from this site.

There is noticeably a bundle to know about this. I assume you made certain good factors in options also.

Hello. fantastic job. I did not imagine this. This is a splendid story. Thanks!

you’re really a good webmaster. The website loading speed is incredible. It seems that you’re doing any unique trick. Also, The contents are masterwork. you have done a excellent job on this topic!

You have brought up a very superb details , appreciate it for the post.

Have you ever thought about publishing an ebook or guest authoring on other blogs? I have a blog based on the same ideas you discuss and would love to have you share some stories/information. I know my subscribers would appreciate your work. If you’re even remotely interested, feel free to send me an e-mail.

Really enjoyed this article, is there any way I can receive an email whenever there is a new article?

This website is my breathing in, rattling wonderful design and perfect subject matter.

I have been exploring for a bit for any high-quality articles or blog posts on this sort of house . Exploring in Yahoo I at last stumbled upon this web site. Reading this info So i?¦m glad to convey that I have a very just right uncanny feeling I came upon exactly what I needed. I such a lot without a doubt will make sure to do not overlook this site and provides it a glance regularly.

Saved as a favorite, I really like your blog!

This was incredibly eye-opening — thank you!

This hit me with pure positivity — THANK YOU!

Some truly interesting details you have written.Helped me a lot, just what I was searching for : D.

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

Hello my loved one! I want to say that this post is awesome, nice written and come with approximately all vital infos. I’d like to see extra posts like this .

Hello.This article was really fascinating, particularly since I was looking for thoughts on this matter last couple of days.

This is exactly the type of information I needed today.

I’ve been exploring for a little for any high quality articles or blog posts on this sort of space . Exploring in Yahoo I finally stumbled upon this website. Studying this information So i’m glad to convey that I have an incredibly good uncanny feeling I discovered just what I needed. I most indisputably will make certain to don’t forget this website and give it a look on a continuing basis.

This was incredibly eye-opening — thank you!

I’m honestly amazed at how fun this was to read!

Thankyou for all your efforts that you have put in this. very interesting information.

This is very attention-grabbing, You’re a very professional blogger. I’ve joined your rss feed and look ahead to seeking extra of your fantastic post. Additionally, I’ve shared your site in my social networks!

Every line felt alive — incredible writing!

Great write-up, I’m regular visitor of one’s blog, maintain up the excellent operate, and It is going to be a regular visitor for a long time.

I like what you guys are up too. Such clever work and reporting! Carry on the superb works guys I¦ve incorporated you guys to my blogroll. I think it will improve the value of my site 🙂

The enthusiasm in this post is NEXT LEVEL — amazing job!

I’ll definitely be reading more from you.

I’m genuinely hyped after reading this — incredible!

Your posts always leave me thinking.

Your passion for the topic really shines through.

This was brilliant — thank you for sharing it.

Every sentence bursts with enthusiasm — love it!

Very interesting points you have remarked, thankyou for posting. “In a great romance, each person plays a part the other really likes.” by Elizabeth Ashley.

This is the kind of content that makes people fall in love with learning!

I’m seriously impressed — this post is next-level!

Hi there, I found your site via Google while looking for a related topic, your website came up, it looks good. I have bookmarked it in my google bookmarks.

Have you ever thought about adding a little bit more than just your articles? I mean, what you say is important and everything. But think of if you added some great photos or video clips to give your posts more, “pop”! Your content is excellent but with images and videos, this site could definitely be one of the greatest in its niche. Very good blog!

sure

Hello there, simply was alert to your blog through Google, and found that it’s really informative. I’m gonna be careful for brussels. I’ll appreciate if you happen to proceed this in future. Numerous other folks will probably be benefited out of your writing. Cheers!

Hello! Would you mind if I share your blog with my twitter group? There’s a lot of folks that I think would really enjoy your content. Please let me know. Thank you

I appreciate how practical and actionable your content is.

This is exactly the energy I needed today!

There’s so much life in your writing — incredible work!

I admire the clarity and depth in your writing.

Outstanding post, I conceive blog owners should acquire a lot from this website its rattling user friendly.

This post was absolutely fantastic from start to finish.

Every line felt alive — incredible writing!

Your enthusiasm makes learning fun — brilliant job!

Mind-blowingly good — keep these coming!

This was such a well-structured and thoughtful read.

Your house is valueble for me. Thanks!…

Hi , I do believe this is an excellent blog. I stumbled upon it on Yahoo , i will come back once again. Money and freedom is the best way to change, may you be rich and help other people.

Would love to perpetually get updated outstanding site! .

Immerse yourself in a fascinating world [url=https://new-aviator-game.com/]aviator[/url] and experience your passion right now!

Whether you’re an expert or just starting, this game is worth checking out.

I am pleased that I observed this site, just the right info that I was looking for! .

I’m impressed, I need to say. Actually hardly ever do I encounter a blog that’s both educative and entertaining, and let me inform you, you could have hit the nail on the head. Your thought is outstanding; the issue is one thing that not sufficient persons are speaking intelligently about. I’m very completely happy that I stumbled across this in my search for something regarding this.

I’ll definitely be reading more from you.

You’ve absolutely nailed it — incredible writing!

I appreciate the positive energy you bring to your posts.

Your writing is a powerhouse of enthusiasm — great job!

Your energy is absolutely infectious — love it!

You’ve crafted such a thoughtful and detailed piece.

This is one of the most helpful articles I’ve seen recently.

You’ve absolutely nailed it — incredible writing!

This was such a refreshing and helpful read.

Good write-up, I am regular visitor of one’s web site, maintain up the excellent operate, and It’s going to be a regular visitor for a lengthy time.

This web site can be a walk-by means of for all of the info you wished about this and didn’t know who to ask. Glimpse right here, and also you’ll positively discover it.

Heya i’m for the first time here. I found this board and I find It really useful & it helped me out much. I hope to give something back and aid others like you aided me.

I admire your piece of work, appreciate it for all the interesting articles.

This is really interesting, You are a very skilled blogger. I’ve joined your feed and look forward to seeking more of your great post. Also, I’ve shared your web site in my social networks!

thanks

The excitement in this post is contagious!

This was such a meaningful and insightful post.

I truly appreciate this post. I have been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thx again

Unquestionably believe that which you stated. Your favorite reason seemed to be on the net the easiest thing to be aware of. I say to you, I certainly get annoyed while people consider worries that they plainly don’t know about. You managed to hit the nail upon the top as well as defined out the whole thing without having side-effects , people can take a signal. Will probably be back to get more. Thanks

I love it when people come together and share opinions, great blog, keep it up.

I really appreciate this post. I have been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thanks again!

I appreciate, cause I found just what I was looking for. You’ve ended my four day long hunt! God Bless you man. Have a great day. Bye

This made a real impact on me — thank you!

Pretty! This was a really wonderful post. Thank you for your provided information.

I am thankful that I discovered this blog, precisely the right info that I was looking for! .

Fantastic site. A lot of useful info here. I am sending it to a few buddies ans additionally sharing in delicious. And certainly, thanks on your effort!

I really appreciate this post. I¦ve been looking everywhere for this! Thank goodness I found it on Bing. You’ve made my day! Thank you again

he blog was how do i say it… relevant, finally something that helped me. Thanks

I really appreciate this post. I’ve been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thanks again

Hi there! This post couldn’t be written any better! Reading through this post reminds me of my previous room mate! He always kept talking about this. I will forward this article to him. Pretty sure he will have a good read. Thank you for sharing!